Vacuum pump and vane parts and rotor for the vacuum pump and fixed vanes

A vacuum pump and vane technology, which is applied to parts, pump elements, pumps, etc. of elastic fluid pumping devices, can solve problems such as flashing, increased processing costs, and increased curvature of convex arc surfaces, so as to prevent backflow , the effect of preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

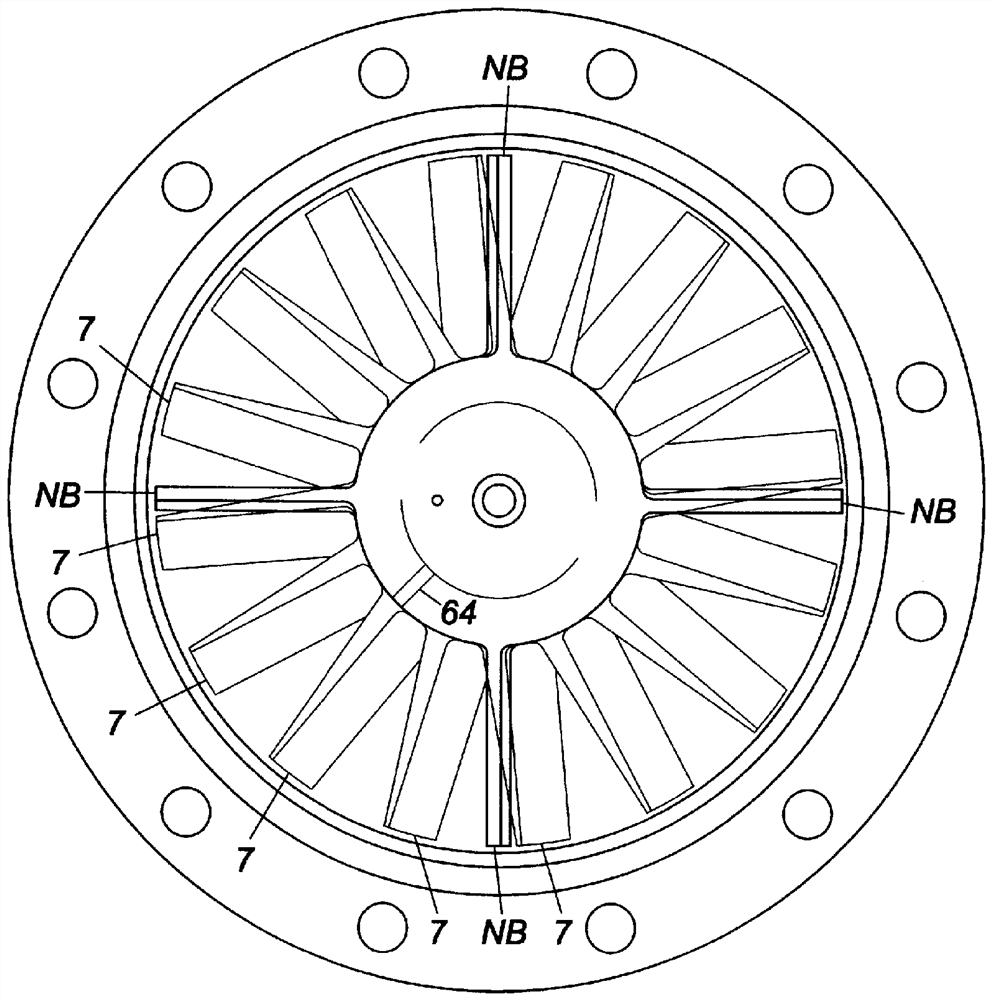

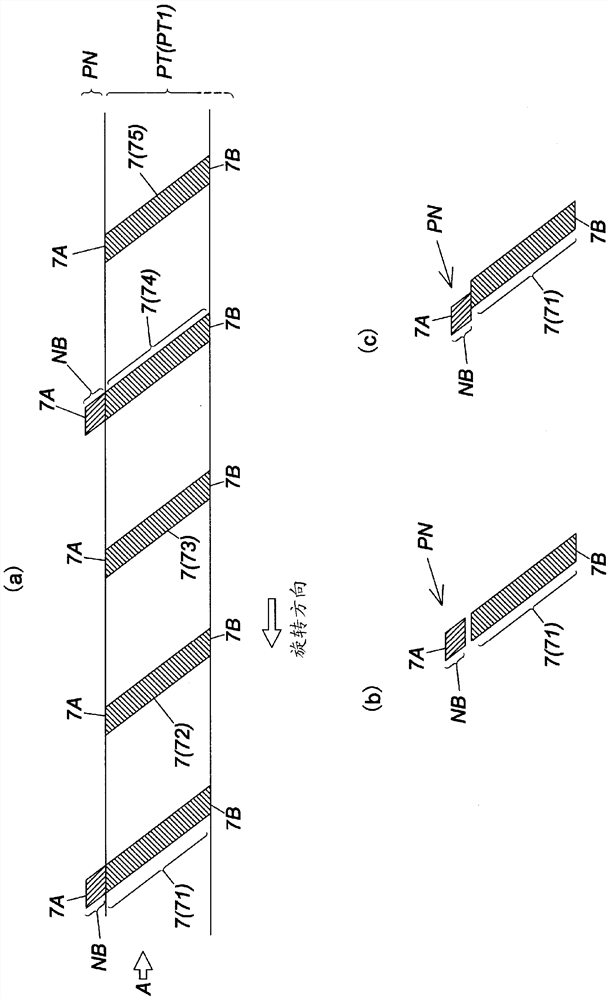

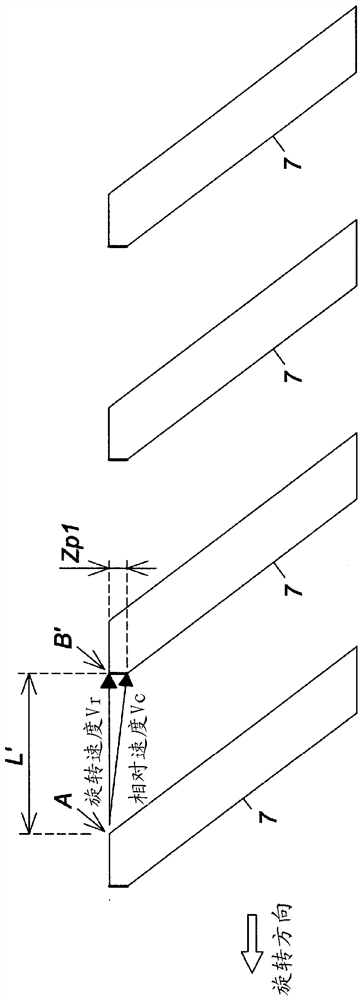

[0066] Hereinafter, the best mode for carrying out the present invention will be described in detail with reference to the drawings. In the present embodiment, as an example of a vacuum pump, a so-called compound vane type turbomolecular pump including a turbomolecular pump unit composed of a plurality of exhaust layers and a screw groove exhaust layer is used as an exhaust mechanism. In addition, this embodiment can also be applied to a pump having only a turbomolecular pump unit.

[0067] figure 1 It is a cross-sectional view of a vacuum pump to which the present invention is applied.

[0068] If refer to figure 1 , the vacuum pump P1 in the figure includes an outer case 1 having a cylindrical cross-section, a rotor 6 arranged in the outer case 1 , a support mechanism for rotatably supporting the rotor 6 , and a drive mechanism for rotationally driving the rotor 6 .

[0069] The outer casing 1 has a bottomed cylindrical shape in which a cylindrical pump casing 1A and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com