A method for correcting lithium battery SOC according to dynamic voltage

A dynamic voltage and lithium battery technology, applied in battery/fuel cell control devices, electric vehicles, vehicle components, etc., can solve problems such as large SOC error, accuracy dependence of ampere-hour integration algorithm, SOC jump, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

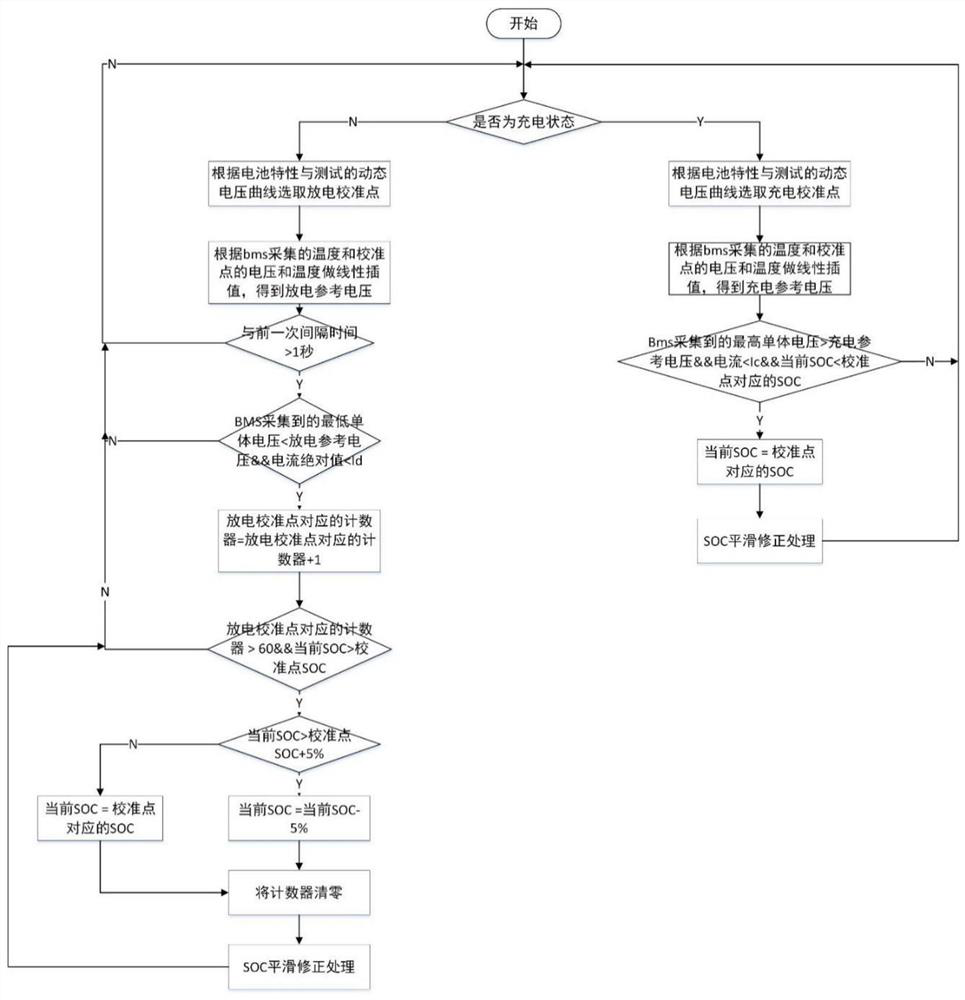

[0035] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

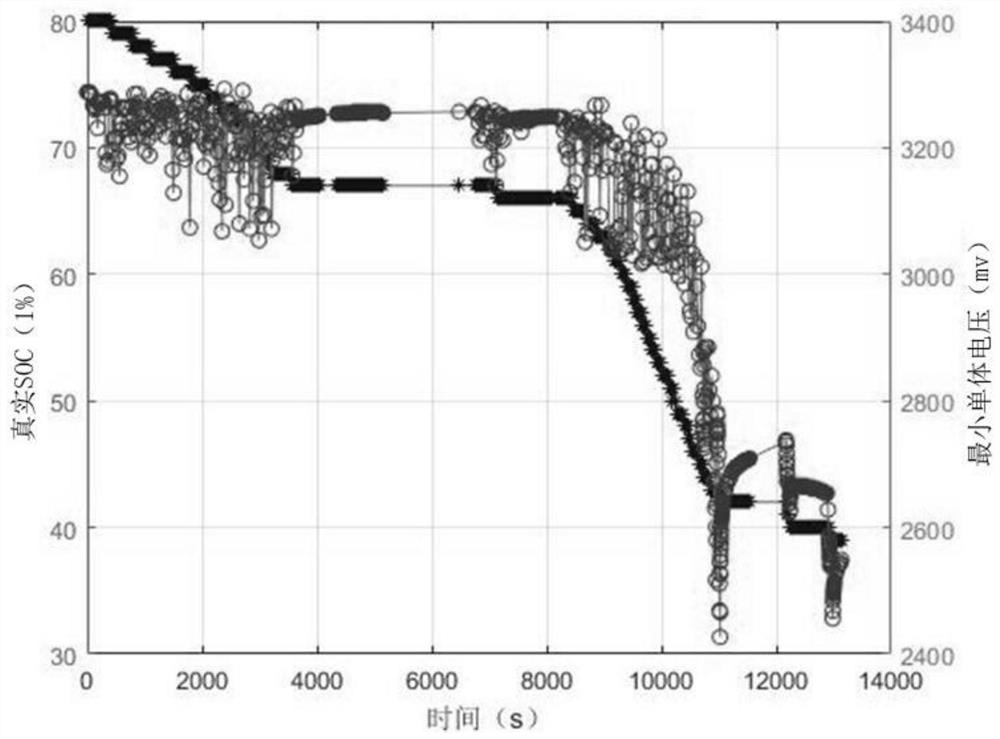

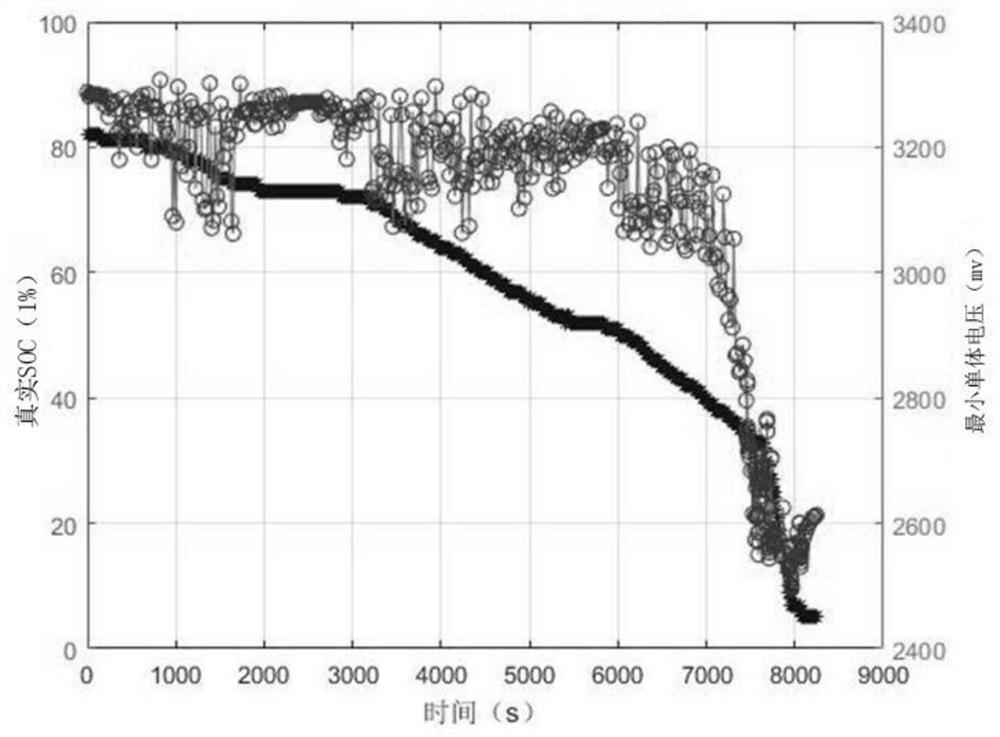

[0036] Lithium batteries have the following battery characteristics. During charging at a fixed rate and constant current, the dynamic terminal voltage curve is in a monotonically increasing state, and in the process of charging and discharging at a fixed rate and constant current, the dynamic terminal voltage curve is in a monotonically decreasing state. When a lithium battery is charged and discharged at a fixed rate at a fixed temperature, the dynamic terminal voltage is the same as the static OCV, and its dynamic terminal voltage variation curve and OCV curve show the same characteristics, that is, the dynamic terminal voltage and SOC will also show a one-to-one correspondence. . The analysis of charge-discharge curves with different rates has the following rules: the closer the charge-discharge current rate is to 0, the clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com