K2MgSi5O12 potassium fast ion conductor with Al<3+> and B<3+> synergistically doped and production method of K2MgSi5O12 potassium fast ion conductor with Al<3+> and B<3+> synergistically doped

A ymgbxalysi5-x-yo12, ion conductor technology, applied in the field of solid potassium fast ion conductor manufacturing, to achieve the effect of reducing migration activation energy and grain boundary voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

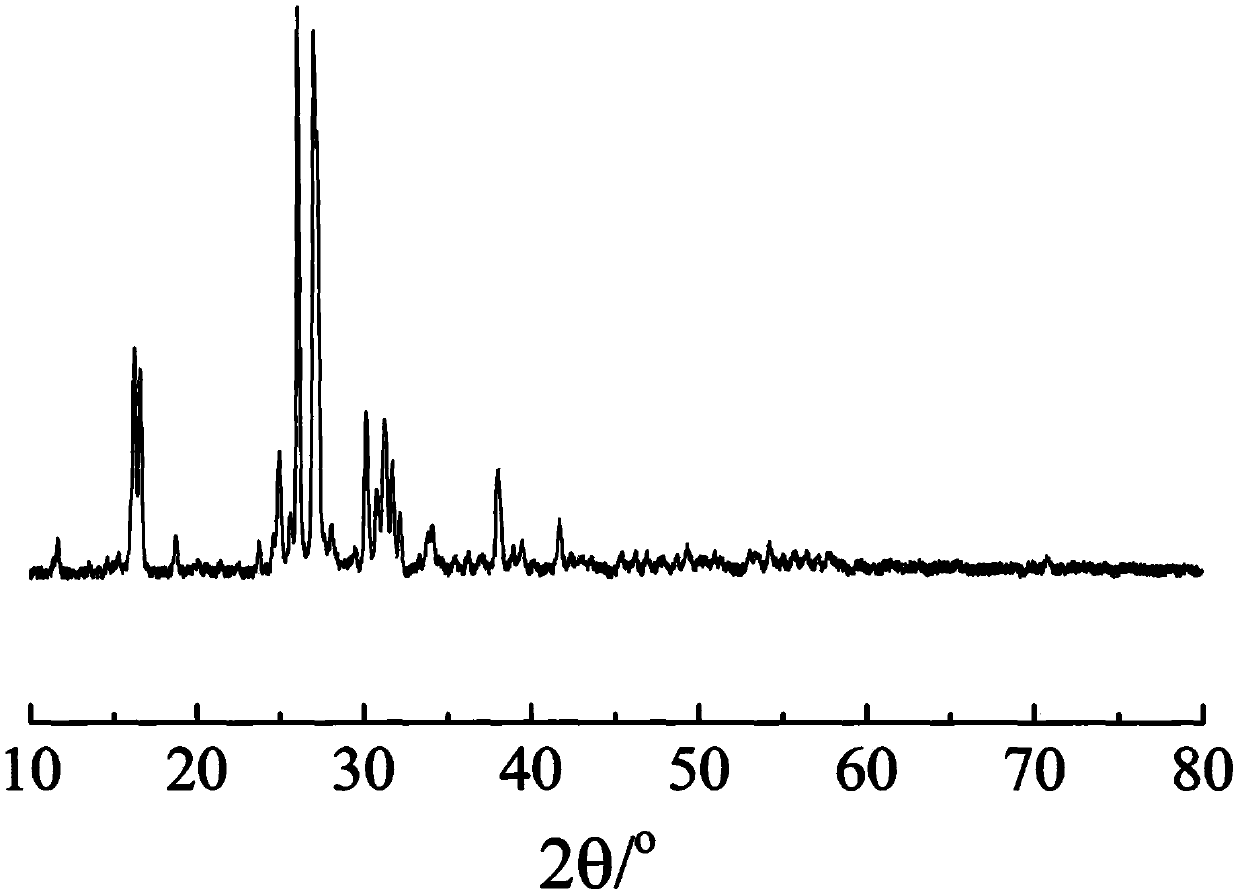

[0011] Embodiment 1: the solid K 2 CO 3 :Al 2 o 3 : SiO 2 :B 2 o 3 : MgO according to K 2.1 MgB 0.05 Al 0.05 Si 4.9 o 12 The ratio of the stoichiometric molar ratio is evenly mixed, adding quality is the dehydrated alcohol of mixture quality 3.2%, in ball mill with the rotating speed ball mill of 120 rev / mins 12 hours, after ball mill finishes, in 60 ℃ of vacuum ovens (gas pressure in the oven is at 3Pa) for 2 hours, take it out and re-grind in an agate mortar for 15 minutes, and the ground powder is heated to 560°C at a rate of 8°C / min in an air atmosphere and then cooled with the furnace after being kept for 3 hours; The powder was ground again in an agate mortar for 10 minutes, and the ground powder was heated to 1250 °C at a rate of 5 °C / min in a platinum crucible in an air atmosphere and kept for 30 hours, then taken out of the furnace and cooled rapidly; the cooled The material was pulverized and ground for 30 minutes in the mill, soaked in 0.1 M sodium hydrox...

Embodiment 2

[0012] Embodiment 2: the solid K 2 CO 3 :Al 2 o 3 : SiO 2 :B 2 o 3 : MgO according to K 2.3 MgB 0.15 Al 0.15 Si 4.7 o 12 The ratio of the stoichiometric molar ratio is evenly mixed, adding quality is the dehydrated alcohol of mixture quality 9%, in ball mill with the rotating speed ball mill of 480 rev / mins 43 hours, after ball mill finishes, in 115 ℃ of vacuum ovens (gas pressure in oven is at 15Pa) for 10 hours, take it out and re-grind in an agate mortar for 30 minutes, heat up the ground powder to 650°C at a rate of 30°C / min in an air atmosphere, and then cool it with the furnace for 10 hours; The powder was ground again in an agate mortar for 30 minutes, and the ground powder was heated to 1350°C in a platinum crucible in an air atmosphere at a rate of 12°C / min and kept at 1350°C for 45 hours, then taken out of the furnace and cooled rapidly; the cooled The material was pulverized and ground for 45 minutes in the mill, soaked in 0.3M sodium hydroxide solution f...

Embodiment 3

[0013] Embodiment 3: the solid K 2 CO 3 : Al 2 o 3 : SiO 2 :B 2 o 3 : MgO according to K 2.15 MgB 0.07 Al 0.08 Si 4.85 o 12 The ratio of the stoichiometric molar ratio is evenly mixed, adding quality is the dehydrated alcohol of mixture quality 6%, in ball mill with the rotating speed ball mill of 370 rev / mins 25 hours, after ball mill finishes, in 100 ℃ of vacuum ovens (gas pressure in oven is at 15Pa) for 8 hours, take it out and re-grind in an agate mortar for 20 minutes, the ground powder is heated to 610°C at a rate of 20°C / min in an air atmosphere and then cooled with the furnace for 7 hours; The powder was ground again in an agate mortar for 20 minutes, and the ground powder was heated to 1310°C in a platinum crucible in an air atmosphere at a rate of 10°C / min and kept for 38 hours, then taken out of the furnace and cooled rapidly; the cooled The material was pulverized and ground for 40 minutes in the mill, soaked in 0.2M sodium hydroxide solution for 10 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com