mems device and its preparation method

A technology of devices and cuboids, which is applied in the field of MEMS devices and its preparation, can solve the problems of increasing the fluctuation range of device sensitivity and signal-to-noise ratio, the relatively large application of the vibrating film, and the loss of the vibrating film, so as to increase the effective vibration area, Improve the sensitivity and signal-to-noise ratio, reduce the effect of amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

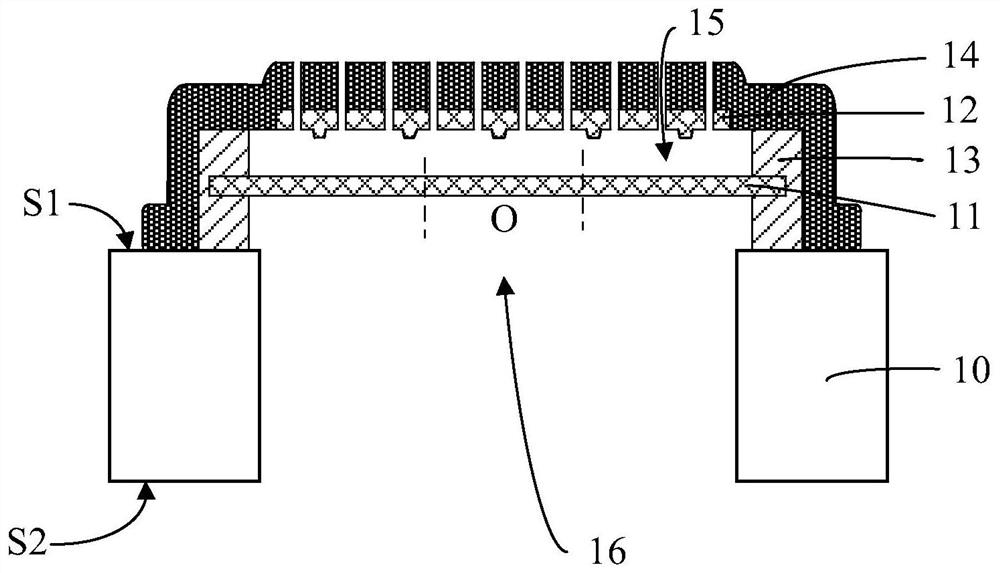

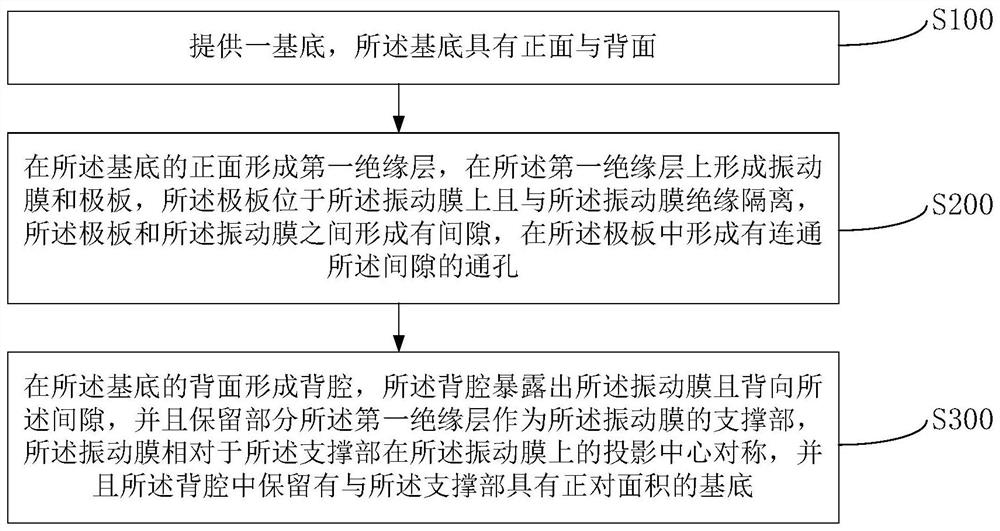

[0049] In view of the above problems, the inventors of the present application proposed a method for preparing a MEMS device, including: providing a substrate, the substrate has a front and a back; forming a first insulating layer on the front of the substrate, and forming a first insulating layer on the first insulating A vibrating film and a pole plate are formed on the layer, the pole plate is located on the vibrating film and is insulated from the vibrating film, a gap is formed between the pole plate and the vibrating film, and a gap is formed in the pole plate There is a through hole communicating with the gap; a back cavity is formed on the back of the substrate, the back cavity exposes the vibrating membrane and faces away from the gap, and retains part of the first insulating layer as the vibrating membrane The supporting part, the vibrating membrane is symmetrical with respect to the projection center of the supporting part on the vibrating membrane, and a base having...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com