Preparation method of allopurinol crystal

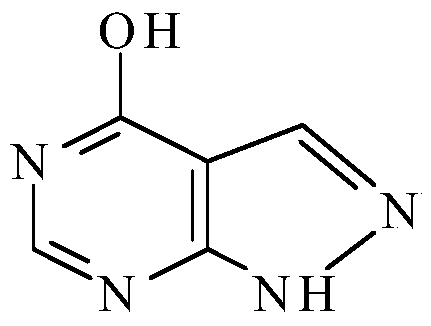

A technology of allopurinol and crystals, which is applied in the field of preparation of allopurinol crystals, can solve the problems of increasing production safety risks, increasing the pressure of sewage treatment, etc., and achieves the effects of high purity, environmentally friendly auxiliary materials, and simple operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

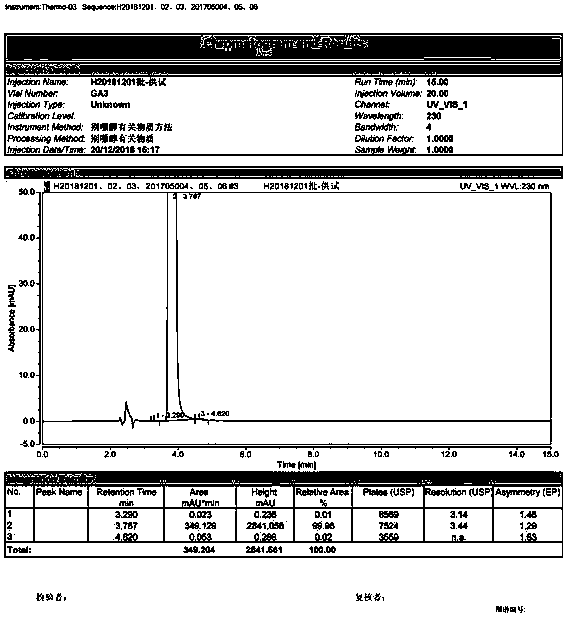

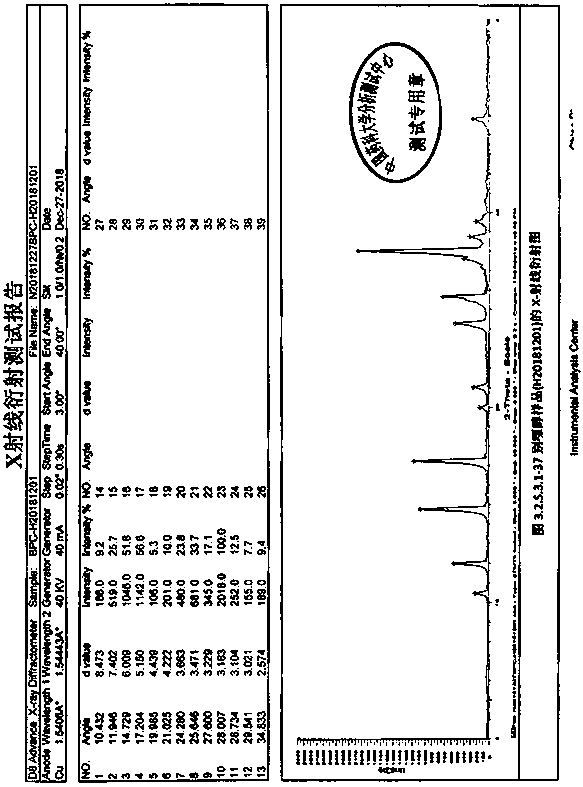

Embodiment 1

[0016] Add 18.0Kg of crude allopurinol to 1080L of purified water, heat to 99°C, stir to dissolve, then add 0.9kg of activated carbon, heat and stir for 30 minutes, then press filter while hot, cool to 20°C, centrifugal filter, wash with 36L of pure water, The solid was dried in a hot air circulation oven at 100° C. for 12 hours to obtain 12.3 kg of allopurinol finished product.

Embodiment 2

[0018] Add 19.6.0Kg of crude allopurinol to 1960L of purified water, heat to 90°C, stir to dissolve, then add 1.9kg of activated carbon, heat and stir for 60 minutes, press filter while hot, cool to 25°C, centrifugal filter, wash with 60L of pure water , the solid was placed in a hot air circulation oven at 105°C and dried for 10 hours to obtain 13.8Kg of allopurinol finished product.

Embodiment 3

[0020] Add 20.5Kg of allopurinol crude product into 1600L of purified water, heat to 95°C, stir to dissolve, then add 1.6kg of activated carbon, heat and stir for 30 minutes, press filter while hot, cool to 30°C, centrifugal filter, wash with 60L of pure water, The solid was dried in a hot air circulation oven at 110° C. for 8 hours to obtain 14.8 Kg of allopurinol finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com