Plate production system and method with machining information identifying and tracking function

A tracking function and plate production technology, applied in the field of plate processing, can solve the problems of failure to achieve real-time recording and progress tracking of production processes, reduce operating efficiency and intelligent production management, increase system production sequence confusion, and reduce maintenance. cost, improved fault tolerance, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

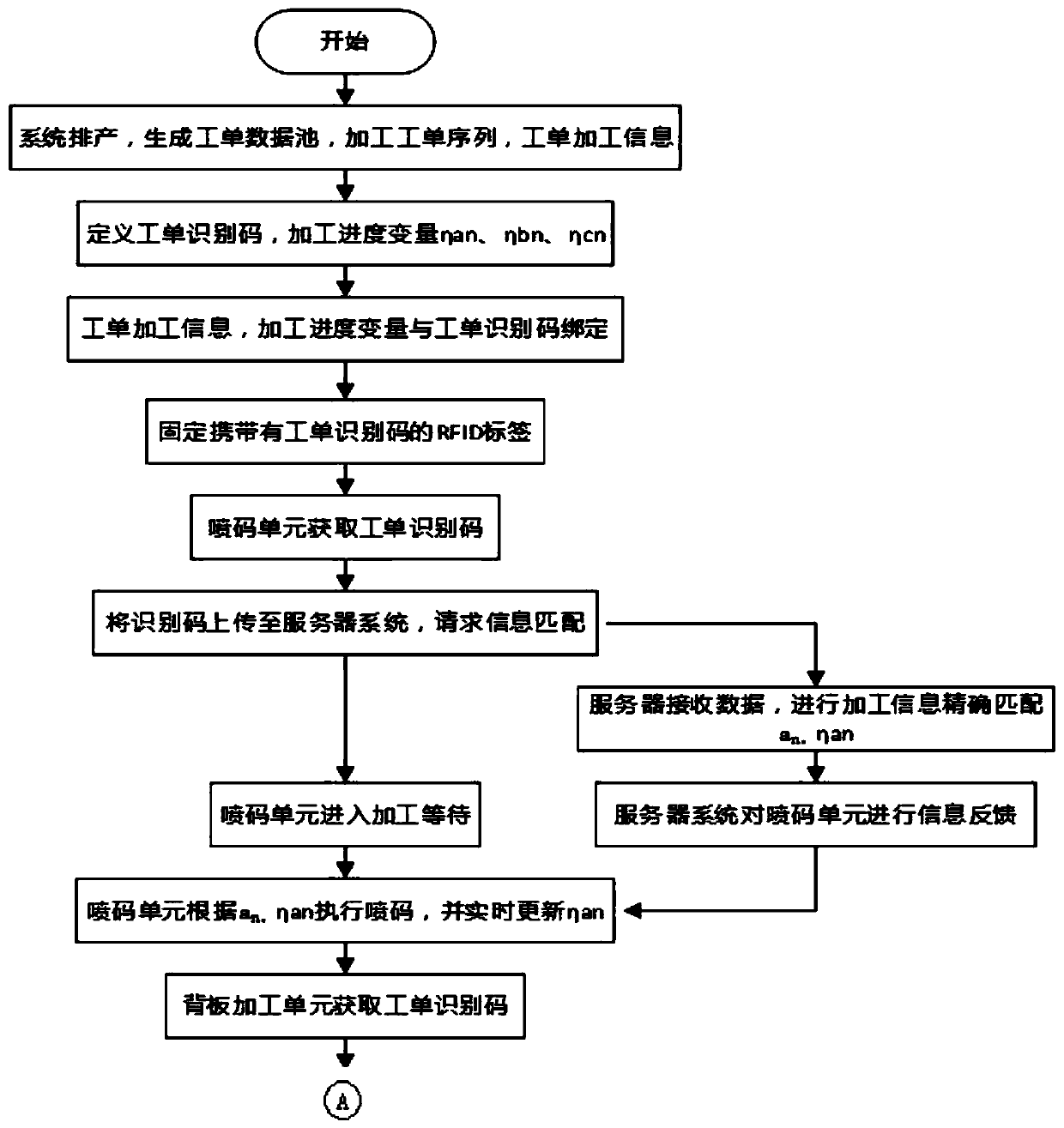

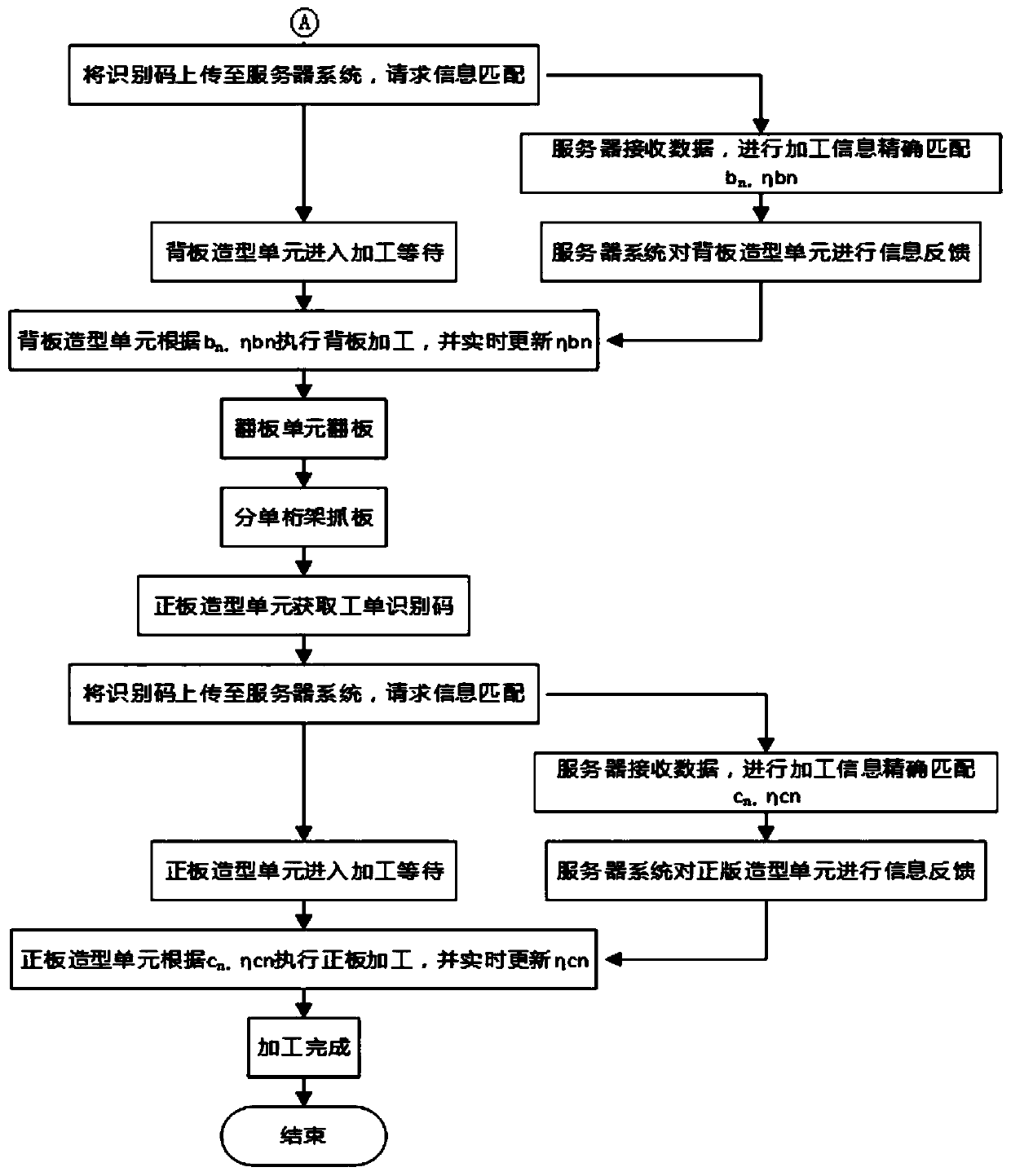

Method used

Image

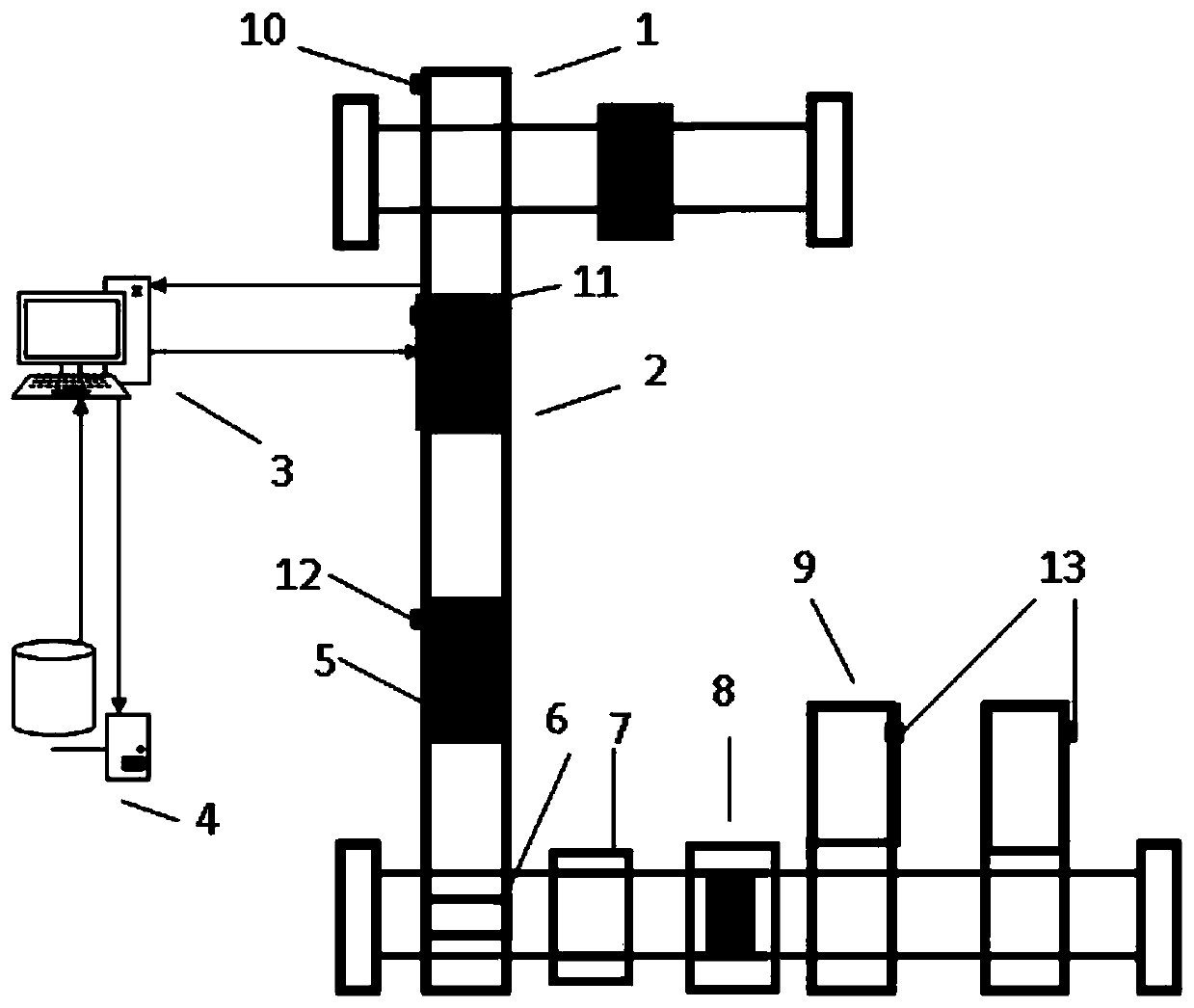

Examples

Embodiment 1

[0078] If the automatic production line is figure 2 In the process of the middle flap unit 6 or the sub-single truss 8, the phenomenon of "dropping" occurs due to insufficient vacuum pressure of the flap unit, air leakage due to uneven panel surface, and insufficient adsorption force of the sub-single truss. At this time, the operator does not need to refer to the processing work order sequence generated during production scheduling, but only needs to restore the sheet work order to the original position of the turnover unit or single truss process to continue processing, without causing the sheet work order to fail. The processing sequence is disordered, and the processing efficiency of the production line will not be reduced.

Embodiment 2

[0080] If special circumstances such as power outages occur in the system, as shown in Table 1, the original system will not only lead to disordered work order processing sequence, but also fail to record the current processing progress of each processing unit. In the present invention, the server system can determine the real-time processing status of work orders on the current automatic production line according to the processing progress variable values of each part of the production line. The processing progress variable corresponding to the order, such as the processing progress variable η of the work order 3 on the inkjet unit at this time an3 =45%, work order 2 processing progress variable η on the back panel molding unit bn2 =67%, work order 1 processing progress variable η on the positive plate molding unit cn1 =90%, and continue processing at the breakpoints of 45%, 67%, and 90% of the processing progress, avoiding waste of time due to repeated processing operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com