Polyester fiber sewing thread dyeing process and device thereof

A technology of dyeing device and sewing thread, which is applied in textile processing machine accessories, equipment configuration for processing textile materials, textiles and papermaking, etc. It can solve the problems affecting the quality of textile processing and uneven dyeing, so as to achieve good quality, ensure uniformity, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

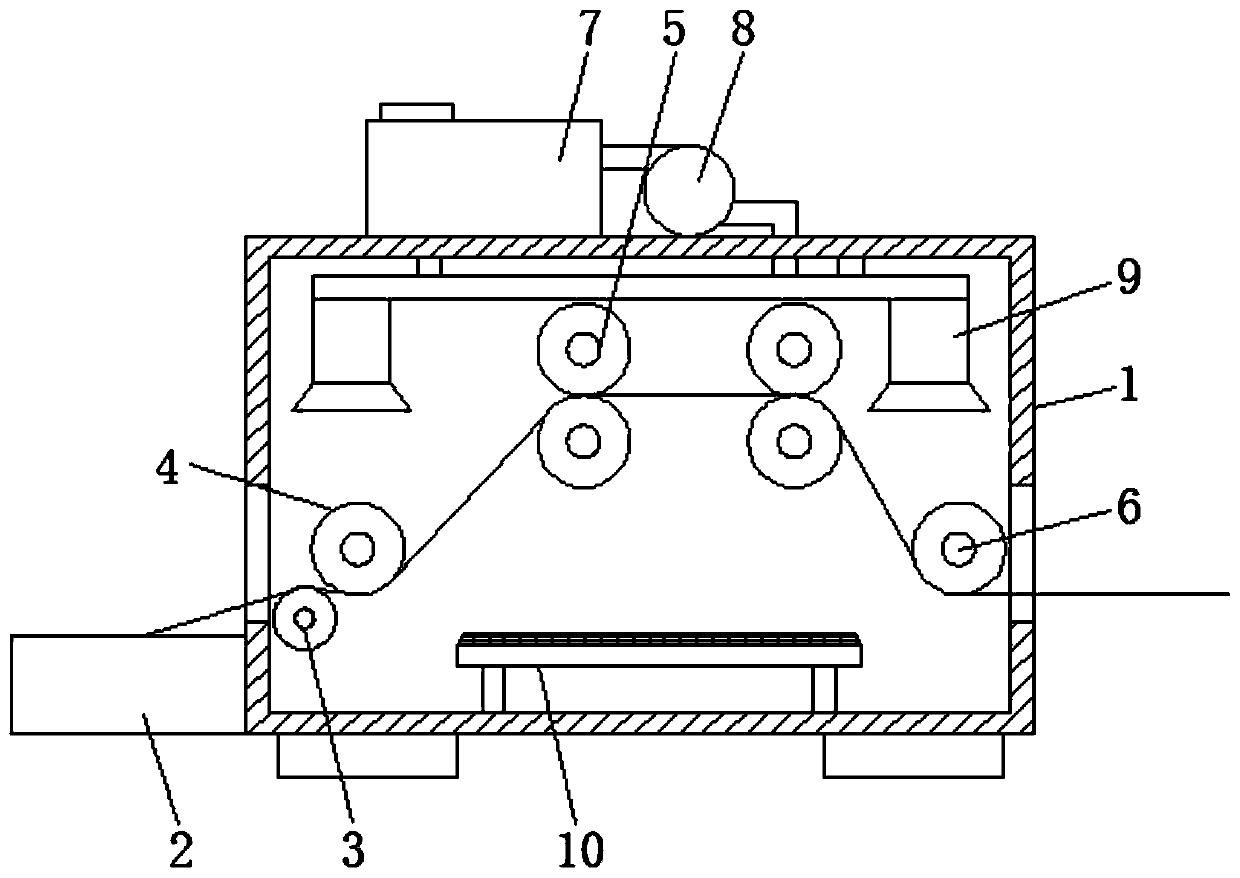

Image

Examples

Embodiment 1

[0025] A polyester sewing thread dyeing process, its operation method comprises the following steps:

[0026] A. The polyester slices are spun into cotton-like short fibers, which are rolled into rovings after cleaning, and further drawn into spun yarns. The spun yarns are twisted and plied to make raw white sewing thread yarns;

[0027] B. Weigh the white sewing thread yarn, measure and calculate the dye content of the standard color when the white sewing thread yarn has not faded, measure and calculate the dye weight of the white sewing thread yarn that has faded color, and compare the white sewing thread with the color card comparison method. Compare the faded part of the yarn with the non-faded part, and calculate the faded color;

[0028] C. Fully mix and precipitate the pre-prepared dyeing agent, and then carry out dyeing processing. The temperature during spraying is 230°C, and the steam dyeing fixation temperature is 350°C; the spraying time is completed within 10 minu...

Embodiment 2

[0031] In embodiment one, add following operation again:

[0032] In step B, according to the principle of how much fading, light, medium and dark dyes with corresponding weights can be obtained; the amount of spray dyeing auxiliaries is 18 times the normal amount of water dyeing method. The amount of various additives, adjust the bath ratio, dissolve the dye and additives in 60°C water, stir well, heat the dye to 260°C, when the pressure reaches 0.2 MPa, turn on the air pump to inflate, and wait for the pressure to increase When it reaches 0.6 MPa, spray dye the various parts of the sewing thread yarn until it is saturated, preferably without dripping the dye solution.

[0033] A polyester sewing thread dyeing process, its operation method comprises the following steps:

[0034] A. The polyester slices are spun into cotton-like short fibers, which are rolled into rovings after cleaning, and further drawn into spun yarns. The spun yarns are twisted and plied to make raw white...

Embodiment 3

[0039] In embodiment two, add following operation again:

[0040] The dyeing raw materials in step C are acid green lotus (purple) 4BNS.3BR60, FBL, acid bright yellow G.20, weak acid yellow 20, 3cs, chai lin red B, acid fuchsin 6B, acid red XB, weak (Pula) Brilliant red B, 10:E.3B-E specific composition, auxiliary formula consists of acetic acid, sulfuric acid, leveling agent, penetrating agent.

[0041] A polyester sewing thread dyeing process, its operation method comprises the following steps:

[0042] A. The polyester slices are spun into cotton-like short fibers, which are rolled into rovings after cleaning, and further drawn into spun yarns. The spun yarns are twisted and plied to make raw white sewing thread yarns;

[0043] B. Weigh the white sewing thread yarn, measure and calculate the dye content of the standard color when the white sewing thread yarn has not faded, measure and calculate the dye weight of the white sewing thread yarn that has faded color, and compare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com