Reinforcing canvas for impact-resistant conveyor belt and preparation method of reinforcing canvas

A conveyor belt and impact-resistant technology, applied in the field of reinforced canvas and its preparation, can solve the problems of damage to the skeleton material of the conveyor belt, the rupture of the rubber of the conveyor belt, and the shortening of the service life of the conveyor belt, so as to reduce the pressure and prolong the service life. , the effect of reducing the maximum stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

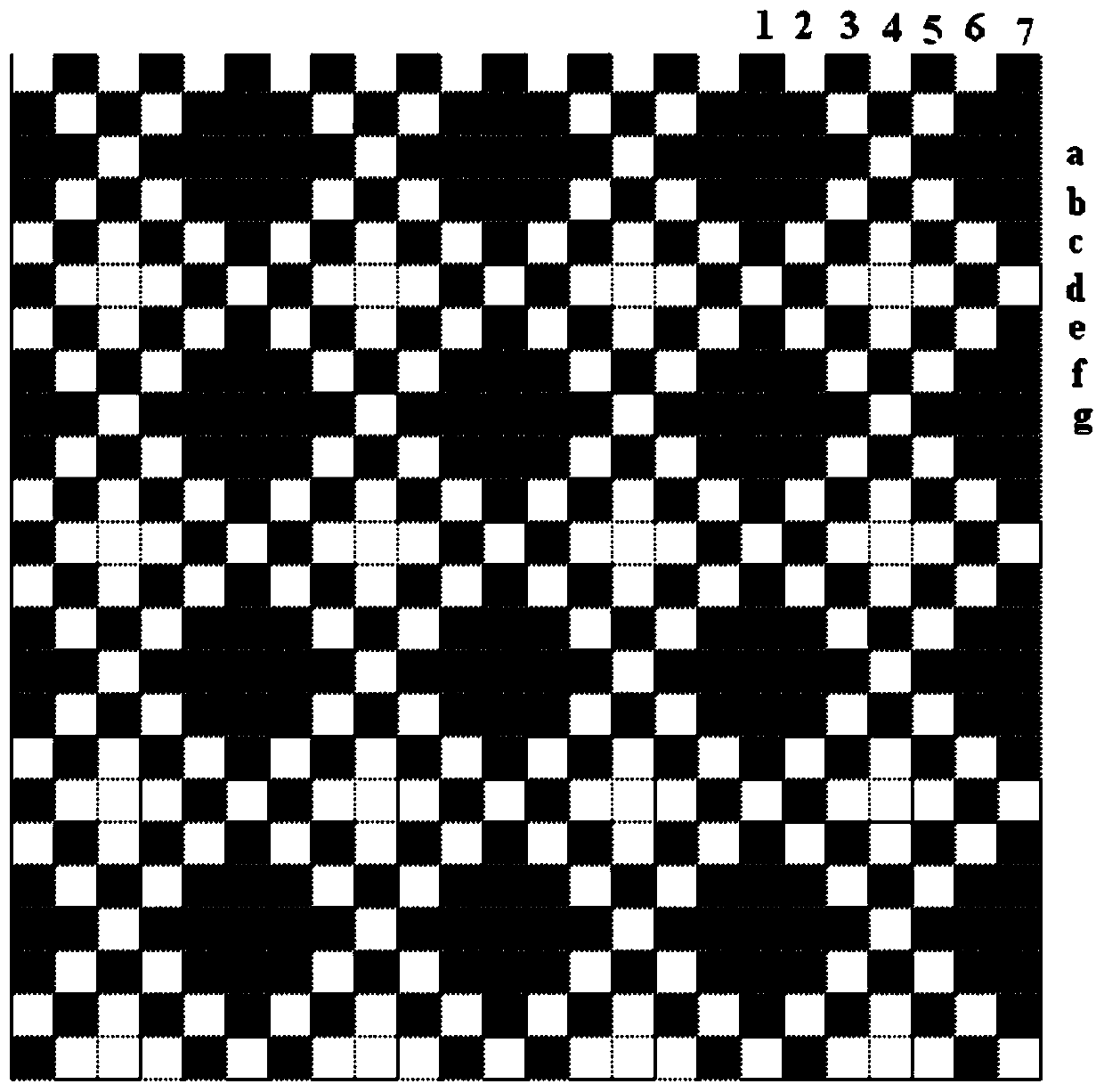

[0025] Such as figure 1 As shown, a reinforced canvas for impact-resistant conveyor belts, the reinforced canvas is composed of several cyclic honeycomb unit structures, each unit structure includes several groups of warp and weft structures, and is formed by interweaving the warp and weft; The warp yarns include the first warp yarn a, the second warp yarn b, the third warp yarn c, the fourth warp yarn d, the fifth warp yarn e, the sixth warp yarn f and the seventh warp yarn g; the weft yarns include the first weft yarn 1, the second warp yarn Weft yarn 2, third weft yarn 3, fourth weft yarn 4, fifth weft yarn 5, sixth weft yarn 6 and seventh weft yarn 7.

[0026] The first warp yarn a is located above the first weft yarn 1, the second weft yarn 2, the third weft yarn 3, the fifth weft yarn 5, the sixth weft yarn 6 and the seventh weft yarn 7, and below the fourth weft yarn 4;

[0027] The second warp yarn b is located above the first weft yarn 1, the second weft yarn 2, the ...

Embodiment 2

[0036] Raw material: 1400dtex nylon 66 industrial filament, manufactured by Henan Shenma Group.

[0037] (1) Weaving: Twisting the above-mentioned nylon 66 industrial filaments, and then sending them through warping or creels, and weaving them into a canvas primary product including several honeycomb unit structures;

[0038] Warp yarn: 2 shares of 1400dtex nylon 66 industrial filaments are twisted after plying on a ring twisting machine. The twisting machine is R814 of Yichang Textile Machinery, the twisting degree is 120 twists / m, and the twisting direction is Z.

[0039] Weft yarn: Twist 3 shares of 1400dtex nylon 66 industrial filament on a ring twisting machine, the twisting machine is R814 of Yichang Textile Machinery, the twisting degree is 120 twists / m, and the twisting direction is Z;

[0040] Weaving: Creel let-off is adopted, warp yarns are placed on custom-made creels, warp let-off system outside the machine is adopted, Picanol OPTIMAX flexible rapier loom is used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com