Method for manufacturing semiconductor three-dimensional Hall sensor suitable for high-temperature working environment

A Hall sensor, working environment technology, applied in the direction of instruments, single equipment manufacturing, measuring devices, etc., can solve the problems of the multi-dimensional Hall sensor system is bulky, complex chip layout, unable to work normally, etc., to improve the measurement sensitivity, volume Small, good chemical stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

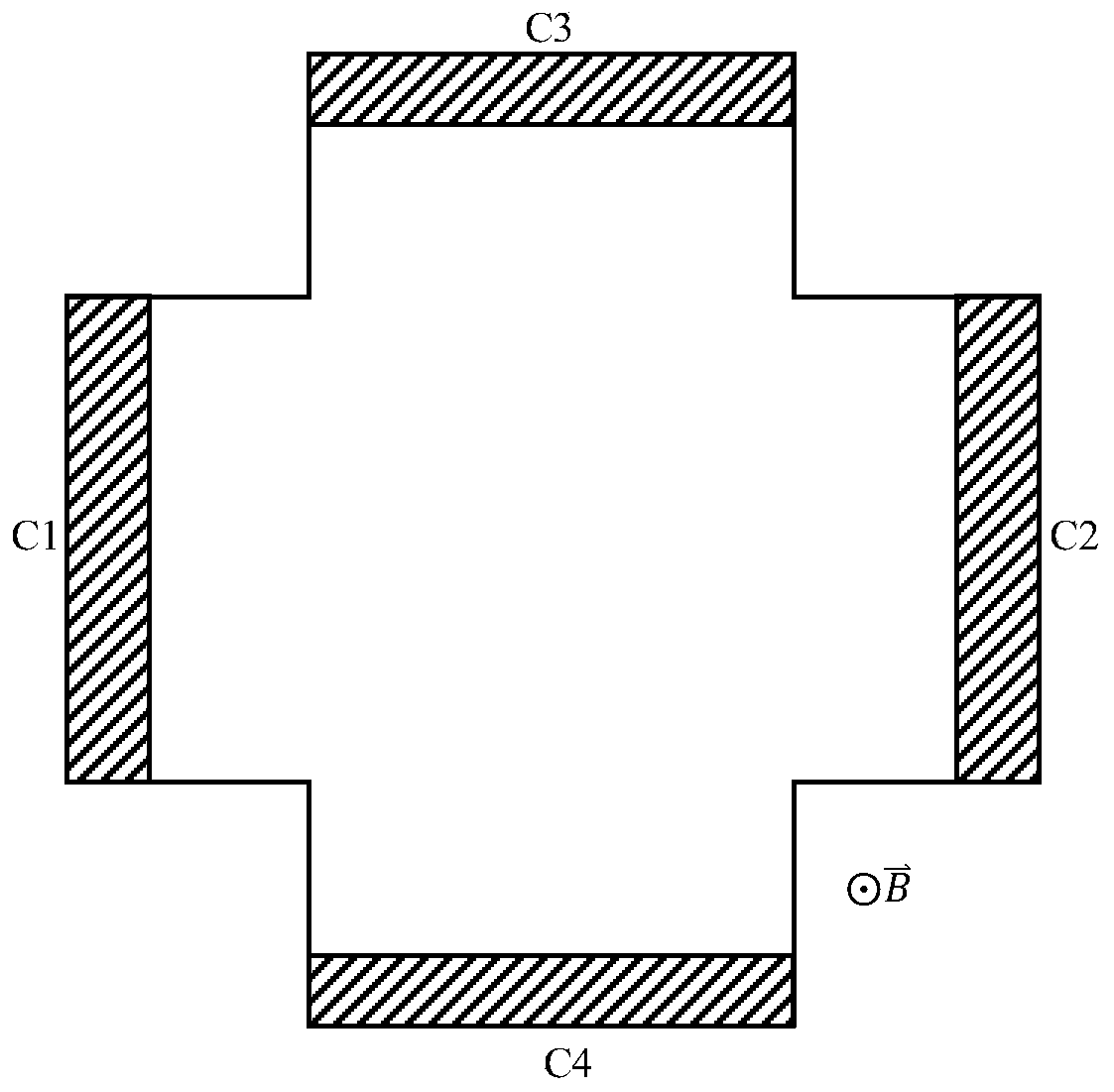

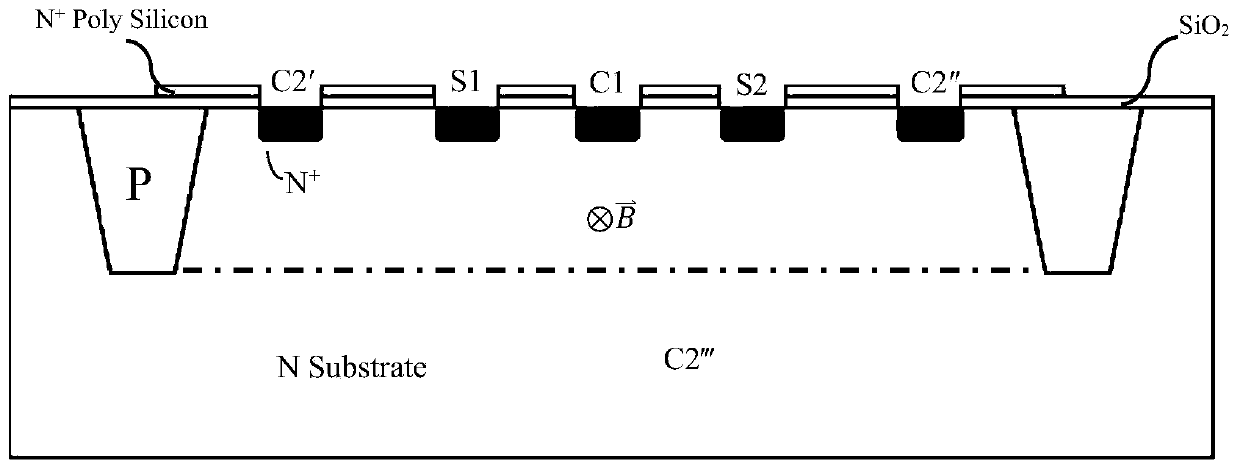

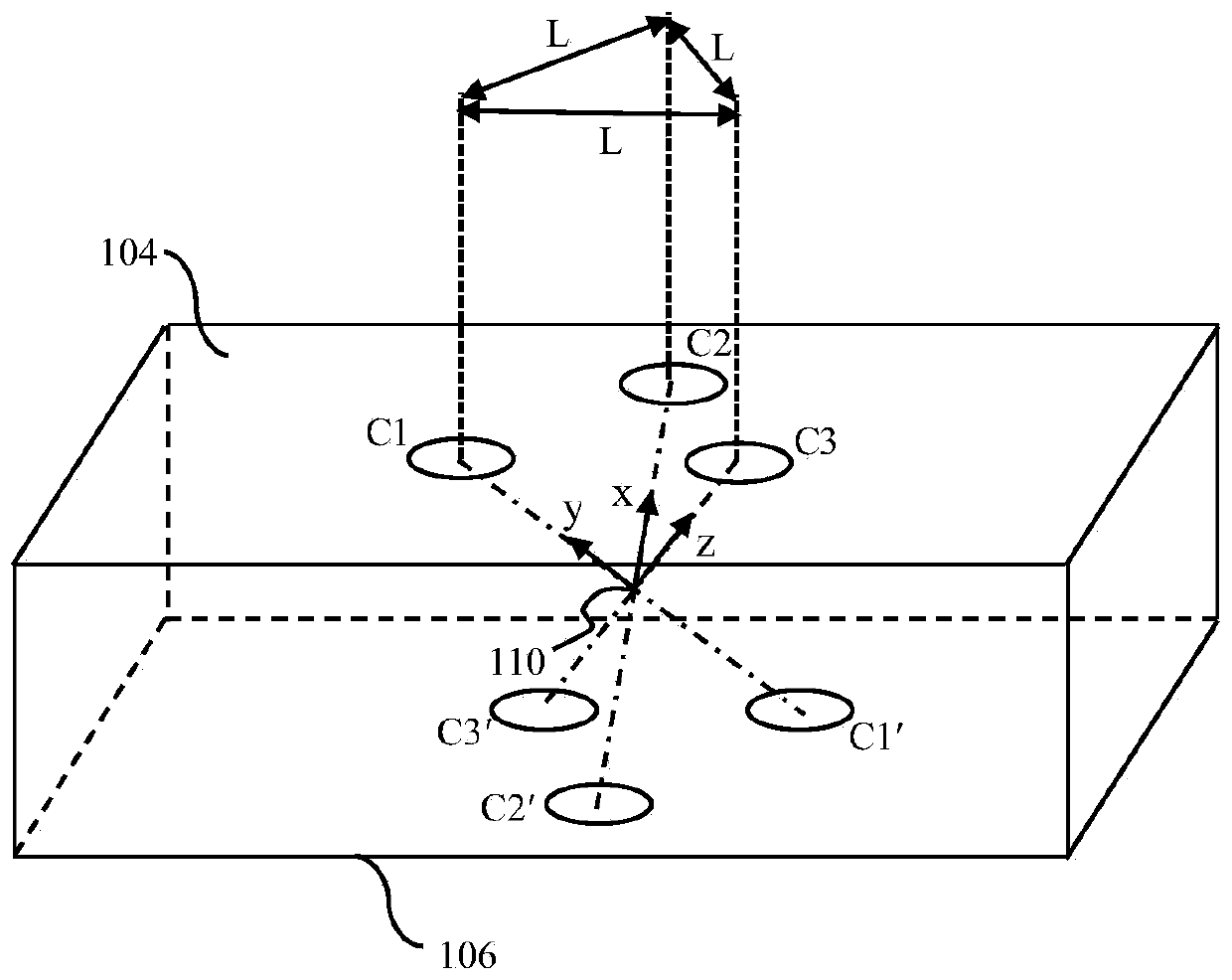

[0045] Such as Figure 4 As shown, wide bandgap semiconductor materials such as SiC or GaN are used, and 5 main electrodes and 8 Hall sensing electrodes are designed and fabricated on the surface of the material, and the metal / semiconductor contact type is ohmic contact. Among them, the 5 main electrodes are 1 central current inflow electrode (B) and 4 current outflow electrodes (B X1 , B X2 , B Z1 and B Z2 ), the 8 Hall sensing electrodes are X 1 ~X 4 and Z 1 ~ Z 4 , where two pairs of Hall sensing electrodes X 1 、X 2 and x 3 、X 4 Measure two magnetic field components in space (X and Z directions), and the remaining four Hall sensing electrodes Z 1 ~ Z 4 Measure the third magnetic field component (Y direction).

[0046] Using insulating layers ①, ②, ③ and ④ embedded between the Hall sensing electrodes, the insulating layer material can be SiO 2 、Si 3 N 4 、Al 2 o 3 etc., using this technology can effectively guide the sensing current direction while significa...

Embodiment 2

[0066] In this embodiment, the intrinsic GaN material is used, and the background carrier concentration of the material is 5×10 15 cm -3 , the insulating layer material used is Si 3 N 4 . The three main electrodes B and B of the device chip X1 , B X2 The size is 40μm×10μm, and the remaining two main electrodes B Z1 , B Z2 The size is 10μm×10μm, Hall sensing electrode Z 1 ~ Z 4 、X 1 ~X 4 The size is 10μm×10μm, the size of each embedded isolation insulating layer is 40μm×60μm, and the Hall sensing electrode X 1 、X 2 The distance between the center and the center of the center main electrode B is 45 μm, and the Hall sensing electrode X 3 、X 4 The distance between the center and the center of the center main electrode B is 30 μm, and the main electrode B Z1 , B Z2 The distance between the center and the center of the center main electrode B is 75 μm, and the main electrode B X1 , B X2 The distance between the center and the center of the center main electrode B is...

Embodiment 3

[0074] As a separate embodiment or as a supplement to Embodiment 1, the central current flowing into the electrode B adopts a circular or rectangular shape; the current flowing out of the electrode B X1 , B X2 , B Z1 , B Z2 Rectangular shape is preferred for the eight Hall sensing electrodes, and circular shape can also be used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com