Rotary wing type full speed vector ship stabilizer

A technology of a stabilizer and a rotor is applied in the field of a rotary-wing full-speed vector ship stabilizer, which can solve the problems of increasing the sailing energy of the ship, reducing the service life of the stabilizer, and wasting resources, so as to reduce the sailing resistance of the ship, reduce the The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

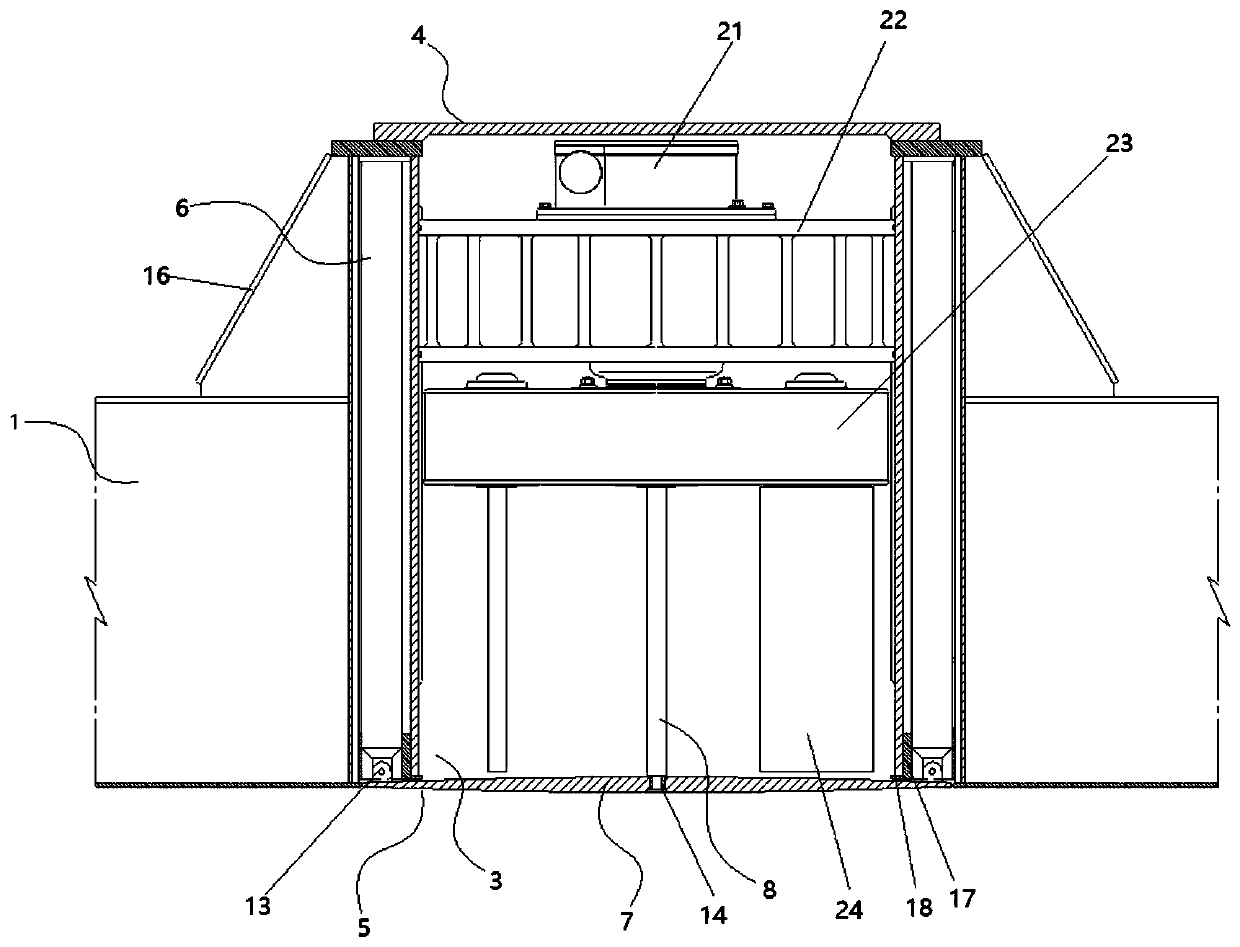

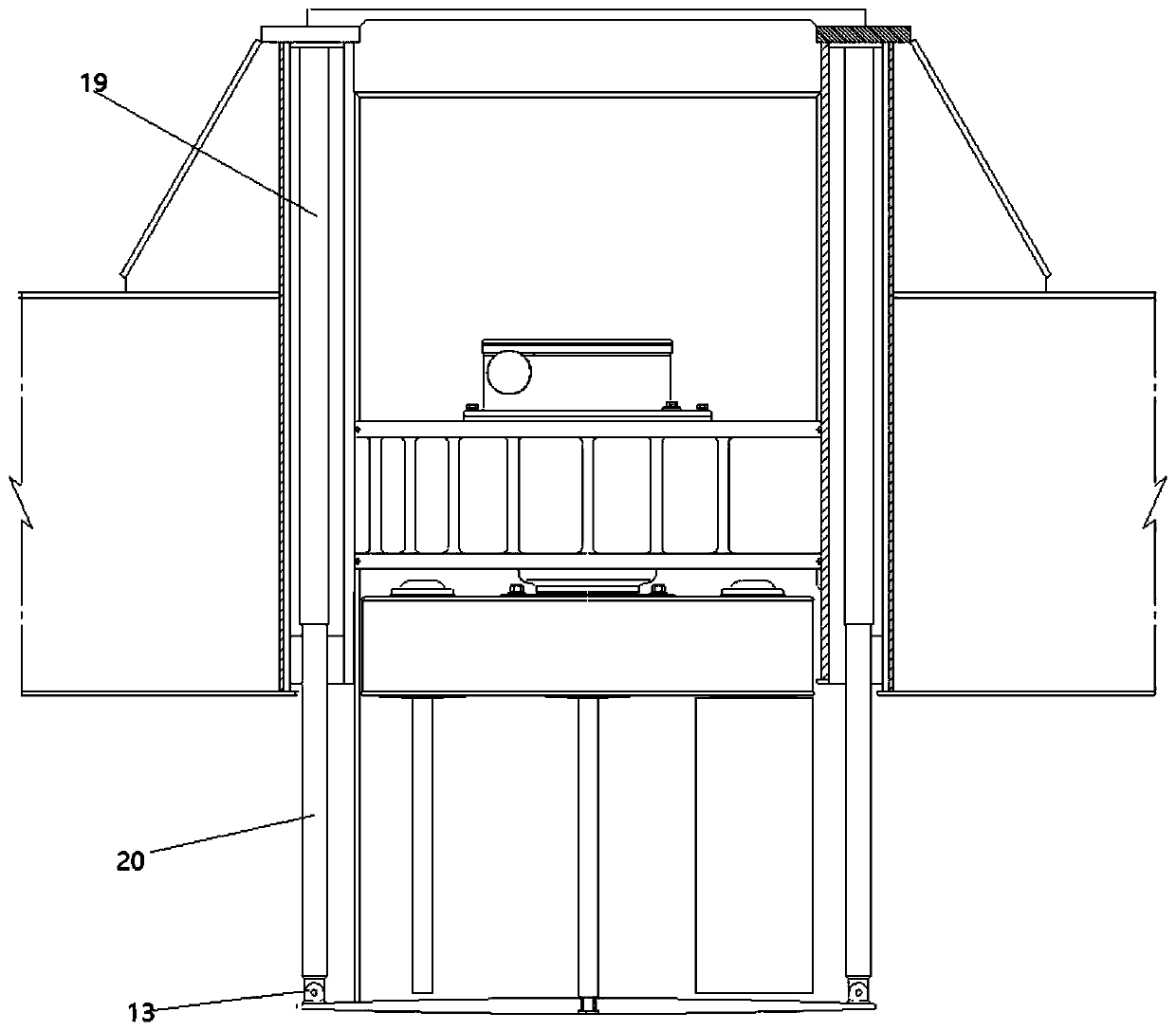

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

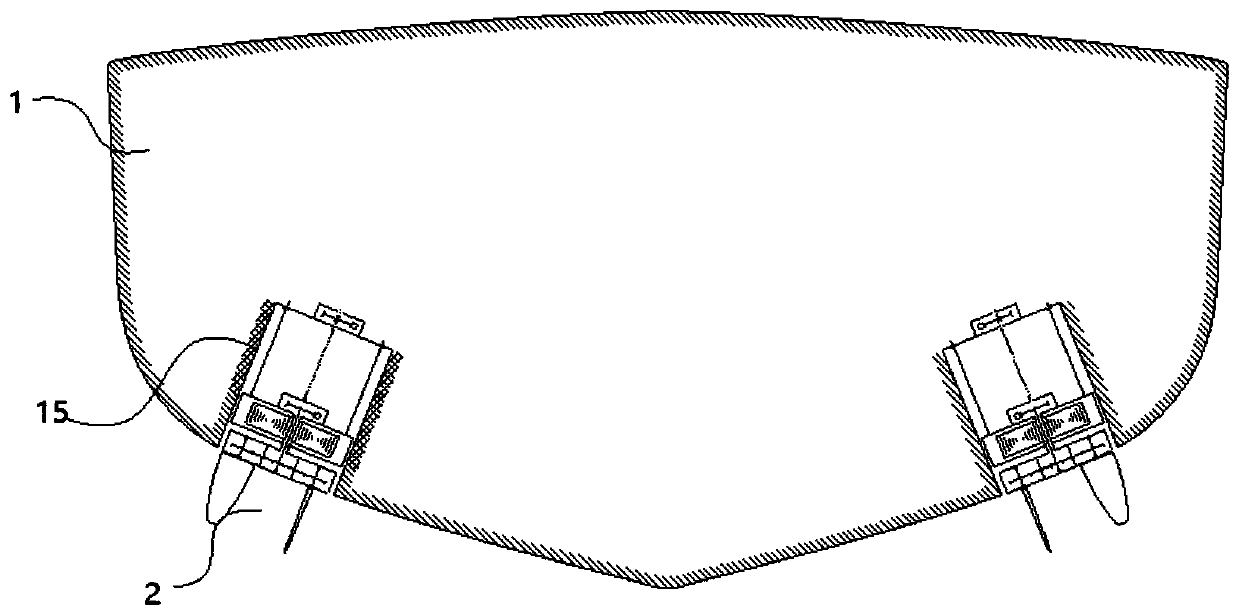

[0027] A rotor type full-speed vector ship stabilizer, the stabilizer includes a prime mover, a machine base, a main shaft, a rotor angle controller, a transmission shaft, a rotating disc, and a central gear, the prime mover drives the main shaft to rotate, and the main shaft is rotatably assembled on Machine base, the lower end of the main shaft is fixedly connected with the upper part of the rotating disc; the drive shaft is extended inside along the main shaft axis, the upper end of the drive shaft is connected with the thrust direction controller, and the lower part rotatably passes through the rotating disc and the central gear in the rotating disc Fixedly connected, the lower end of the drive shaft rotates and cooperates with the bottom of the rotating disc, and the stabilizer 2 is telescopically installed on the hull 1.

[0028] The rotor type full speed vector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com