On-line measuring device and on-line measuring method of gas partial pressure

A measuring device and gas partial pressure technology, applied in the field of measurement, can solve the problems of insufficient sensitivity and inaccurate measurement results, and achieve the effect of ensuring accuracy, avoiding cross-contamination, and ensuring regular calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]The following exemplary embodiments of the present disclosure will be described in more detail with reference to Examples. While the exemplary embodiment shows an exemplary embodiment of the present disclosure in the specification, it should be understood that the present disclosure may be implemented and should not be limited to the embodiments set forth herein in various forms. Rather, these embodiments are able to more thorough understanding of the present disclosure, and the scope of the present disclosure can be completely conveying to those skilled in the art.

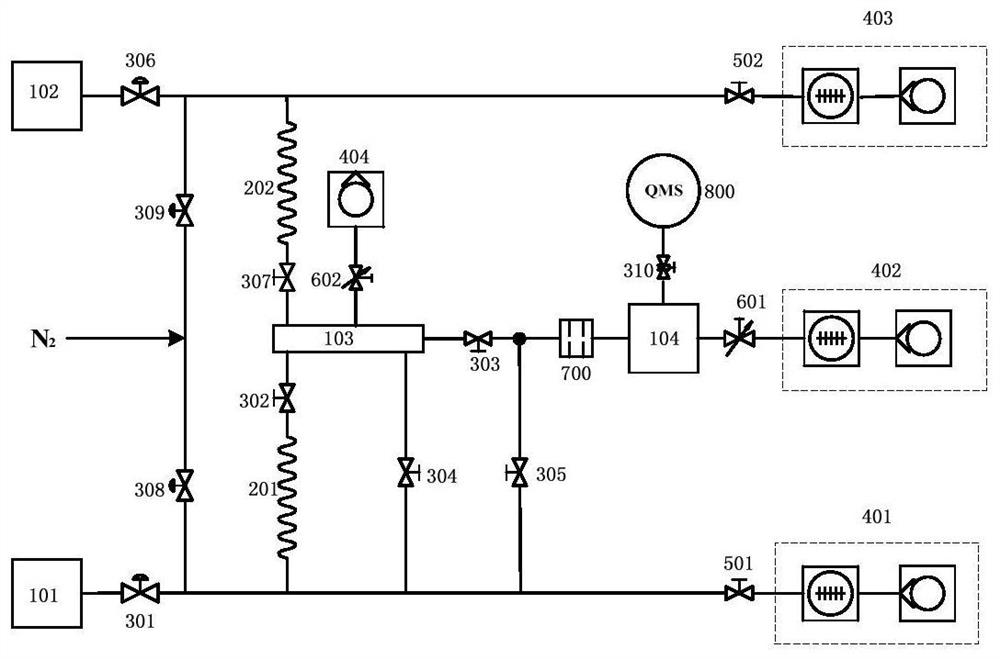

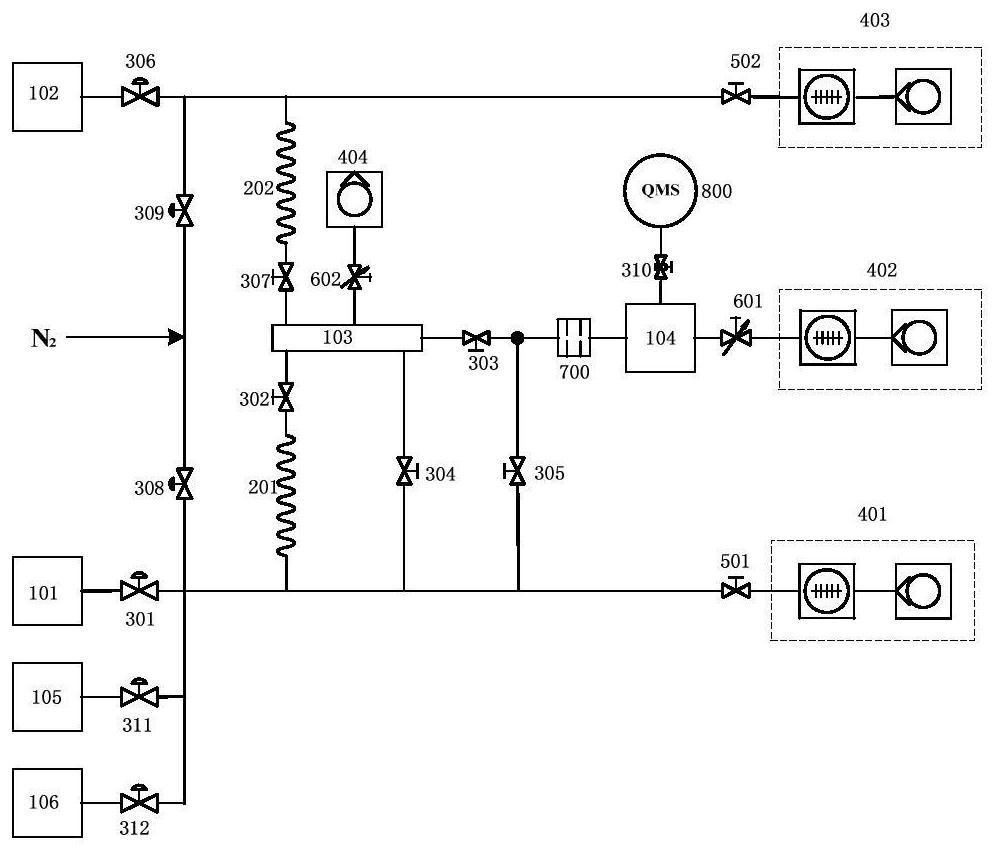

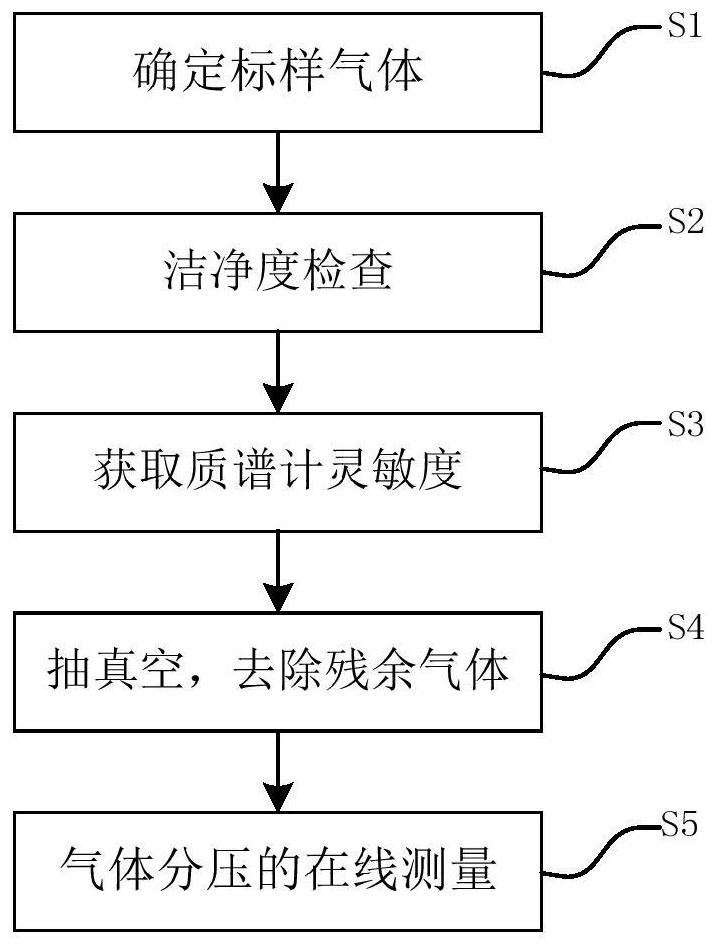

[0043] like figure 1 , The present invention provides online measurement and calibration apparatus of the partial pressure of a gas, the apparatus comprising a vacuum chamber into the loading channel, channel nitrogen, suction pump, mass spectral analysis module, a control valve assembly and data acquisition module. Wherein the vacuum chamber includes 4, respectively measured gas source chamber 101, the calibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com