A kind of preparation method of superhydrophobic anti-reflection coating with high light transmittance

An anti-reflection coating, high light transmittance technology, applied in the field of inorganic functional materials, can solve the problems of low average light transmittance of AR films, and achieve the effects of improving optical performance, easy operation, and resisting structure collapse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

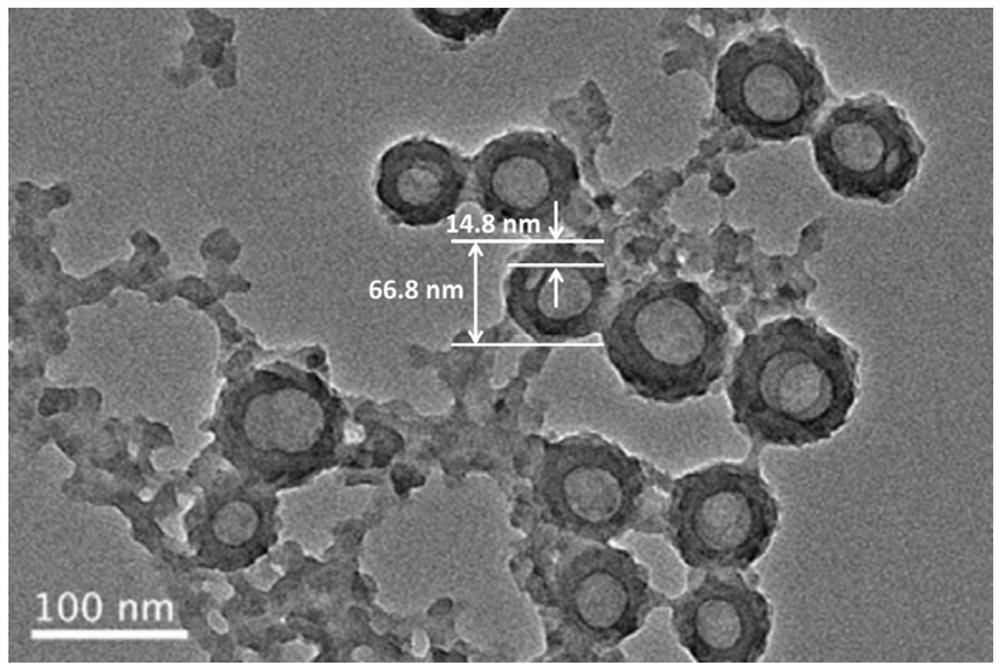

[0023] (1) Weigh 0.12g of PAA and place it in a beaker, add 7.0mL of ammonia water, mix evenly with the wrist, slowly add 120mL of absolute ethanol solvent under the condition of vigorous stirring (multi-head stirrer), and transfer the beaker to 50 ℃ into a constant temperature magnetic stirrer, the first co-precursor TEOS / FAS (15:1 molar ratio) was added dropwise and stirred for 18 hours to obtain a light blue TF sol.

[0024] (2) According to n(HMDS):n(TEOS)=2:1, the second precursor HMDS was added to the TF sol, stirred at ambient temperature for 12 hours and aged for 4 days to obtain TF-H sol. Among them, Si 总 (total amount of TEOS / FAS and HMDS): PAA: EtOH: NH 3 ·H 2 The final molar ratio of O was 1:0.019:2.113:23.854.

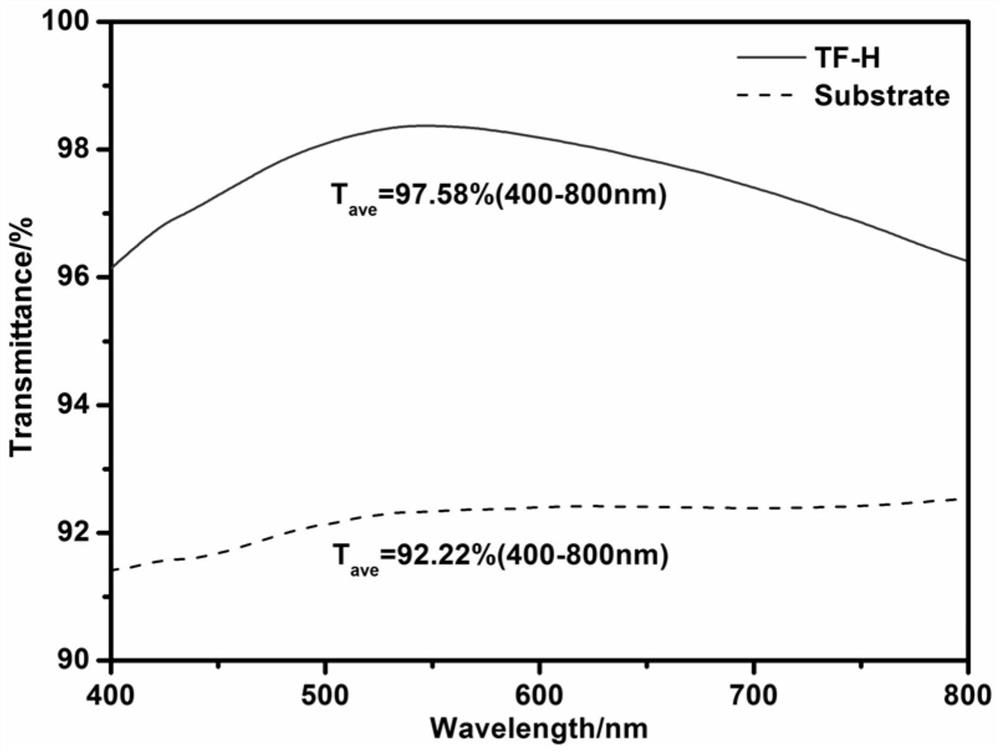

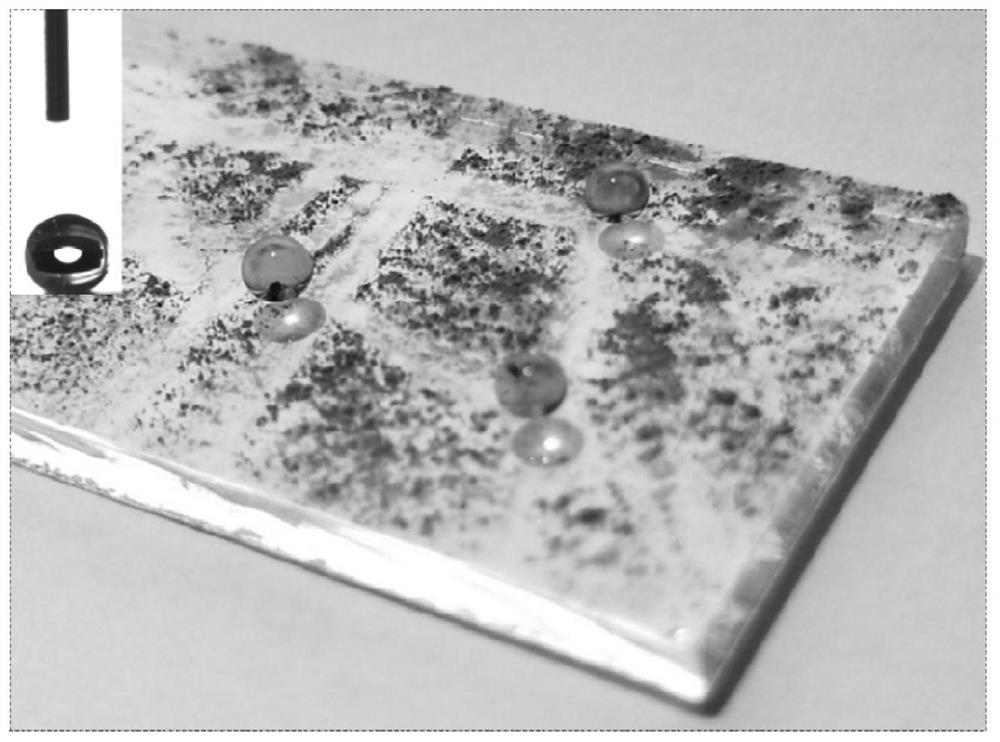

[0025] (3) TF-H sol was deposited on the cleaned glass substrate by dipping-pulling method. The coating was cured in an oven at 100°C for 1 hour, and then calcined in a muffle furnace at 350°C for 2 hours. Finally, the average light transmittance in th...

Embodiment 2

[0027] (1) Weigh 0.12g of PAA and place it in a beaker, add 7.0mL of ammonia water, mix evenly with the wrist, slowly add 120mL of absolute ethanol solvent under the condition of vigorous stirring (multi-head stirrer), and transfer the beaker to 50 ℃ into a constant temperature magnetic stirrer, the first co-precursor TEOS / FAS (10:1 molar ratio) was added dropwise, and stirred for 14 hours to obtain a light blue TF sol.

[0028] (2) Add the second precursor HMDS to the TF sol according to n(HMDS):n(TEOS)=2:1, stir at ambient temperature for 10 h and age for 5 days to obtain TF-H sol. Among them, Si 总 (total amount of TEOS / FAS and HMDS): PAA: EtOH: NH 3 ·H 2 The final molar ratio of O was 1:0.019:2.099:23.705.

[0029] (3) TF-H sol was deposited on the cleaned glass substrate by dipping-pulling method. The coating was cured in an oven at 100°C for 1 hour, and then calcined in a muffle furnace at 350°C for 2 hours. Finally, the average light transmittance in the visible ligh...

Embodiment 3

[0031] (1) Weigh 0.12g of PAA and place it in a beaker, add 7.0mL of ammonia water, mix evenly with the wrist, slowly add 120mL of absolute ethanol solvent under the condition of vigorous stirring (multi-head stirrer), and transfer the beaker to 50 ℃ into a constant temperature magnetic stirrer, the first co-precursor TEOS / FAS (10:1 molar ratio) was added dropwise and stirred for 12 hours to obtain a light blue TF sol.

[0032] (2) Add the second precursor HMDS to the TF sol according to n(HMDS):n(TEOS)=1:1, stir at ambient temperature for 8 hours and age for 3 days to obtain TF-H sol. Among them, Si 总 (total amount of TEOS / FAS and HMDS): PAA: EtOH: NH 3 ·H 2 The final molar ratio of O was 1:0.032:3.454:39.002.

[0033](3) TF-H sol was deposited on the cleaned glass substrate by dipping-pulling method. The coating was cured in an oven at 100°C for 1 hour, and then calcined in a muffle furnace at 350°C for 2 hours. Finally, the average light transmittance in the visible lig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com