CC pin circuit of USB Type-C

A circuit and pin technology, which is applied in the field of CC pin circuit of USB Type-C, can solve the problems of inability to activate and realize CC connection, and achieve the effect of realizing high voltage protection and solving the problem of withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

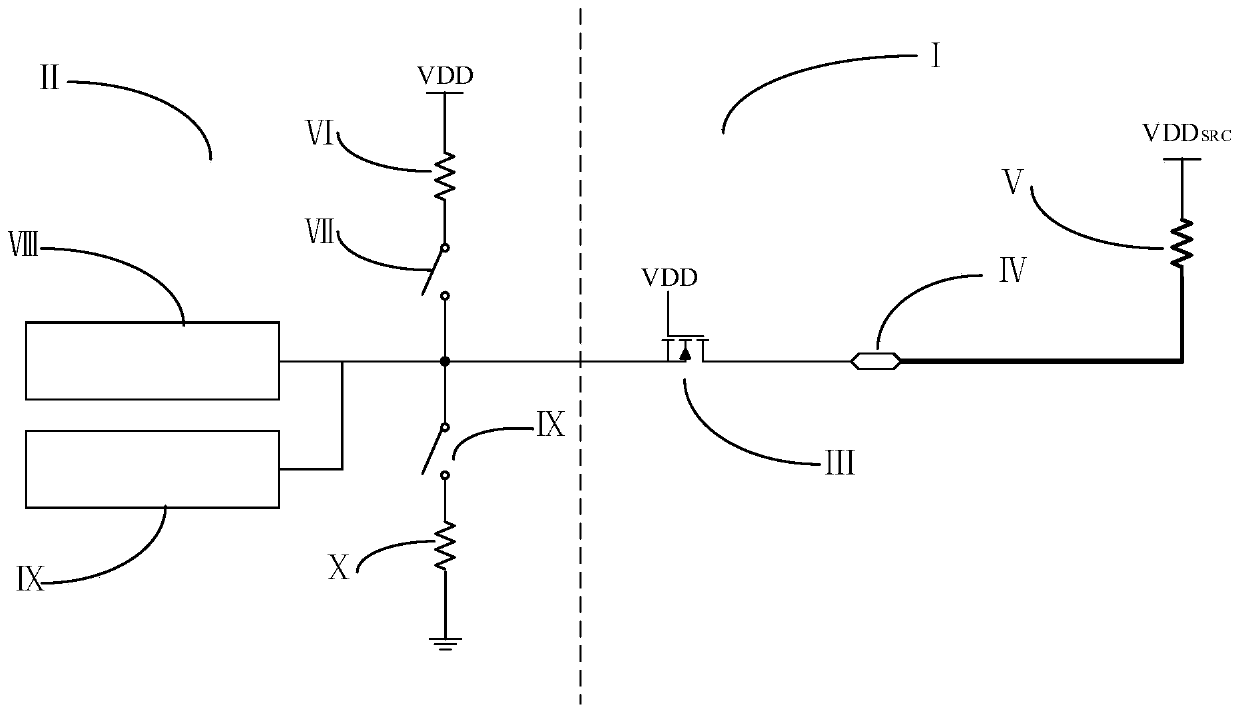

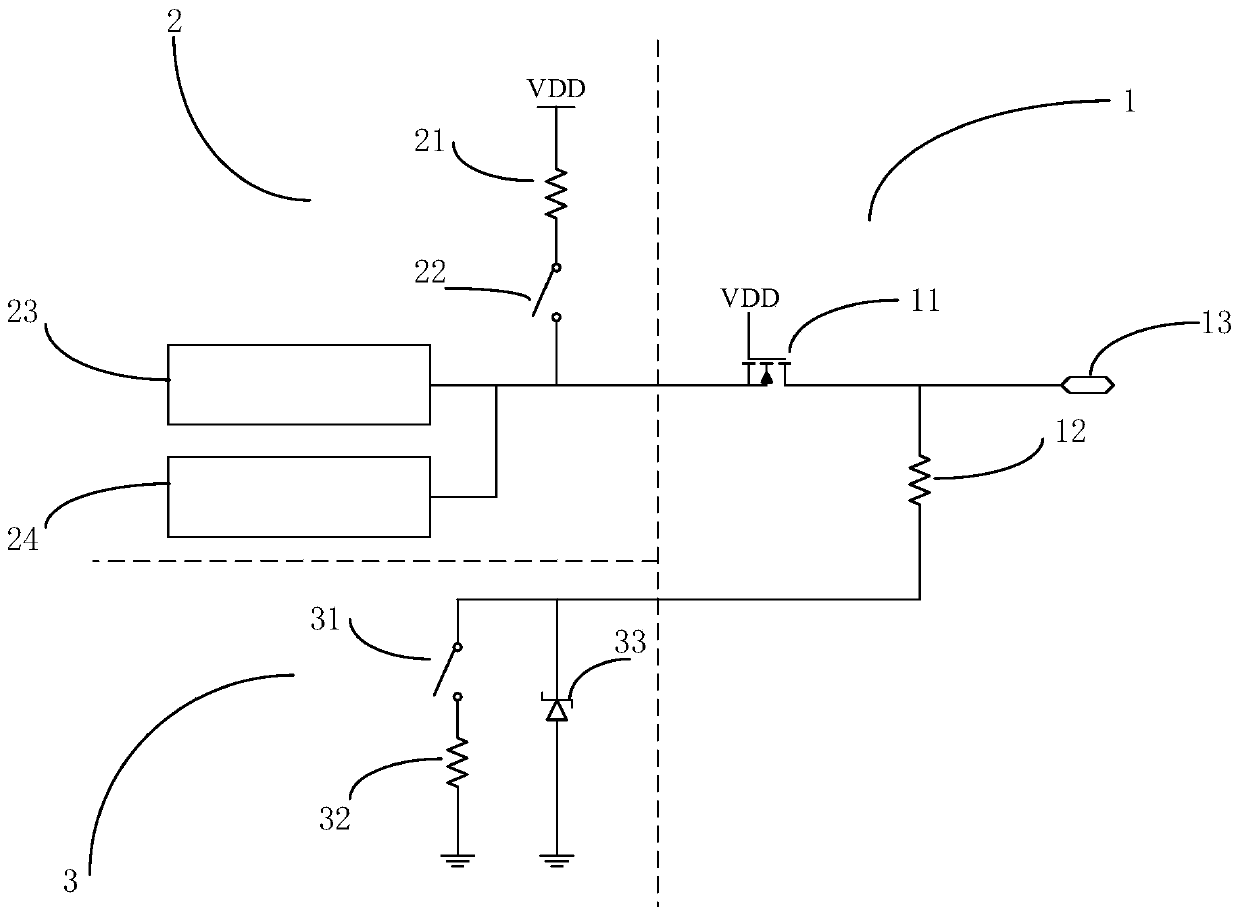

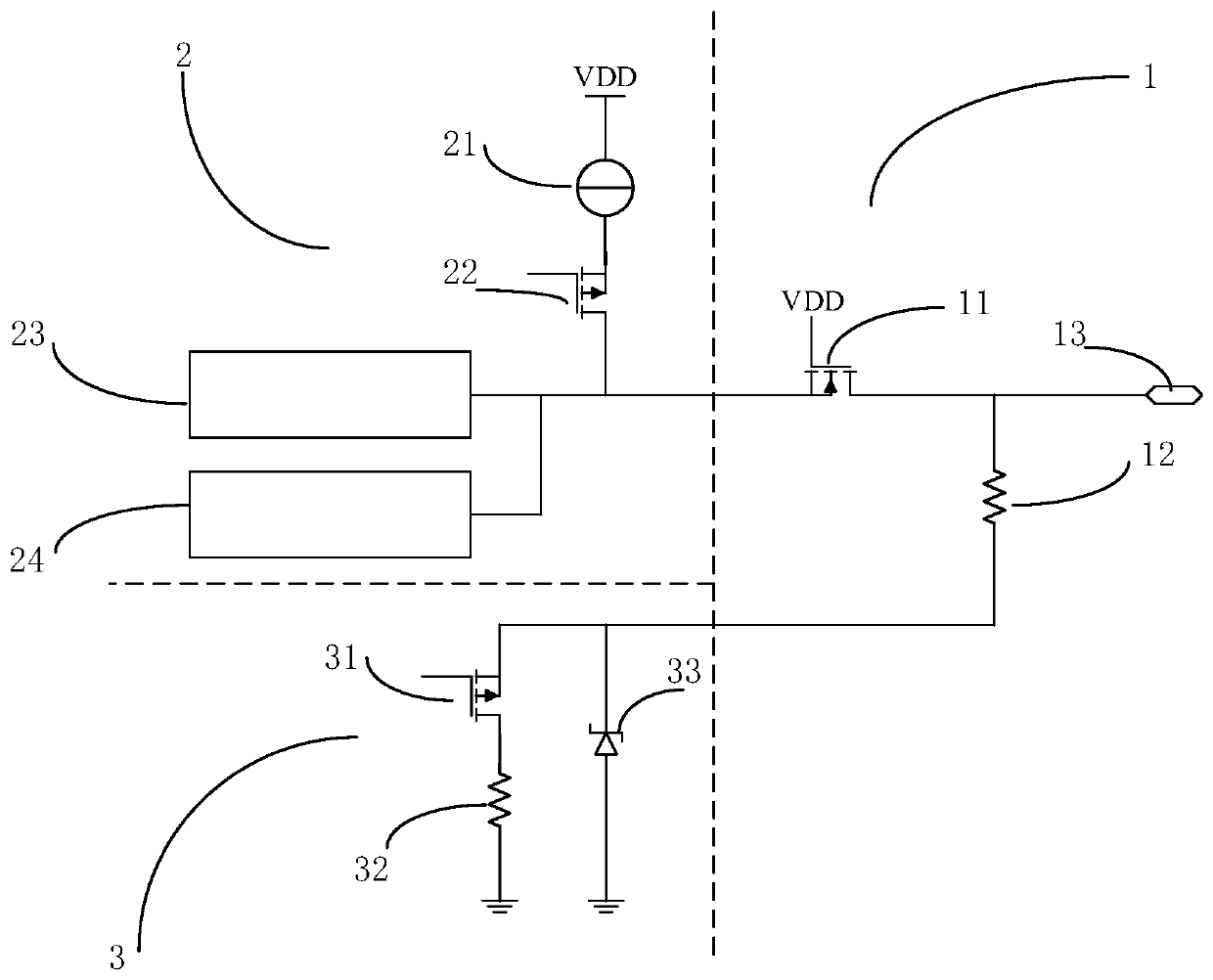

[0026] see figure 2 , figure 2 It is a schematic diagram of the CC pin circuit structure of USB Type-C in the present invention. The CC pin circuit includes a high-voltage NMOS11, a pull-up resistor circuit, a CC connection detection circuit 23, a PD communication circuit 24, a pull-down resistor circuit, and a voltage clamping circuit. The gate of the high-voltage NMOS11 is connected to the internal power supply VDD, and the pull-up resistor circuit, CC One end of the connection detection circuit 23 and the PD communication circuit 24 are both connected to the source of the high-voltage NMOS, the drain of the high-voltage NMOS11 is connected to the pull-down resistor circuit, and the drain of the high-voltage NMOS11 is connected to the first end of the CC pin, and the pull-down resistor circuit includes The first resistance circuit and the second resistance circuit, and the voltage clamping circuit are connected between the series node of the first resistance circuit and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com