Binocular camera device with front light splitting structure

A technology of binocular camera and beam splitting device, which is applied in the field of cameras, can solve the problem of insufficient back focus space of the lens, and achieve the effects of reducing work links, increasing degrees of freedom, and increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

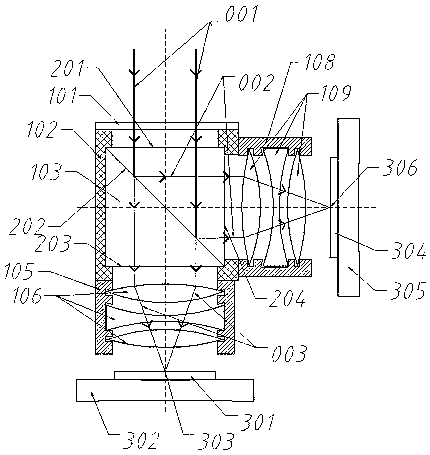

[0024] Example 1 as figure 2 As shown, the rear of the spectroscopic device 103 is provided with a first imaging lens group 106, and its side is provided with a second imaging lens group 109, which are used to focus and project the two beams of sub-rays after the incident light 001 has been split by the spectroscopic device 103 respectively. On the first optical sensor 301 and the second optical sensor 304, the two beams of sub-rays are reflected light and transmitted light respectively.

[0025] The forward light window 101 uses high-transmittance optical glass as the incident light window, and the surface is coated with an anti-reflection film to enhance light transmittance; a high-hardness protective film is coated to prevent scratches on the surface of the lens. The thickness is designed to be 1-3 mm, and the area is guaranteed to completely cover the incident surface 201 of the spectroscopic device 103 . The mechanical housing 102 has a built-in gasket 112, and the mech...

Embodiment 2

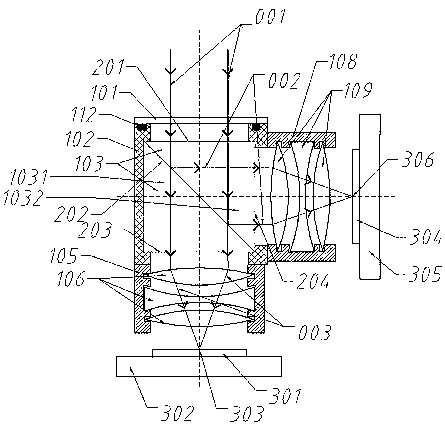

[0030] Example 2 as image 3 As shown, the rear of the spectroscopic device 103 is provided with a first imaging lens group 106 and a second imaging lens group 109, which are used to focus and project the two beams of sub-rays after the incident light 001 is split by the spectroscopic device 103 onto the first optical sensor respectively. 301 and the second optical sensor 304.

[0031] The beam splitting device 103 adopts a broadband non-polarizing cubic beam splitting prism mirror, and its working wavelength is 400nm~1100nm. Its structure is the same as that of Embodiment 1. It is formed by glueing a right-angle sub-prism I1031 and a right-angle sub-prism II1032, and the glued surface 202 is coated with a functional film to realize the light-splitting function. . The incident surface 201, the first exit surface 203, and the second exit surface 204 are the same as in Embodiment 1. Since the reflected light of the film generally produces polarized light, an additionally design...

Embodiment 3

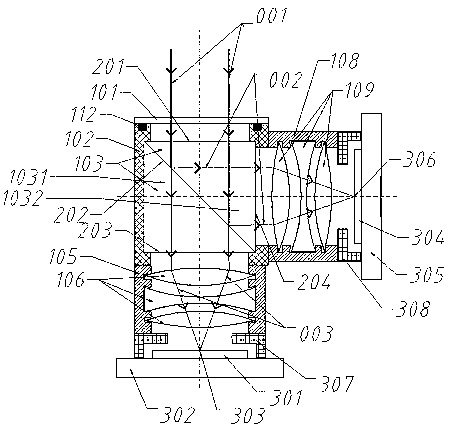

[0035] Embodiment 3 The spectroscopic device 103 includes a spectroscopic prism, and the spectroscopic prism is formed by cementing a triangular sub-prism and an offset sub-prism. A day / night switch is provided between the first imaging lens group 106 , the second imaging lens group 109 , the first optical sensor 301 , and the second optical sensor 304 . The day / night converter includes a long-wave cut filter.

[0036] Considering that light is reflected from the coating surface, linearly polarized light will inevitably be generated, resulting in different polarization components of transmitted light and reflected light. This effect can be reduced by optimizing the film structure, but it cannot be avoided. Sometimes, however, polarized light is useful. Therefore, in this embodiment, the main purpose is to realize polarization and spectroscopic imaging of light.

[0037] like Figure 4 As shown, the overall structural design and composition are similar to those of Example 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com