Manufacturing method applicable to permanent identifiers of car parts

A production method and technology for automobile parts, which are applied in the directions of printing device, printing, printing plate preparation, etc., can solve the problems of poor marking consistency, low engraving board efficiency, poor anti-counterfeiting function, etc., so as to improve production efficiency and improve economic benefits. Simple and understandable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

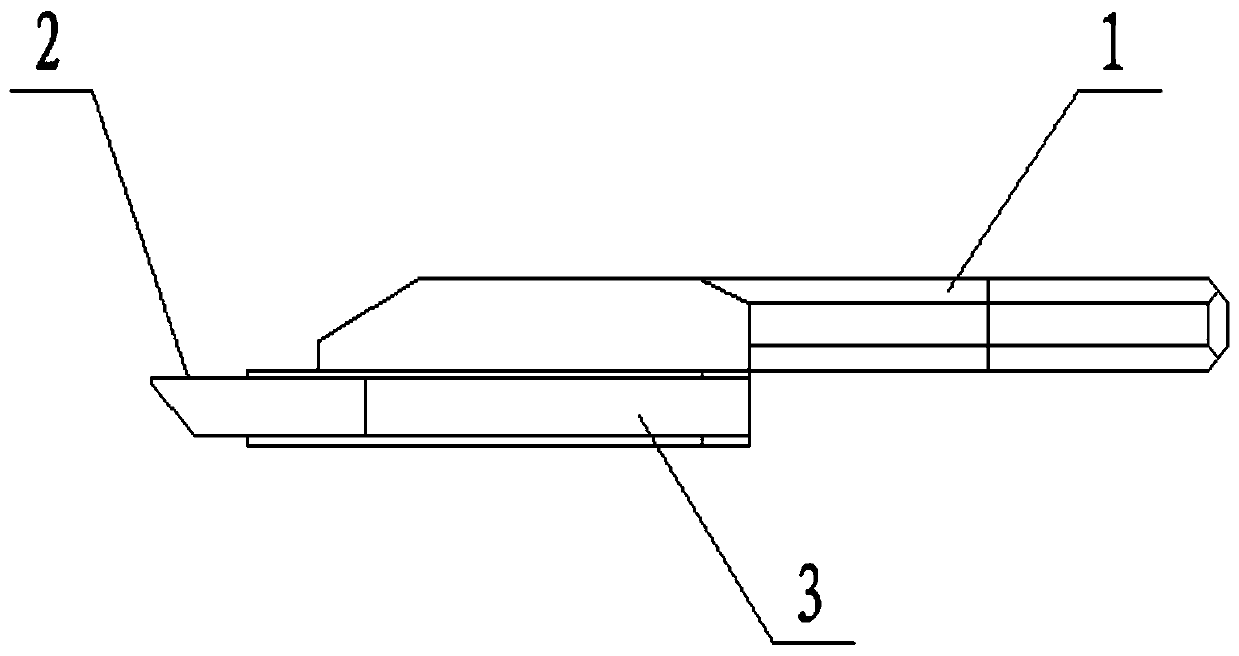

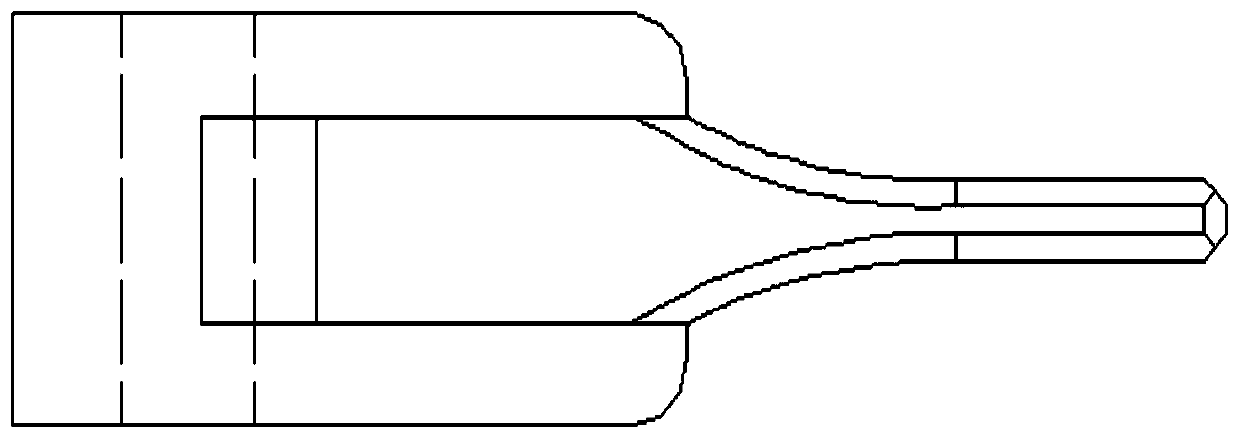

Image

Examples

Embodiment 1

[0029] A manufacturing method suitable for permanent marking of auto parts, the specific steps are as follows:

[0030] Step 1: Edit the word document of the logo on the computer, then use the printer to print out the content of the suspension product logo on the plate-making transfer paper, and cut the screen cloth into an area slightly larger than the frame;

[0031] Step 2: Tighten the screen cloth and nail the screen cloth to the frame, pour photosensitive glue into the stainless steel glue applicator, and then paint on both sides of the screen cloth from bottom to top and from left to right The photosensitive glue is more than three times, and then the frame is dried on the electric heater, which takes six minutes in summer and twelve minutes in winter;

[0032] Step 3: Expose the dried frame in a UV lamp and a closed and light-tight room, then wash and dry the frame, tear off and cut the screen cloth on the dried frame, and then remove the screen The cloth is tightened ...

Embodiment 2

[0035] A manufacturing method suitable for permanent marking of auto parts, the specific steps are as follows:

[0036] Step 1: Print out the content of the suspension product logo on the plate-making transfer paper, and cut the screen cloth to an area slightly larger than the frame;

[0037] Step 2, turn on the small air compressor to inflate, put U-shaped nails on the U-shaped nail gun while inflating, after the air compressor is fully inflated, put the screen cloth in a straight line, and nail a wide side of the screen cloth first , then tighten the other wide side and nail it, then pull one of the long sides and nail it, and finally tighten the last long side and nail it, pour some of the photosensitive glue that has been prepared into the glue applicator, The photosensitive glue is solvent-resistant diazo photosensitive glue. Before opening, it needs to fill 50ml of tap water with a measuring cup in a closed room, pour the photosensitizer and 50ml of water into the wide-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com