Fully automatic sponge glue-rolling composite assembly line

An assembly line, fully automatic technology, applied in the direction of layered products, lamination devices, lamination, etc., can solve the problems of high labor intensity, low degree of automation, artificial health effects, etc. The effect of reducing manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

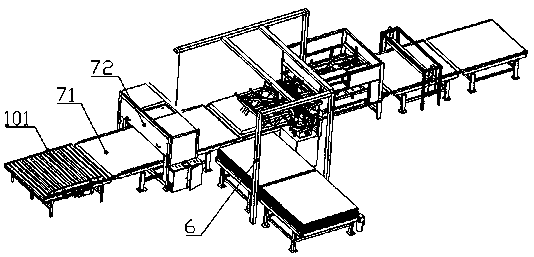

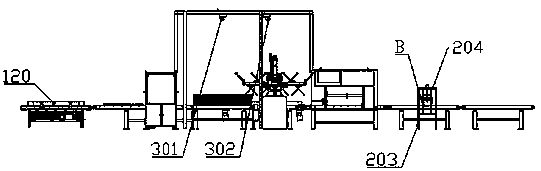

[0042] Such as Figure 1-Figure 13 A fully automatic sponge rolling compound assembly line shown, including

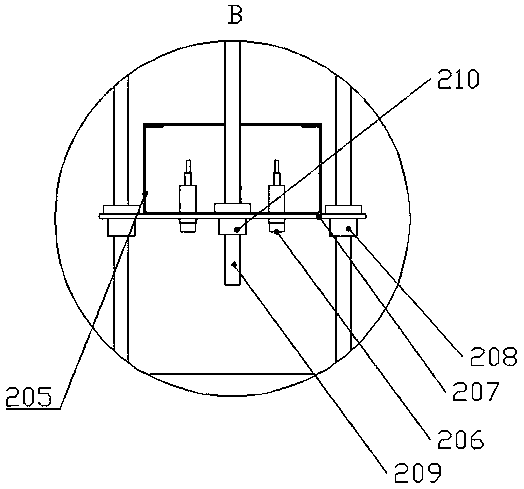

[0043] A composite frame 6, the composite frame 6 is a frame structure composed of several horizontal bars, longitudinal bars and vertical bars, on the composite frame 6 along the conveying direction of the sponge, there are rubber rolling stations, Composite station, pressing station, transfer station, rubber rolling station includes rubber rolling conveyor 71, sponge rubber rolling machine 72, composite station includes composite conveying, detection mechanism, sponge grabbing mechanism, driving sponge grabbing mechanism Mobile robot, wherein the compound conveying includes the main sponge conveying 81 arranged on the compound frame and the auxiliary sponge conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com