B<3+> and Al<3+> ion collaboratively doped K6Si2O7 potassium fast ion conductor and preparation method thereof

A technology of ion conductors and ions, which is applied in the field of manufacturing solid potassium fast ion conductors, to achieve the effects of reducing grain boundary gaps, improving potassium ion conductivity, and reducing migration activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

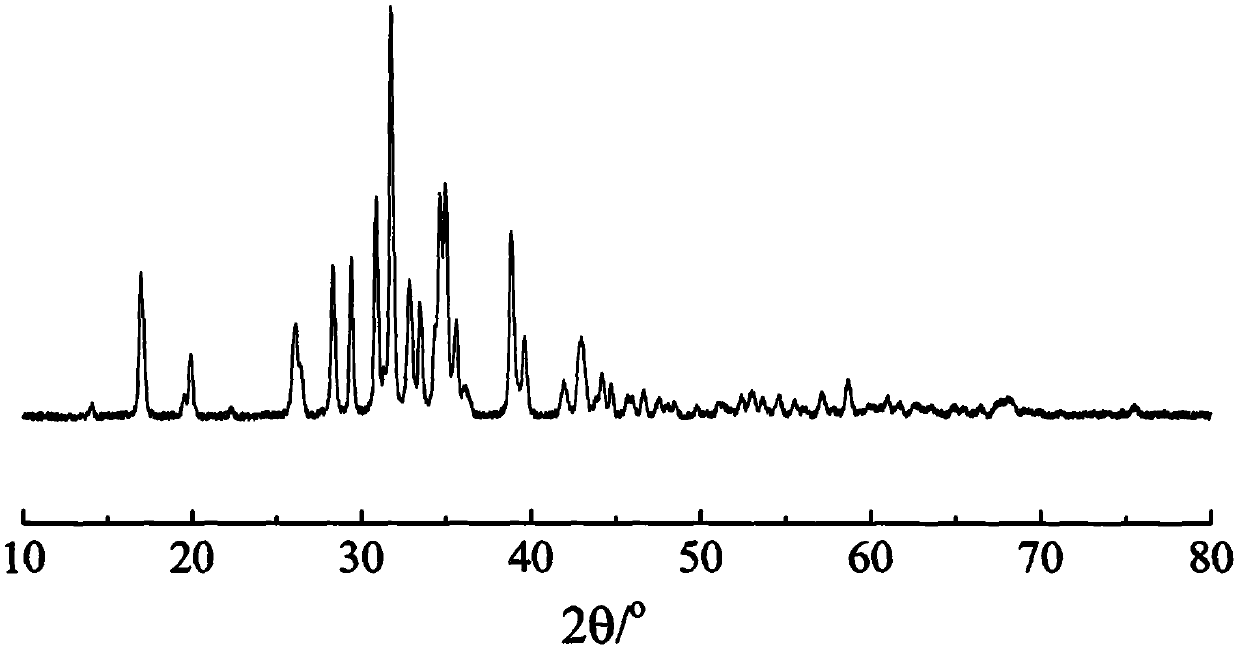

[0011] Example 1: K 2 CO 3 :Al 2 o 3 : SiO 2 :B 2 o 3 According to K 6.1 B 0.05 Al 0.05 Si 1.9 o 7 The ratio of the stoichiometric molar ratio is evenly mixed, adding quality is the dehydrated alcohol of 4% of mixture quality, ball milling 15 hours with the rotating speed of 120 rev / mins in ball mill, after ball milling finishes, in 70 ℃ of vacuum ovens (gas pressure in oven is at 5Pa) for 2 hours, take it out and re-grind it in an agate mortar for 10 minutes, heat up the ground powder to 460°C in an air atmosphere at a rate of 7°C / min and keep it warm for 3 hours, then cool it in the furnace; The powder was ground again in an agate mortar for 10 minutes, and the ground powder was heated up to 750°C at a rate of 5°C / min in an air atmosphere for 10 hours and then cooled with the furnace; after grinding, it was oxidized in 0.1M hydrogen After soaking in sodium solution for 5 minutes, filter, dry and press in 1×10 7 Pressed into thin slices under the pressure of Pa, p...

Embodiment 2

[0012] Example 2: K 2 CO 3 :Al 2 o 3 : SiO 2 :B 2 o 3 According to K 6.2 B 0.1 Al 0.1 Si 1.8 o 7 The ratio of the stoichiometric molar ratio is uniformly mixed, adding quality is the dehydrated alcohol of mixture quality 9%, in ball mill with the rotating speed ball mill of 500 rev / mins 50 hours, after ball mill finishes, in 110 ℃ of vacuum ovens (gas pressure in the oven is at 20Pa) for 9 hours, take it out and re-grind in an agate mortar for 30 minutes, the ground powder is heated to 550°C at a rate of 30°C / min in an air atmosphere and then cooled with the furnace for 10 hours; The powder was ground again in an agate mortar for 30 minutes, and the ground powder was heated to 845 °C at a rate of 15 °C / min in the air atmosphere for 19 hours and then cooled with the furnace; after grinding, it was oxidized in 0.3M hydrogen After soaking in sodium solution for 12 minutes, filter, dry and press in a 7×10 7 Press it into thin slices under the pressure of P, put the pre...

Embodiment 3

[0013] Example 3: K 2 CO 3 :Al 2 o 3 : SiO 2 :B 2 o 3 According to K 6.15 B 0.07 Al 0.08 Si 1.85 o 7 The ratio of the stoichiometric molar ratio is evenly mixed, adding quality is the dehydrated alcohol of mixture quality 5%, in ball mill with the rotating speed ball mill of 300 rev / mins 30 hours, after ball mill finishes, in 80 ℃ of vacuum ovens (gas pressure in oven is at 15Pa) for 7 hours, take it out and re-grind in an agate mortar for 20 minutes, and the ground powder is heated to 500°C at a rate of 20°C / min in an air atmosphere and then cooled with the furnace for 7 hours; The powder was ground again in an agate mortar for 20 minutes, and the ground powder was heated to 800°C at a rate of 10°C / min in the air atmosphere and kept for 15 hours, then cooled with the furnace; after grinding, it was oxidized in 0.2M hydrogen After soaking in sodium solution for 10 minutes, filter, dry and place in a press at 5×10 7 Pressed into thin slices under the pressure of P, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com