Preparation method and application for two-dimensional metal organic framework nanosheet

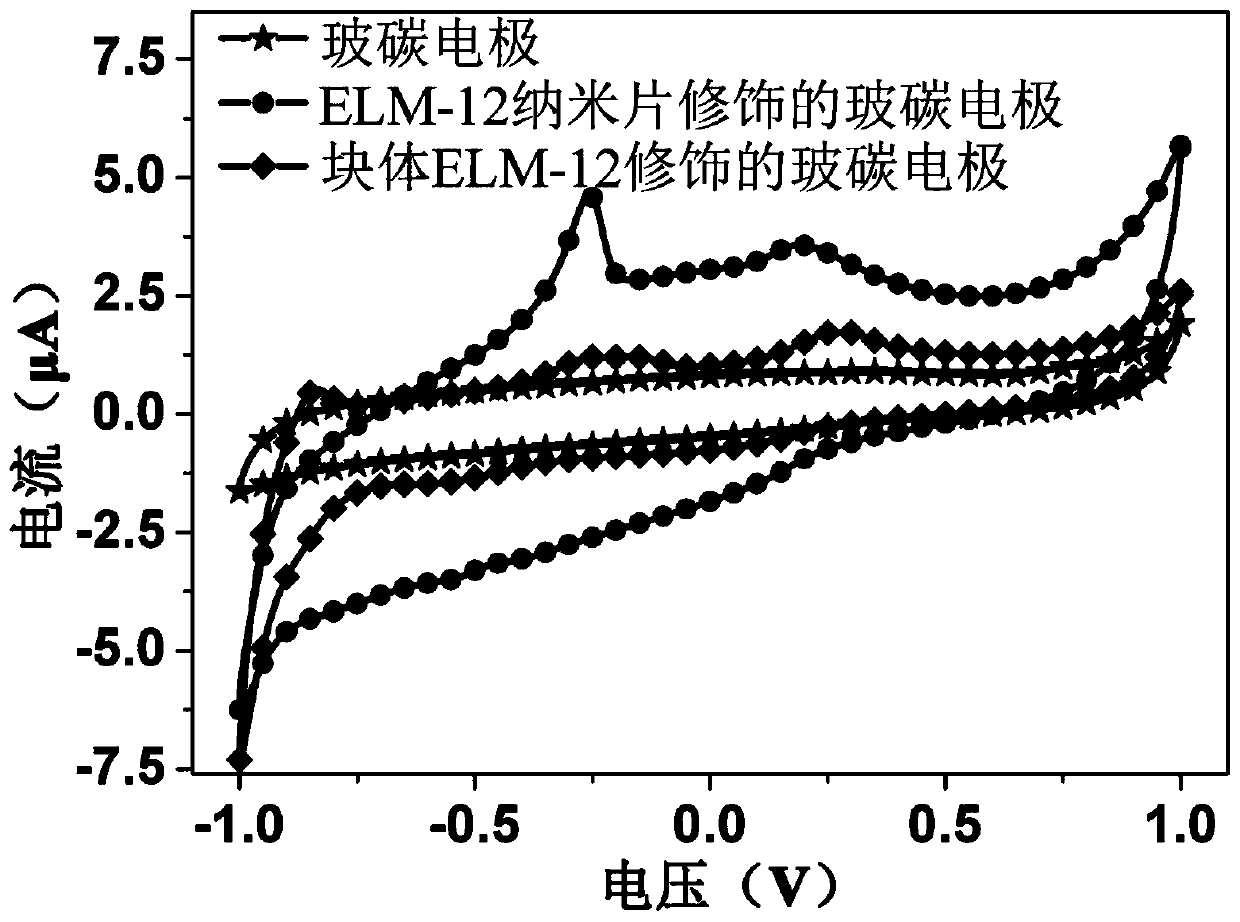

A metal-organic framework, organic framework technology, applied in nanotechnology, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc. problem, to achieve the effect of promoting industrial application, strong electrochemical signal, excellent catalytic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

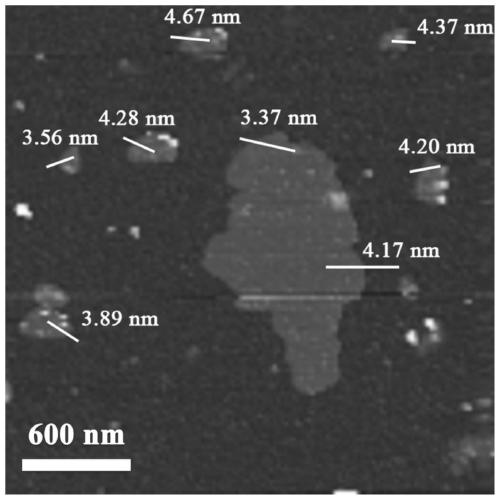

[0048] The preparation of embodiment 1 ELM-12 nano sheet

[0049]Weigh 150 mg bulk layered metal organic framework ELM-12 and place it in a 500 mL glass beaker, then add 150 mL of acetone into the beaker. A commercial homogenizer (model: IKA RW20digital) was used to stir for 8 h at a stirring speed of 2000 rpm. In order to prevent the homogenizer with continuous stirring from overheating, intermittent stirring is adopted, that is, stirring for 1 hour and stopping for 0.5 hour. In addition, the organic solvent will volatilize during the stirring process, so the corresponding organic solvent is added during each stirring interval to keep the solvent volume in the beaker at 150 mL. In order to prevent the bulk metal-organic frameworks from settling in the center of the vortex of the solution during the stirring process, a magnetic rotor was added at the bottom of the beaker to stir to prevent the bulk metal-organic frameworks from settling and aggregating. After the stirring wa...

Embodiment 2

[0051] Example 2 Preparation of MOF-2 nanosheets

[0052] Compared with the preparation method of ELM-12 nanosheets in Example 1, the difference is that 150 mg of bulk MOF-2 is weighed and dispersed in 150 mL of acetone, and the rest of the steps and conditions are the same. After centrifuging and concentrating the obtained two-dimensional metal-organic framework nanosheet dispersion, a high-concentration MOF-2 nanosheet acetone dispersion is obtained.

Embodiment 3

[0053] Example 3 Preparation of Cu-TCPP nanosheets

[0054] Compared with the preparation method of ELM-12 nanosheets in Example 1, the difference is that 150 mg bulk Cu-TCPP was weighed and dispersed into 150 mL ethanol, and the rest of the steps and conditions were the same. After centrifuging and concentrating the obtained two-dimensional metal-organic framework nanosheet dispersion, a Cu-TCPP nanosheet ethanol dispersion with a higher concentration was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com