Flow guide layer of paper diaper with lawn structure and preparation method of flow guide layer

A diaper and diversion layer technology, applied in the field of diapers, can solve the problems that the diversion effect of the diversion layer cannot be greatly improved, reduce the dryness and comfort of the diaper, and cannot break through the limitations, etc., so as to reduce the product packaging volume. , speed up the absorption, reduce the effect of collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

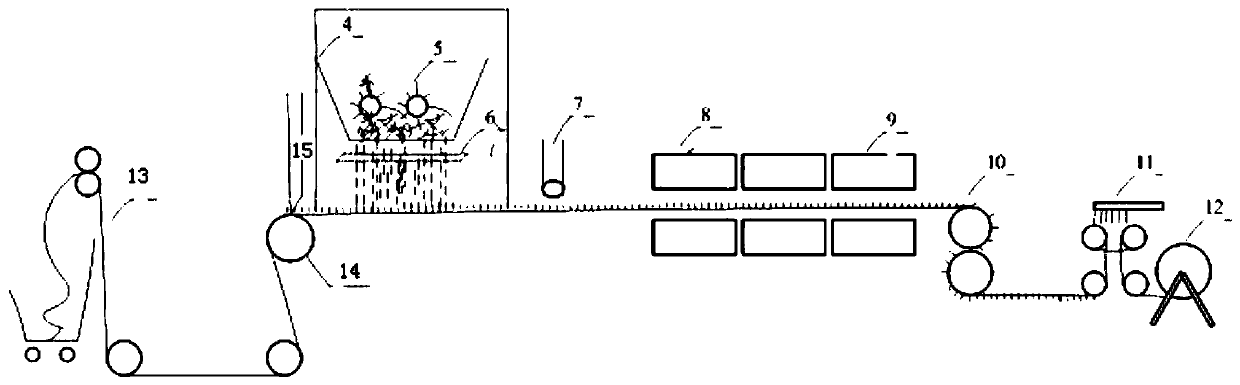

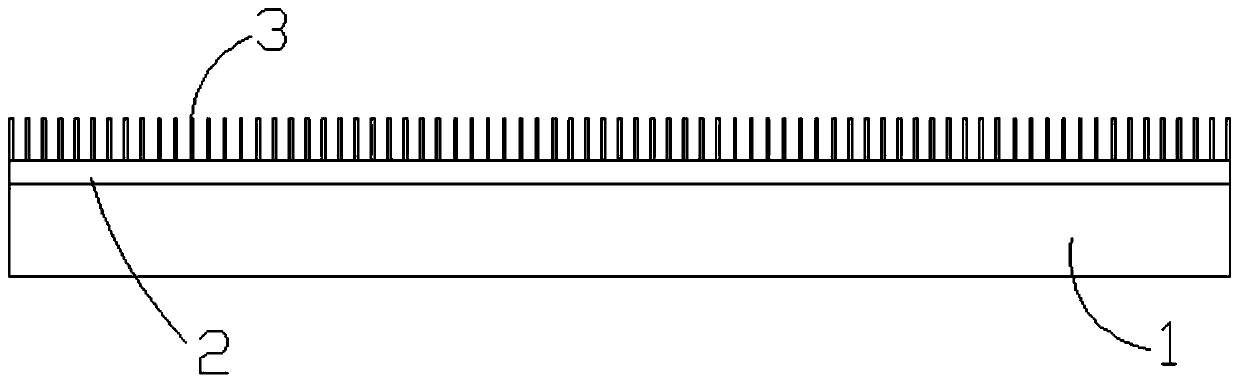

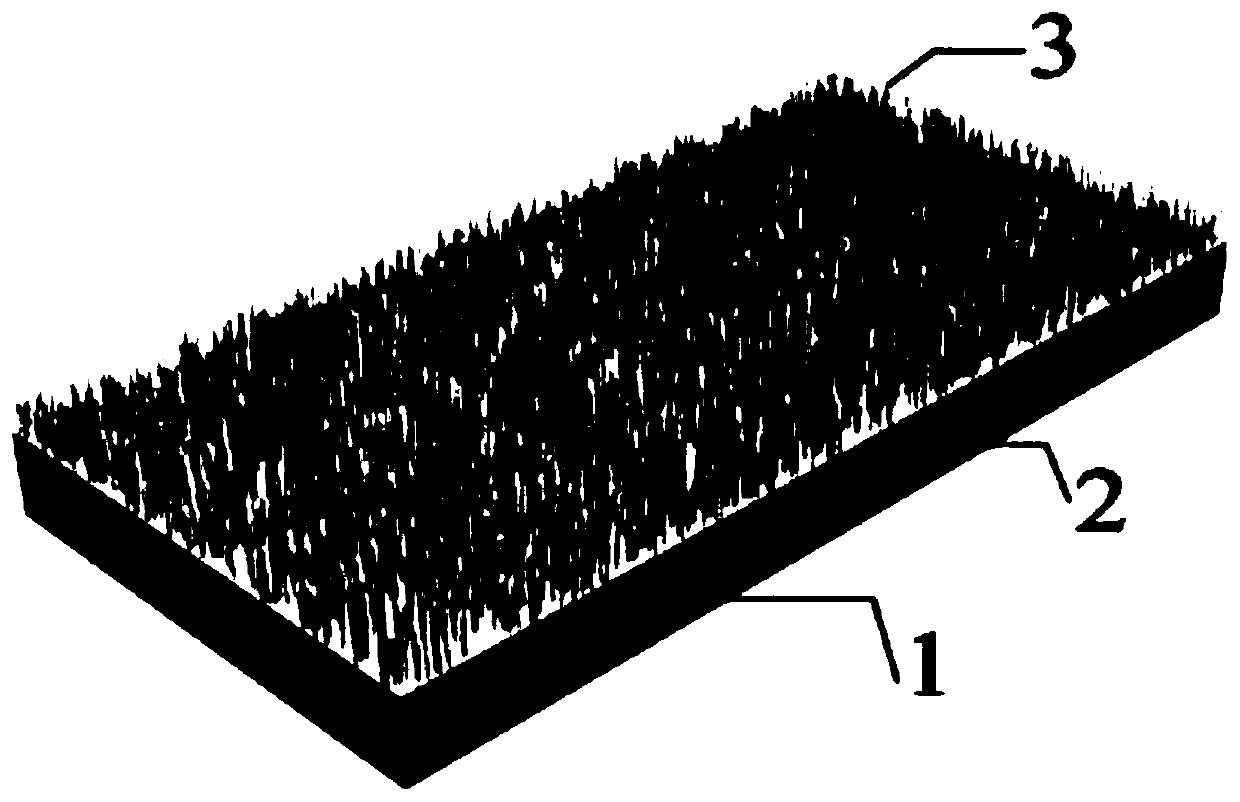

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0030] Related terms are explained below:

[0031] Acquisition layer: Acquisition layer is a general term that refers to a layer of non-woven material applied to sanitary products such as baby diapers, placed between the surface material and the absorbent core, which can effectively help liquid flow from the surface layer to the absorbent core. The liquid conducts quickly and spreads the liquid, so that the liquid leaves the user's skin quickly and keeps the skin dry.

[0032] Ultra-short fiber: The concept of a "lawn structure" ultra-short fiber is proposed in this application, which refers to nylon fiber or polyester fiber with a length of 0.4-1 mm obtained by cutting in this embodiment.

[0033] Nonwoven base fabric: The nonwoven base fabric is the base material for the implantation of ultra-short fibers in this embodiment, and is mainly co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com