Construction process for indoor drainage ditch

A construction technique and drainage ditch technology, which is applied in waterway systems, water supply devices, sewer pipe systems, etc., can solve problems such as difficulty in ensuring straightness of ditch boundaries, displacement of formwork, and difficulty in determining clearance dimensions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

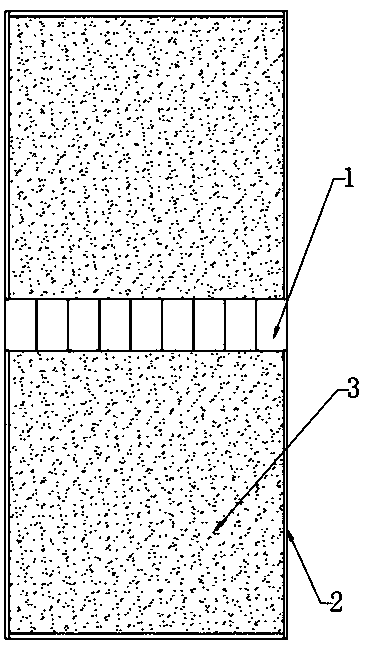

[0020] The indoor drainage ditch construction technology provided in this embodiment includes the following steps: S1, pre-preparation, preparing formwork of corresponding size and quantity, setting-out tools, excavation equipment and concrete mixing device, and at the same time, prefabricating steel pipes in the factory according to design standards Mixed structure ditch cover 1; S2, according to the design requirements, measuring and setting out at the construction position of the drainage ditch, and springing or pulling two thin lines according to the design width of the ditch when setting out; Within the construction range of the ditch, excavate several deep pits at intervals, and place multiple stakes at intervals in each deep pit, the height of the stakes is the sum of the design elevation of the ditch and the cushion layer; S4, earthwork excavation , using excavation equipment to excavate the earth within the construction range of the ditch formed after setting out the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com