Anti-crack masonry wall and construction method

A masonry wall and wall technology, applied in the direction of walls, electrical components, building components, etc., can solve the problems of tensile resistance, bending resistance, low shear strength, poor energy dissipation capacity, insufficient bonding force, etc., and achieve improved Anti-shear ability, prevent wall cracking, and improve the effect of earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

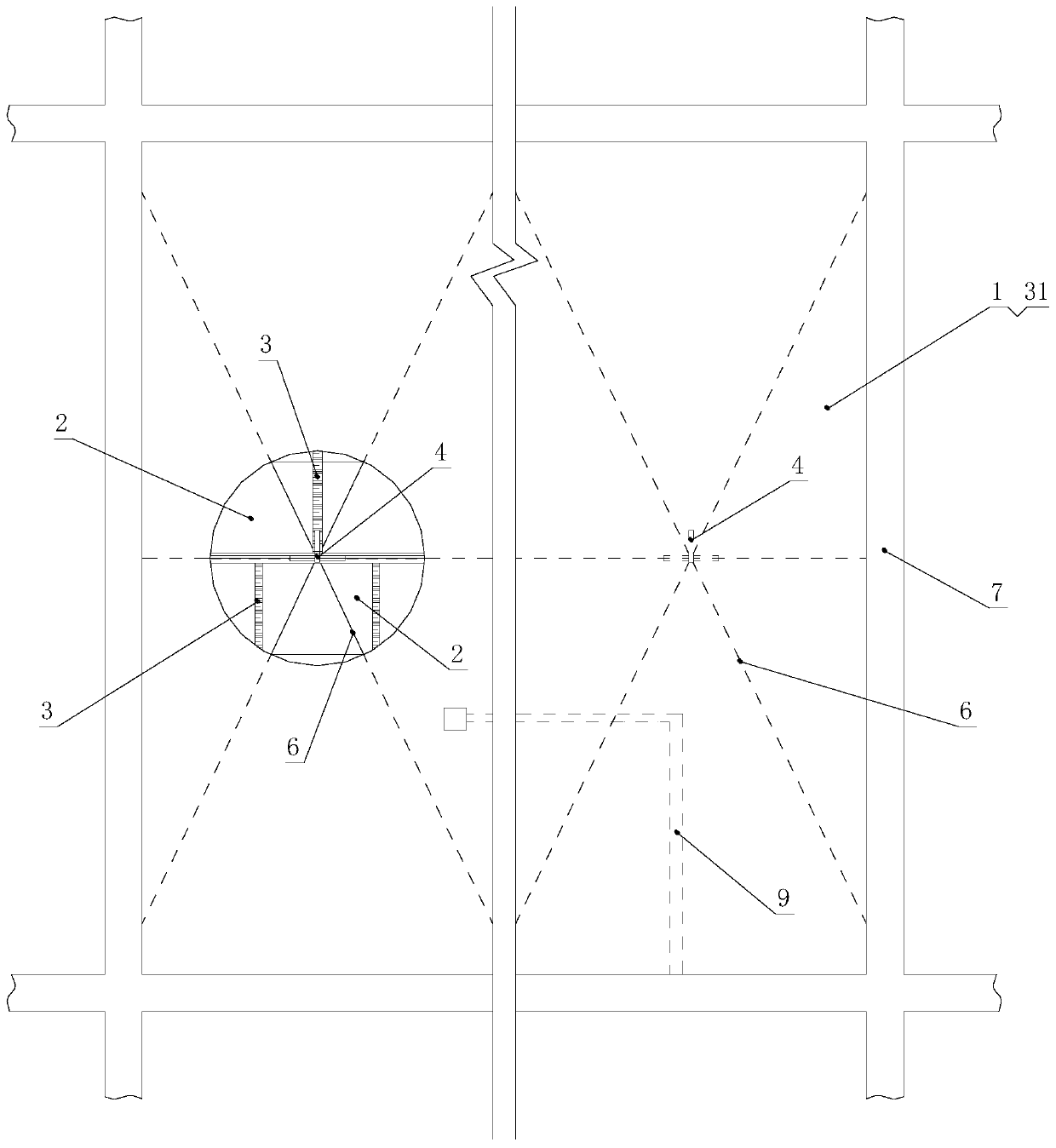

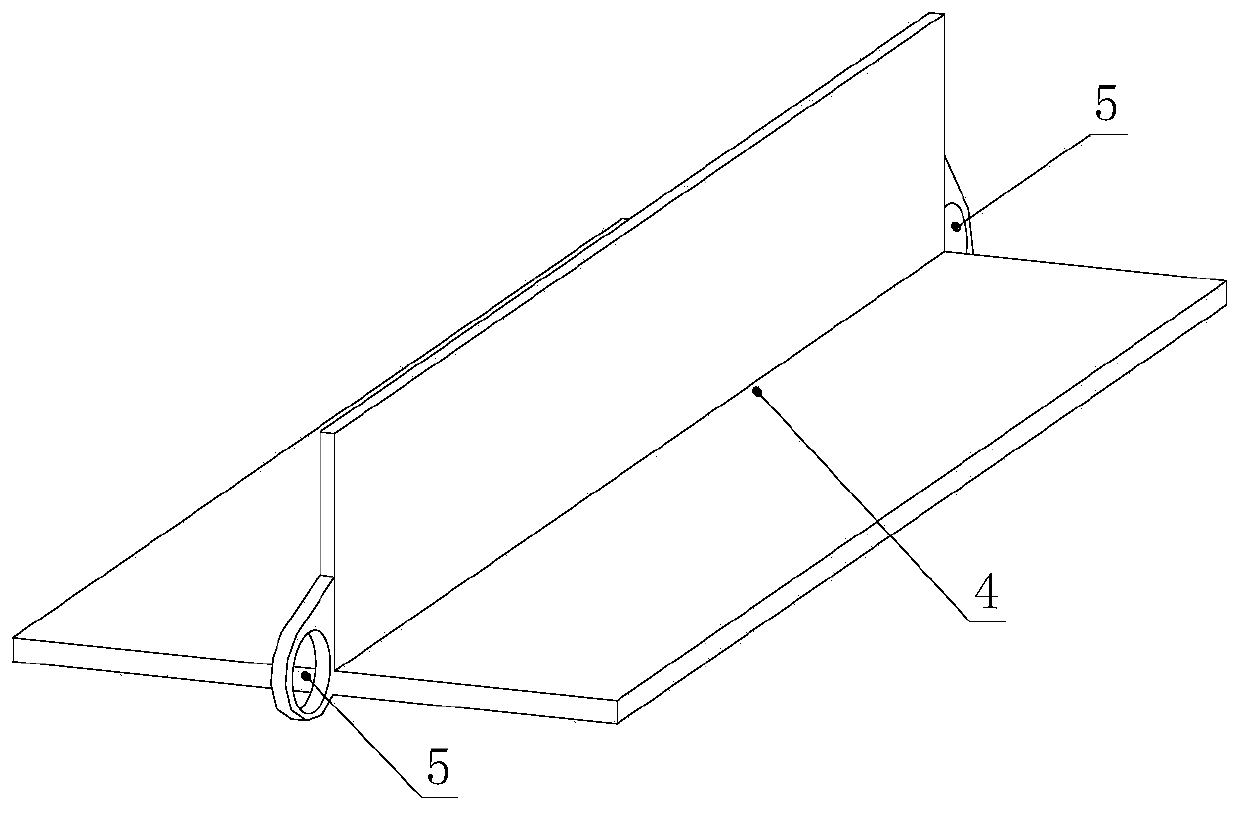

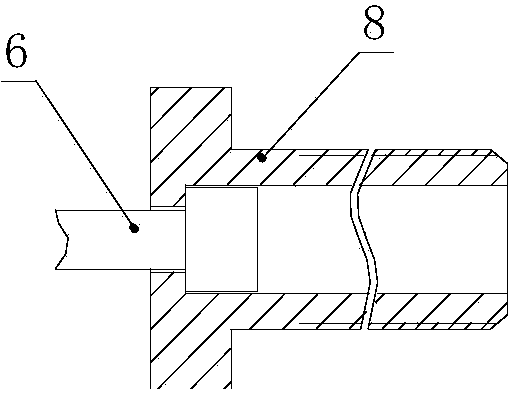

[0035] A crack-resistant masonry wall includes a wall body 1, the wall body 1 is formed by interlaced blocks 2, and the gaps between the blocks 2 are filled with a bonding mortar layer 3. Also includes several connecting pieces 4, said connecting pieces 4 are evenly distributed in the wall body 1 according to certain compartments, in this embodiment, the horizontal intervals of the connecting pieces 4 are between 0.8m and 2m, and the vertical intervals of the connecting pieces 4 are between 0.8m and 2m. The vertical interval is between 0.8 and 1.5m. The connecting piece 4 is embedded in the bonding mortar layer 3, and the connecting piece 4 vertically penetrates the wall 1, that is to say, the connecting piece 4 is located in the gap of the block 2, and the length direction is the same as the width of the wall 1 Direction is vertical. Both ends of the connecting piece 4 are provided with fixing holes 5 , and several reinforcements 6 are provided on both sides of the wall 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com