Position Estimation and Compensation Method of Vector Control Based on Hall Position Sensor

A Hall position and compensation method technology, applied in the direction of torque ripple control, electronic commutator, etc., can solve problems such as installation accuracy errors, achieve the effects of compensating for installation position deviation, compensating for position angle distortion, and reducing waveform distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

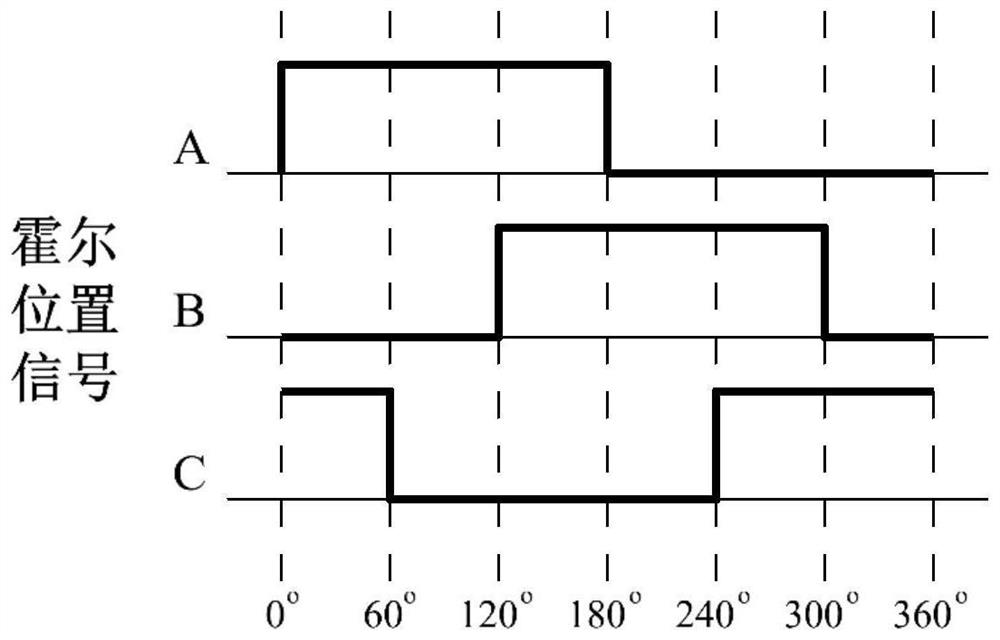

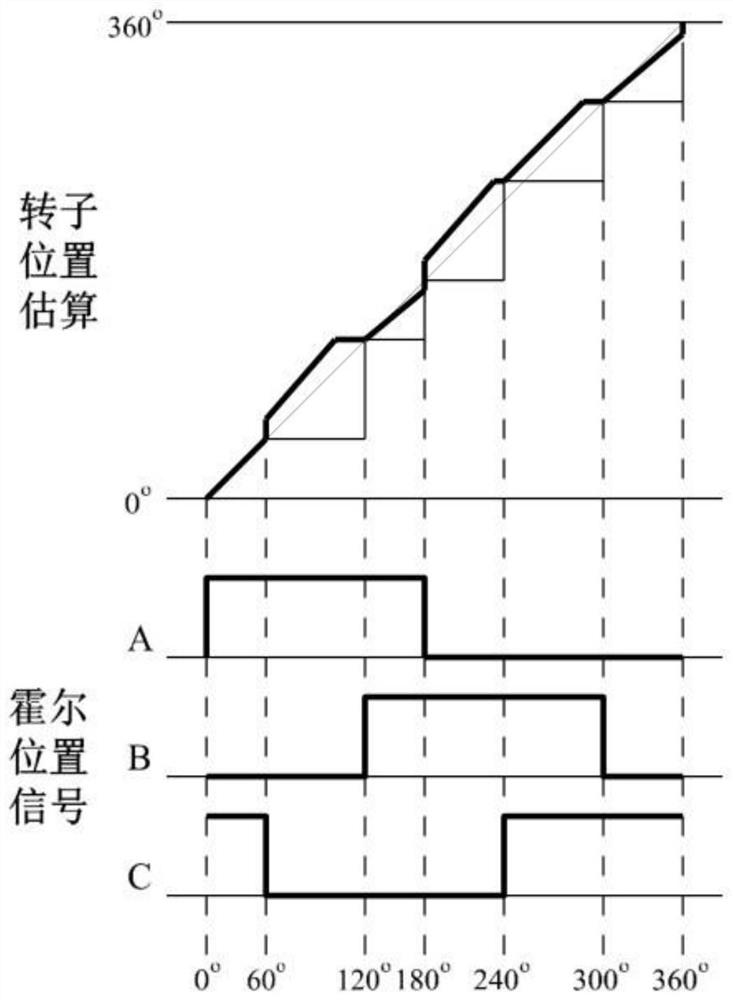

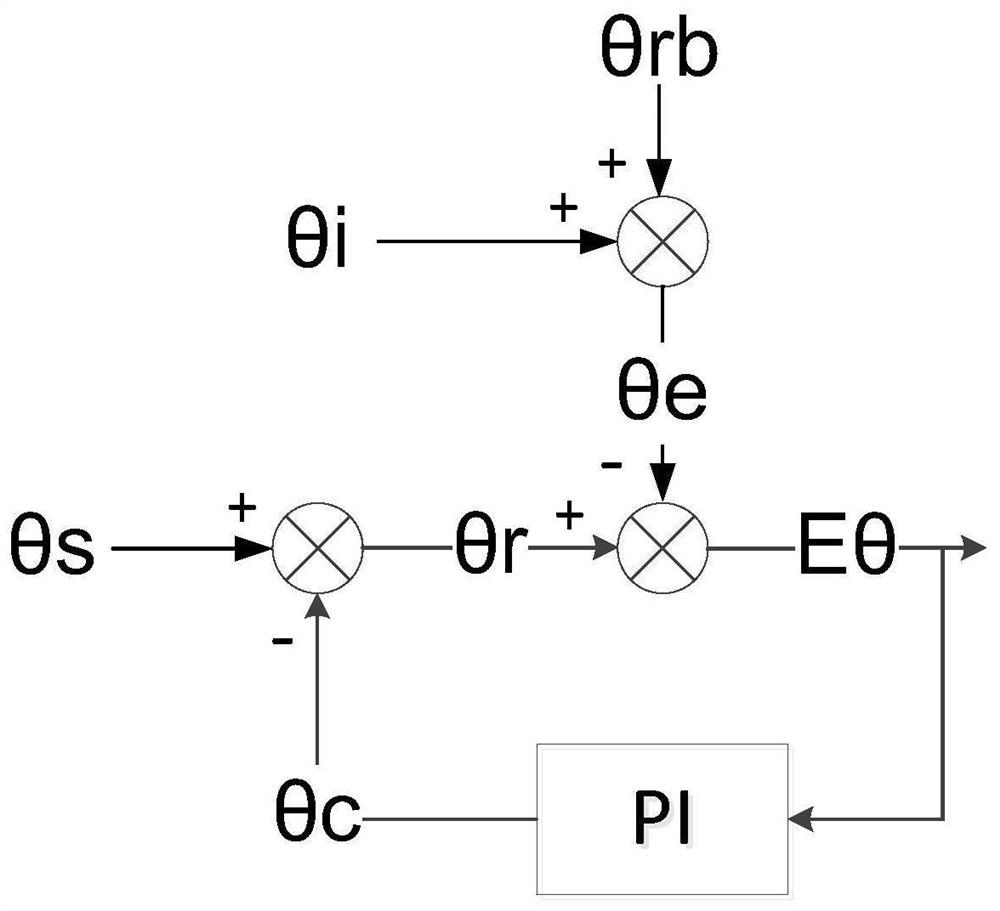

[0060] When the second jump edge is detected, according to the state change of the Hall sensor, it is judged that the motor is rotating forward, and the corresponding rotor angle θr=θs is 0°. Set the current position as the initial angle θrb of the first sector, and the initial angle is 0°. And the time interval between two jump edges is T, then when running in the first sector for t time, the estimated rotor angle θe=θrb+θi, that is, θe=0°+60*t / T.

[0061] When the third jump edge is detected, enter the second sector. According to the Hall state, the uncompensated installation angle θs=60° and the compensation value θc=0° of the second sector are obtained, then θr=θs-θc= 60°. And the total running time of the first sector is 0.9T, the estimated value of the initial angle of the second sector is θe=0°+60*0.9T / T=54°, then Eθ=θr-θe=6°. Assuming Ki=0.1, then θc=θc+Eθ*Ki=0.6°, then θs will also be used as the initial angle θb of the current sector at this time, that is, θb=60°. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com