Large-diameter corrugated pipe pulverizer and production method thereof

A corrugated pipe and pulverizer technology, applied in grain processing and other directions, to achieve the effect of good wear resistance, avoid entry, and prevent thread jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

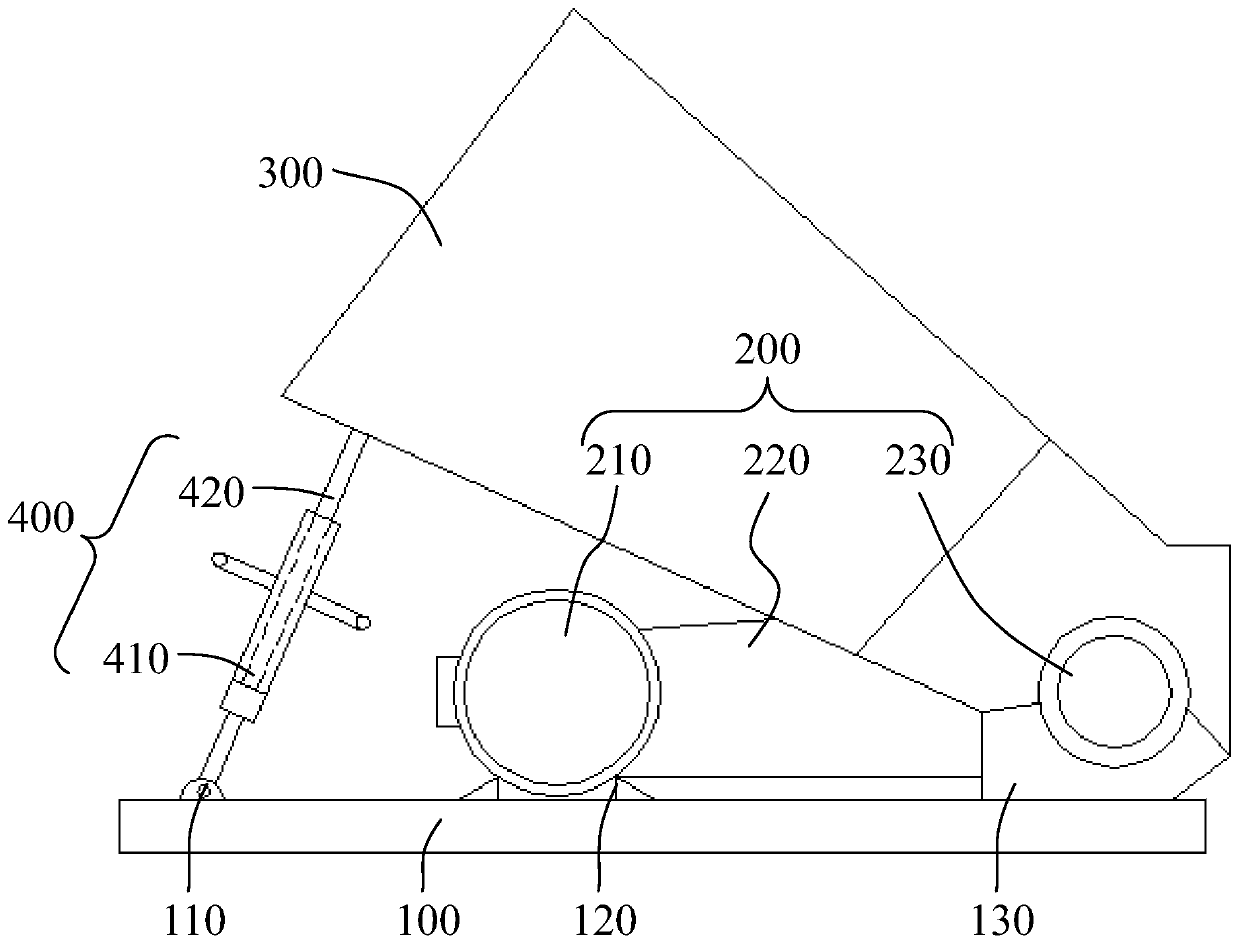

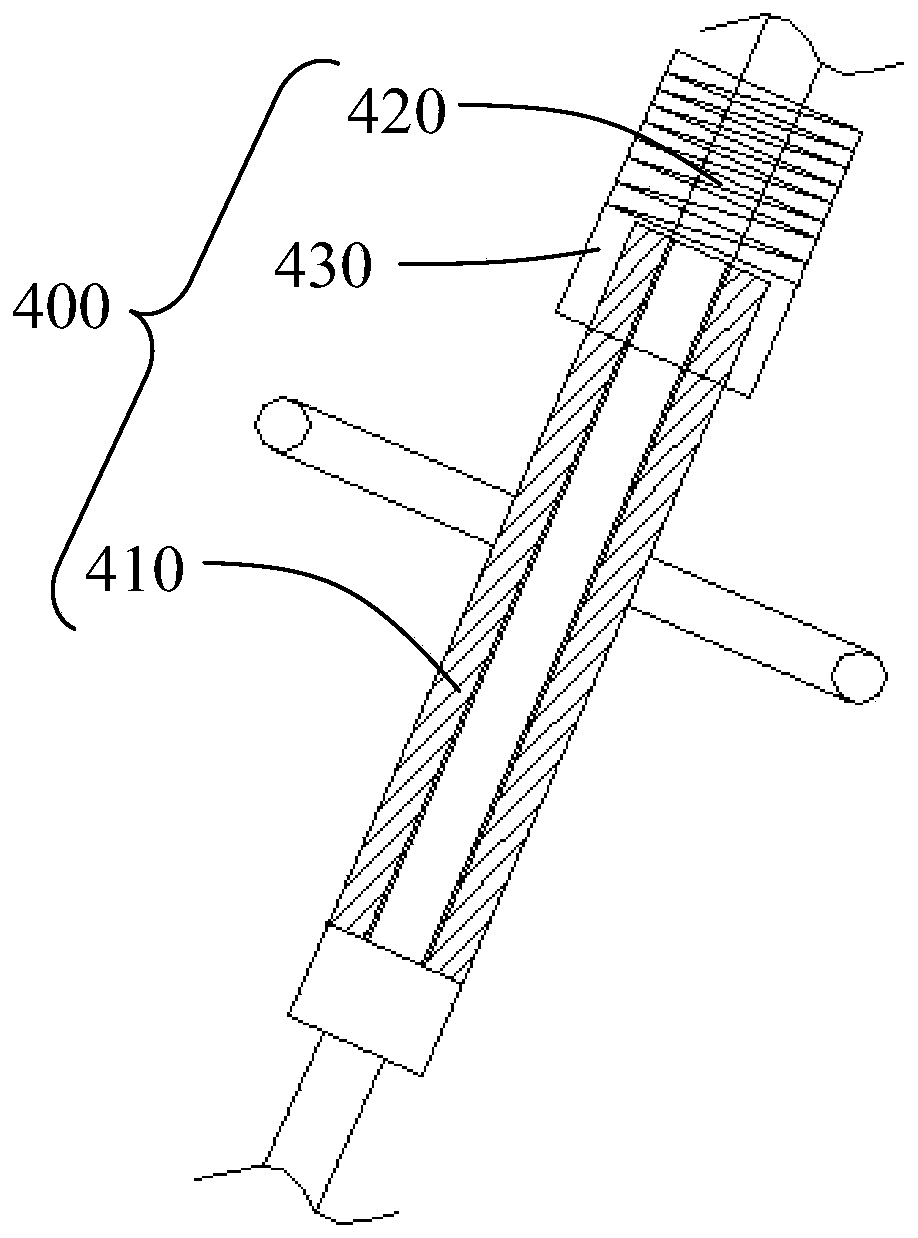

[0041] Such as Figure 1 to Figure 4 As shown, a large-diameter corrugated pipe grinder, the large-diameter corrugated pipe grinder in this embodiment includes a base 100, a crushing mechanism 200, a box body 300, an adjustment rod 400 and a PLC controller (not shown in the figure).

[0042] Such as figure 1As shown, the base 100 of this embodiment has two parallel horizontal end surfaces; the base 100 is made of cast iron, which has good stability, is not easily deformed, and is corrosion-resistant and has a long service life. Even if the liquid flows out, it will not cause rust or the like on the base 100 . The upper end surface of the base 100 is provided with a connecting ear 110, a fixed seat 120 and a rotating seat 130, the connecting ear 110 is used to hinge the sleeve rod 410, the fixed seat 120 is used to fix the servo motor 210, and the rotating seat 130 is used to hinge The box body 300, the connecting ear 110, the fixed seat 120 and the rotating seat 130 are all ...

Embodiment 2

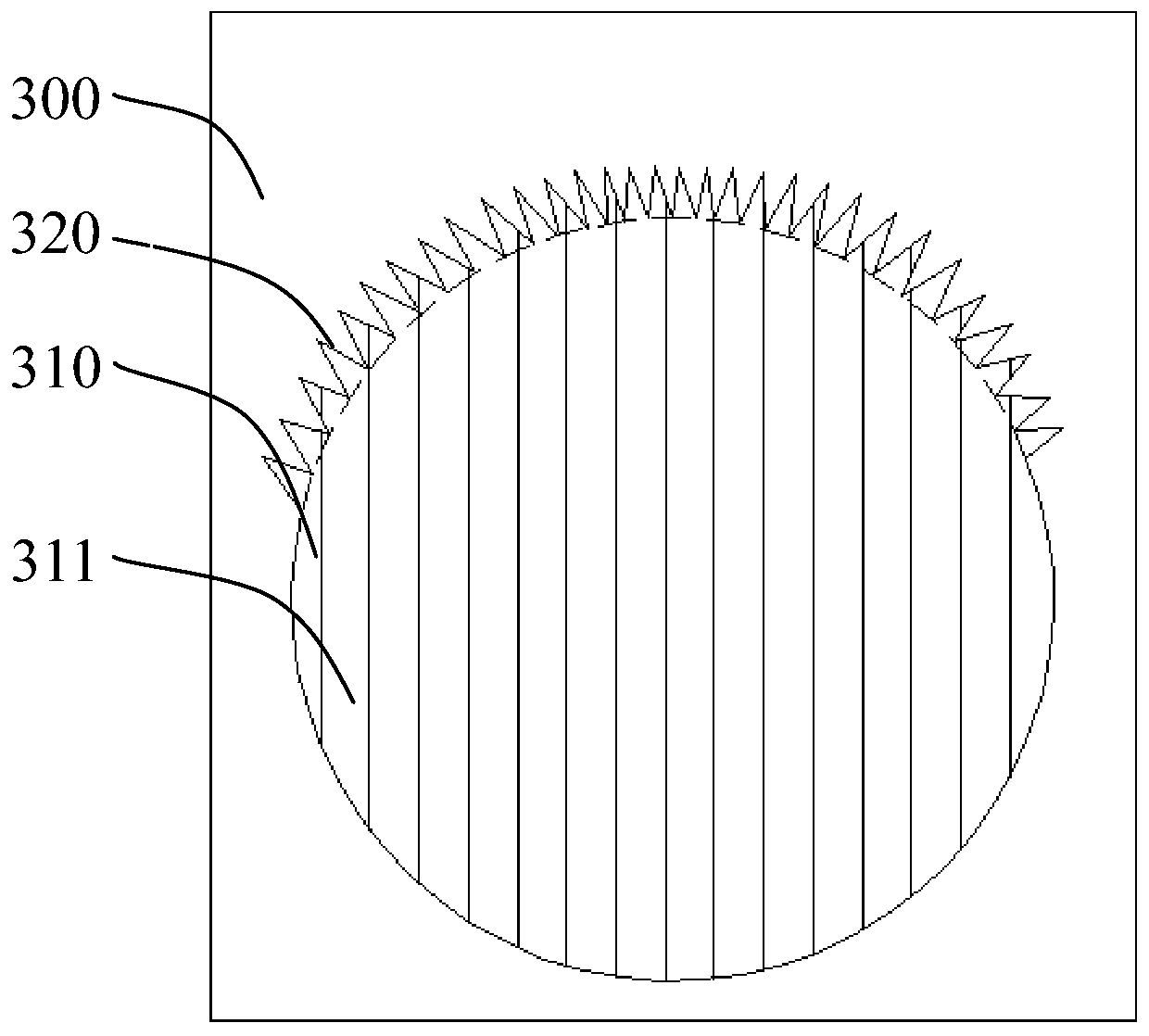

[0053] This embodiment provides a production method of a large-diameter corrugated pipe pulverizer, in which the height of the feed port 310 is adjusted through a height adjustment device, and the corrugated pipe is put into the feed port 310. Control the action of the cylinder 330 to apply a clamping force to the corrugated pipe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com