Sweat-resistant leather and preparation method thereof

A sweat-resistant and leather technology, applied in the leather field, can solve the problems of intolerant sweat, odor, easy to cover sweat and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

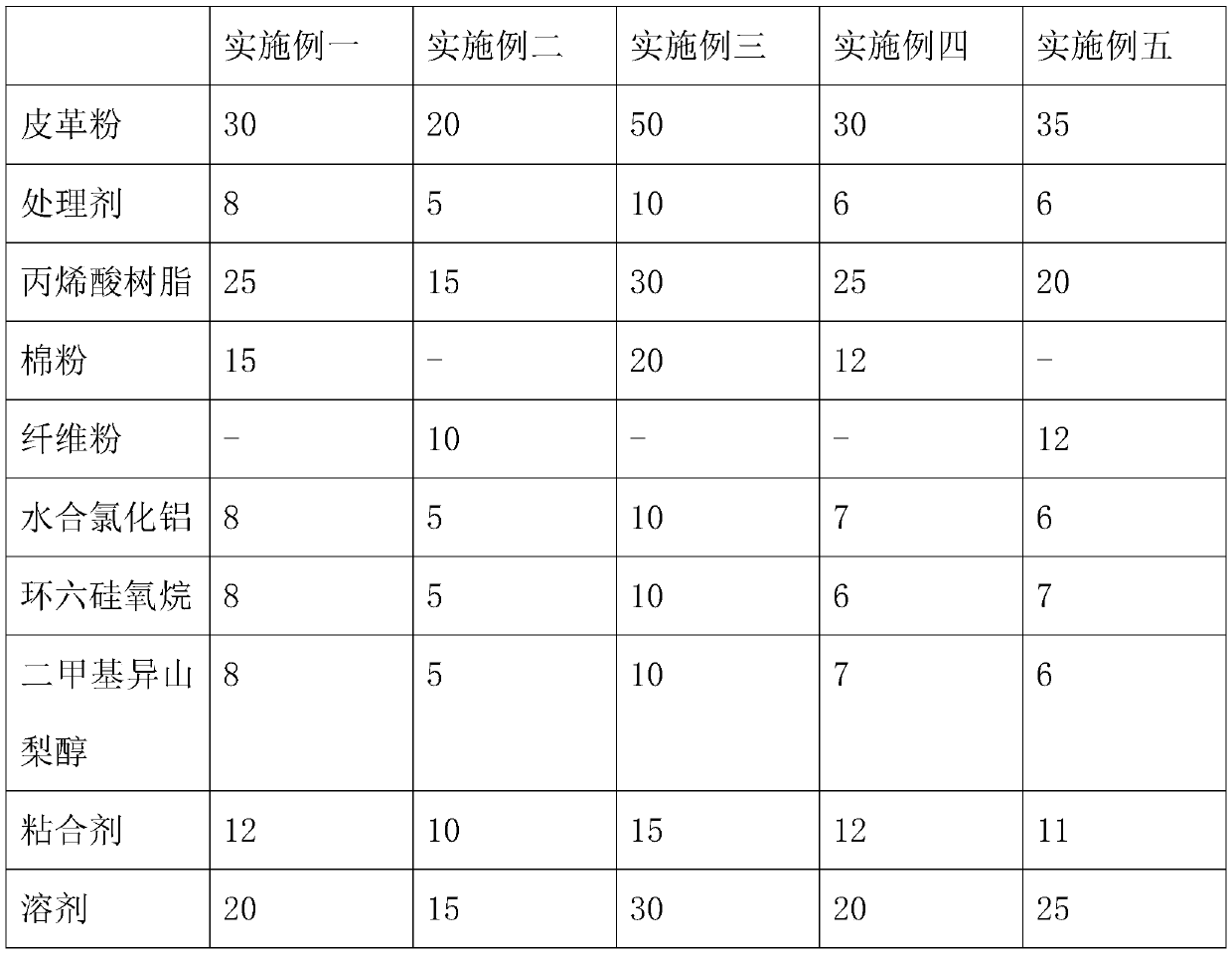

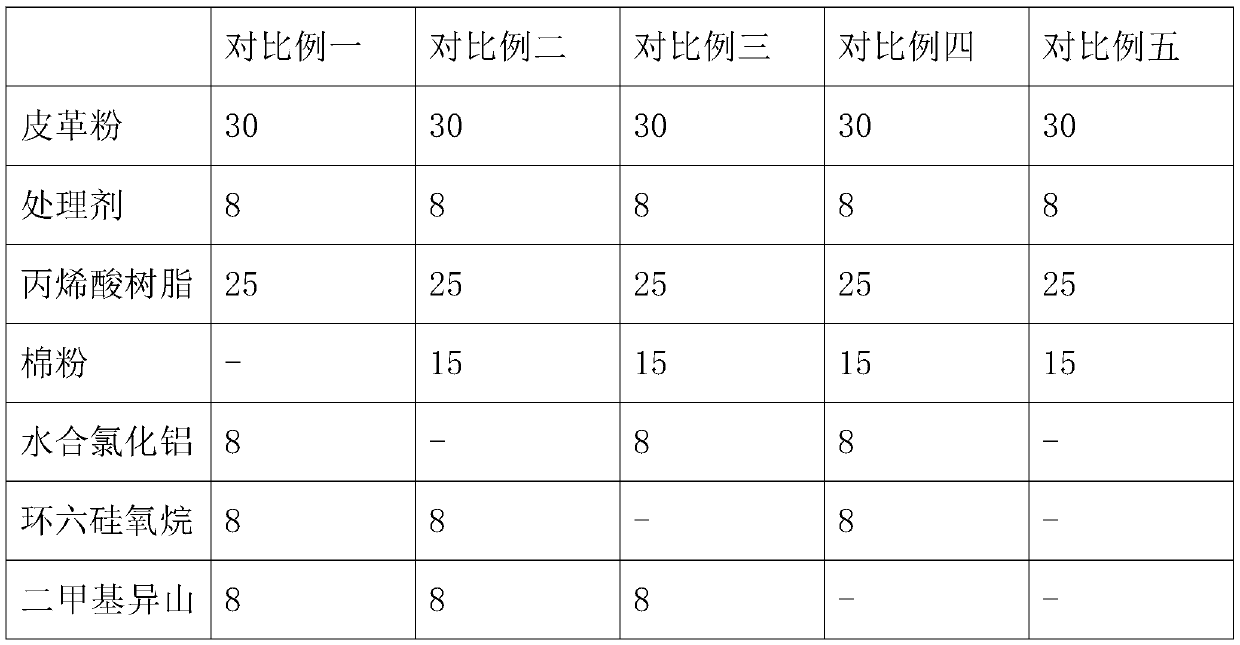

Examples

preparation example Construction

[0026] The present invention also protects a method for preparing the above-mentioned sweat-resistant leather, which includes the following steps:

[0027] Add acrylic resin and treatment agent to leather powder, stir and mix evenly, and place it at 50°C-70°C for a period of time to obtain the first intermediate product; add cotton powder or fiber powder, aluminum salt to the first intermediate product , cyclohexasiloxane, dimethylisosorbide, binder and solvent, stir evenly, and dry at 60°C-80°C for a period of time to obtain the second intermediate product; press the second intermediate product under a certain pressure, sweat-resistant layer;

[0028] bonding the sweat-resistant layer to one side of the leather layer through an adhesive;

[0029] The surface of the sweat-resistant layer is coated with silica gel, and the silica gel layer is obtained after drying.

Embodiment 1

[0035] In Example 1, the sweat-resistant layer is made by the following method: grind leather and cotton into powder, add acrylic resin and treatment agent to the leather powder, stir and mix, and place it at 60°C for a period of time to obtain the first Intermediate product: add cotton powder, aluminum chloride hydrate, cyclohexasiloxane, dimethyl isosorbide, binder and solvent to the first intermediate product, stir evenly, and dry at 70°C for 2 hours to obtain the second intermediate product product; the second intermediate product is pressed under a certain pressure into an elastic leather-like layer to obtain a sweat-resistant layer. The treatment agent is made by the following method: add starch, deionized water, and hydrogen peroxide into the reaction container, and keep it warm at 92°C for 1.5 hours to obtain a degraded starch solution; add glutaraldehyde and p-toluene sulfonate to the degraded starch solution acid, control the reaction temperature at 78°C, and react f...

Embodiment 2

[0036]In Example 2, the sweat-resistant layer is made by the following method: the leather and the fiber are powdered separately, acrylic resin and a treatment agent are added to the leather powder, stirred and mixed, and left for a period of time under an environment of 50° C. to obtain the first Intermediate product: add fiber powder, aluminum chloride hydrate, cyclohexasiloxane, dimethyl isosorbide, binder and solvent to the first intermediate product, stir evenly, and dry at 60°C for 1 hour to obtain the second intermediate product product; the second intermediate product is pressed under a certain pressure into an elastic leather-like layer to obtain a sweat-resistant layer. The treatment agent is made by the following method: add starch, deionized water, and hydrogen peroxide into the reaction vessel, and keep it warm at 90°C for 2 hours to obtain a degraded starch solution; add glutaraldehyde and p-toluenesulfonic acid to the degraded starch solution to control The reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com