Partial discharge detecting sensor and manufacturing method thereof

A technology of partial discharge detection and manufacturing method, which is applied in the direction of instruments, measuring electricity, measuring devices, etc., can solve the problems of difficult production, high production and use costs, and difficulty in mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

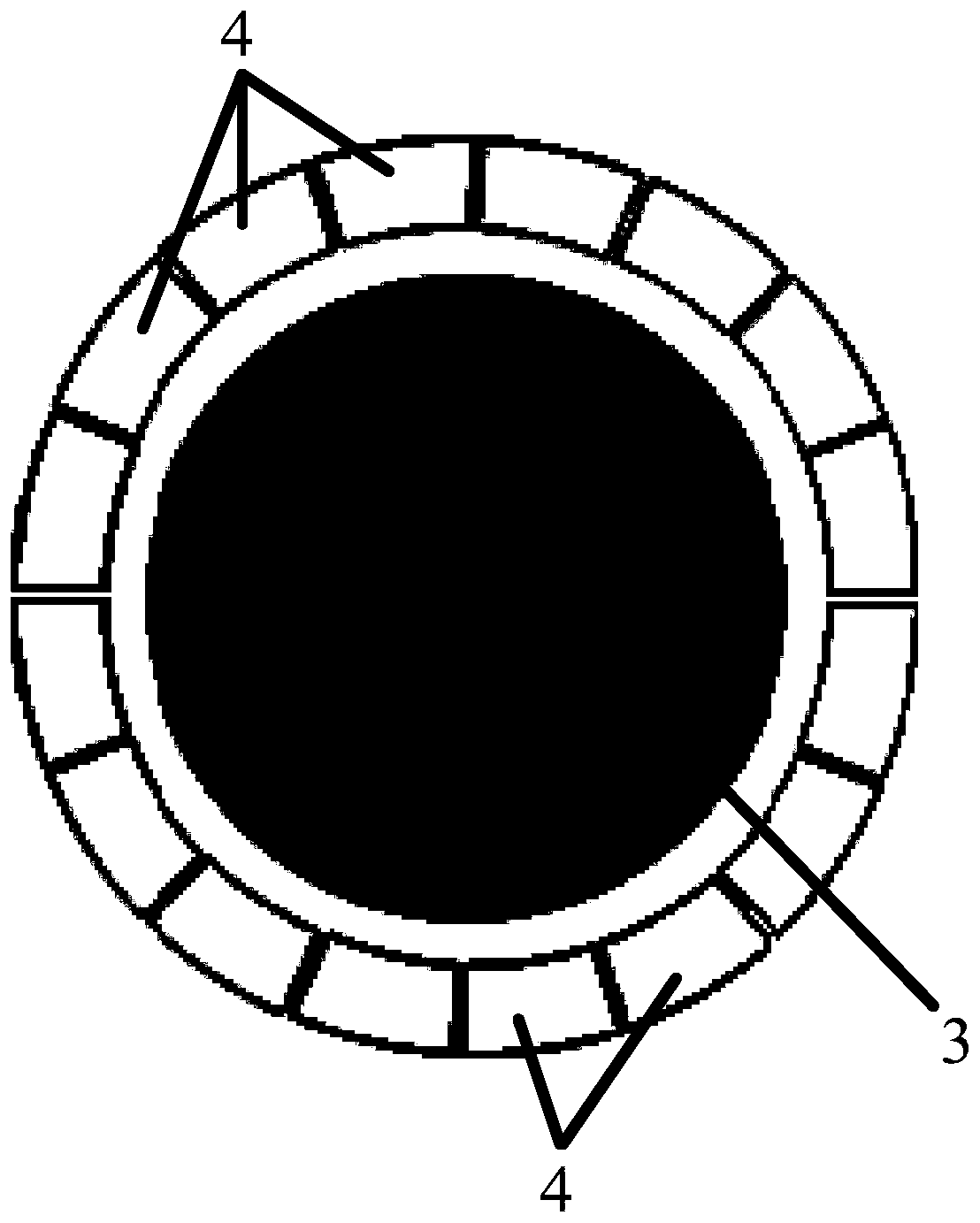

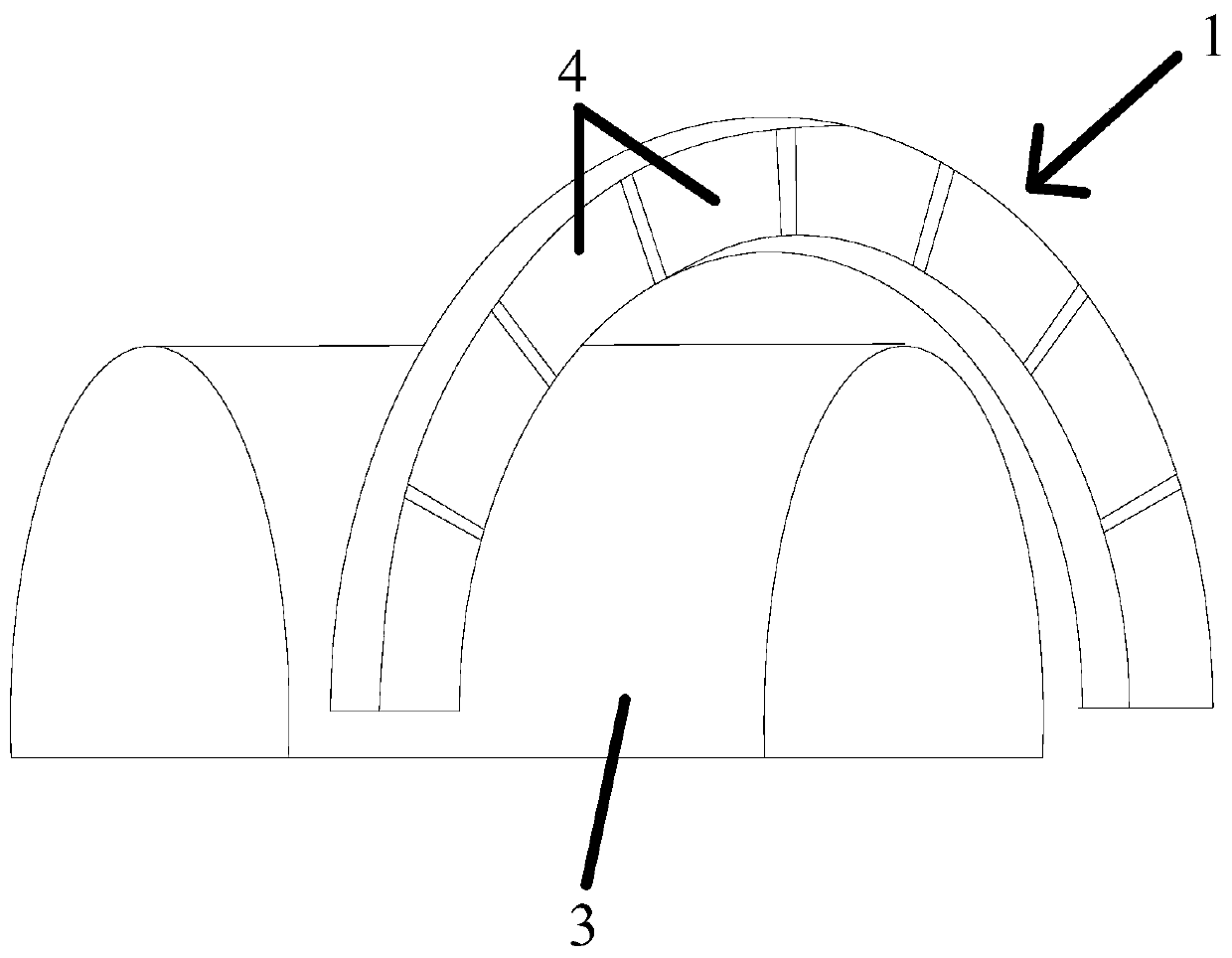

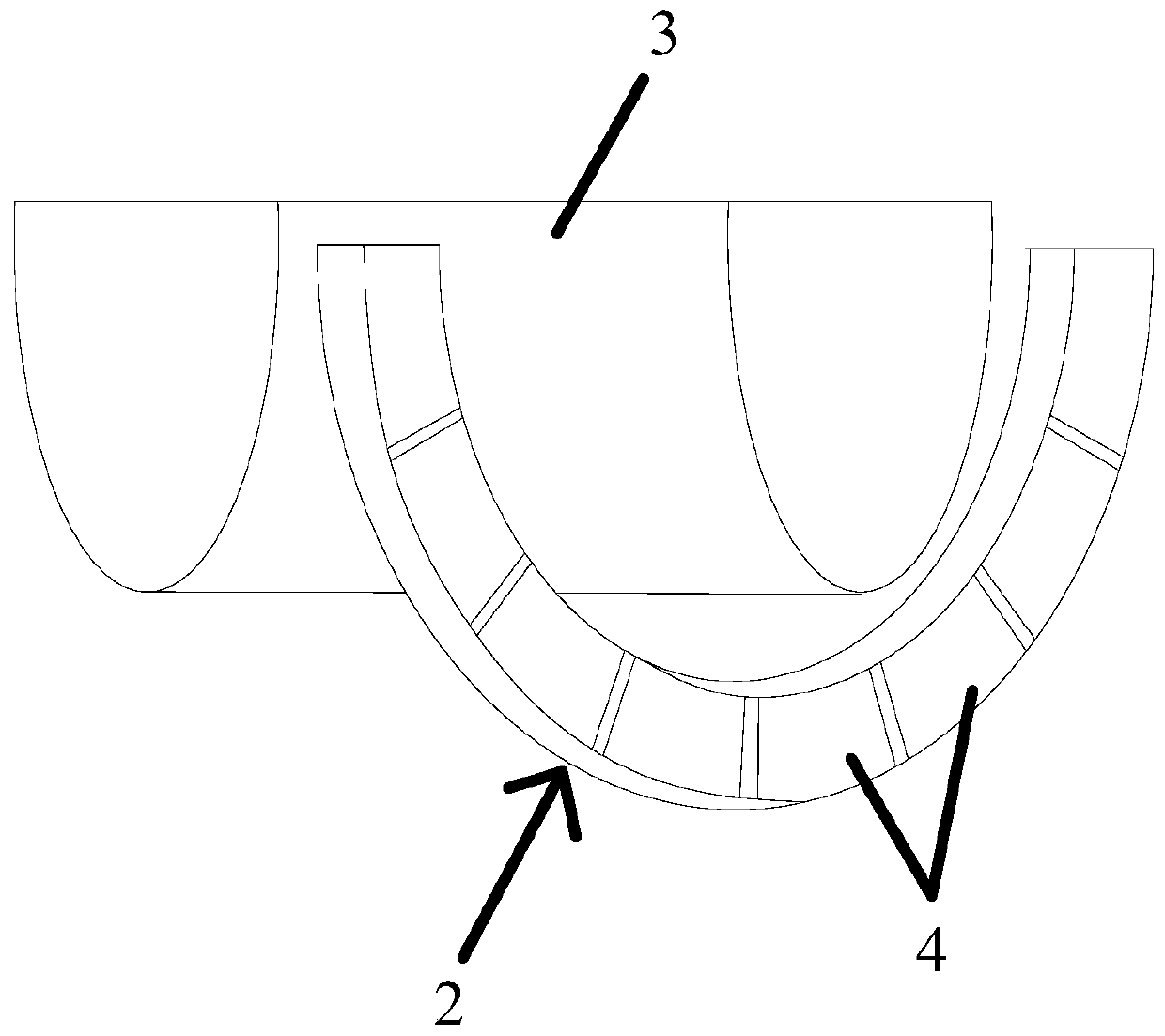

[0045] This embodiment provides a partial discharge detection sensor, the detection range of which is 3MHz to 36MHz, the partial discharge detection sensor such as Figure 1 to Figure 3 shown, which includes:

[0046] The first half-ring magnetic core piece 1 is composed of 8 magnetic core blocks 4, and the adjacent magnetic core blocks 4 are fixed together by epoxy resin adhesive;

[0047] The second half-ring magnetic core part 2 is arranged corresponding to the first half-ring magnetic core part 1, and the second half-ring magnetic core part 2 is composed of 8 magnetic core blocks 4 to form the first half-ring magnetic core part 1 Its size and shape are all the same as each magnetic core block 4 of the second half-ring magnetic core part 2, and the adjacent magnetic core blocks 4 are fixed together by epoxy resin adhesive; the above-mentioned first half-ring magnetic The core piece 1 and the second half-ring magnetic core piece 2 form an annular magnetic ring with an inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com