Feedwater pump recirculation valve state-based feedwater feedforward control system and method

A technology of recirculation valve and feed-forward control, applied in water circulation, separation method, control of water supply, etc., can solve problems such as unfavorable water supply system stable operation, safe operation of feed water pump, sacrifice of equipment life, working fluid flash evaporation and cavitation, etc., to achieve The effect of avoiding long-term low-opening operation, reducing unnecessary opening times, and reducing the risk of impact wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

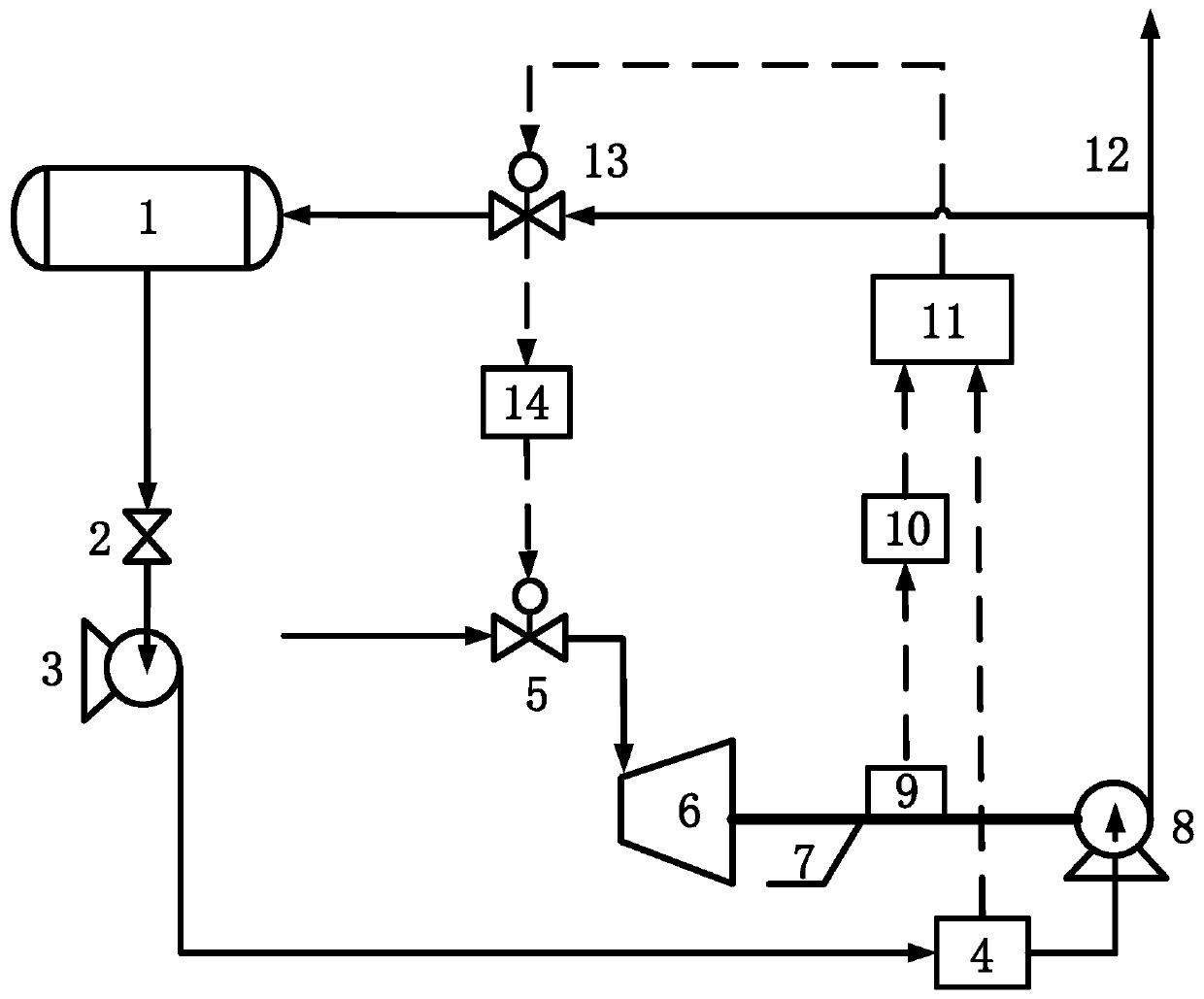

[0026] The present invention is described in further detail below in conjunction with accompanying drawing:

[0027] Such as figure 1 As shown, the feedwater feedforward control system based on the state of the feedwater pump recirculation valve provided by the present invention includes a deaerator 1, a feedwater pump inlet valve 2 and a feedwater pump 3, and a feedwater pump outlet flow sensor 4 is set behind the feedwater pump 3. The feedwater pump regulating device 5 that drives the feedwater pump 3, the feedwater pump small steam turbine 6 connected to the feedwater pump regulating device 5, the variable speed feedwater pump 8 connected to the feedwater pump small steam turbine 6 through the rotating shaft 7, and the rotation speed measurement mounted on the rotating shaft 7 Table 9, the rotational speed measured by the rotational speed measurement table 9 is sent to the minimum feedwater flow calculation module 10 to obtain the minimum feedwater flow limit at this rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com