Gas-steam combined cycle distributed energy three-power quick-cutting system and method

A distributed energy, gas steam technology, applied in the direction of emergency power supply arrangements, electrical components, circuit devices, etc., can solve the problems that cannot meet the needs of distributed energy power stations, and achieve the goals of reducing equipment investment, limiting short-circuit current, and saving floor space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

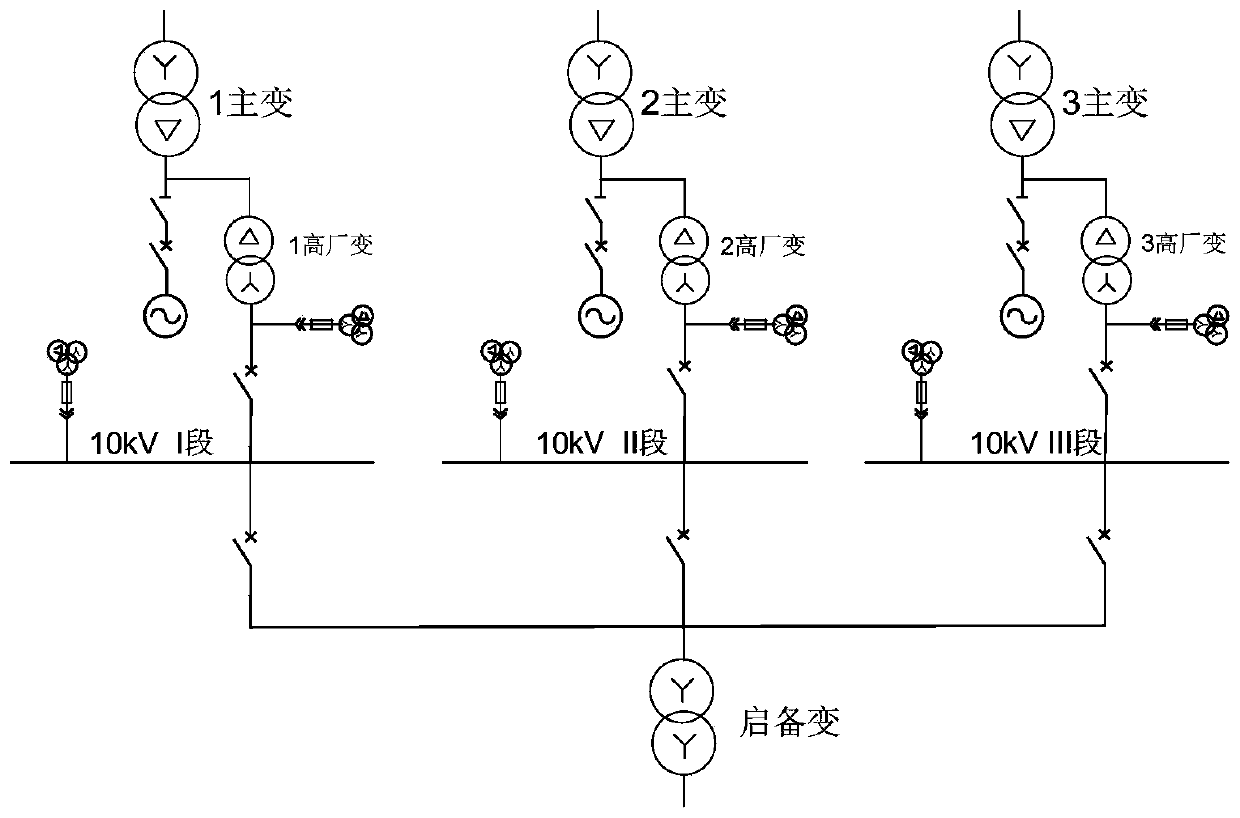

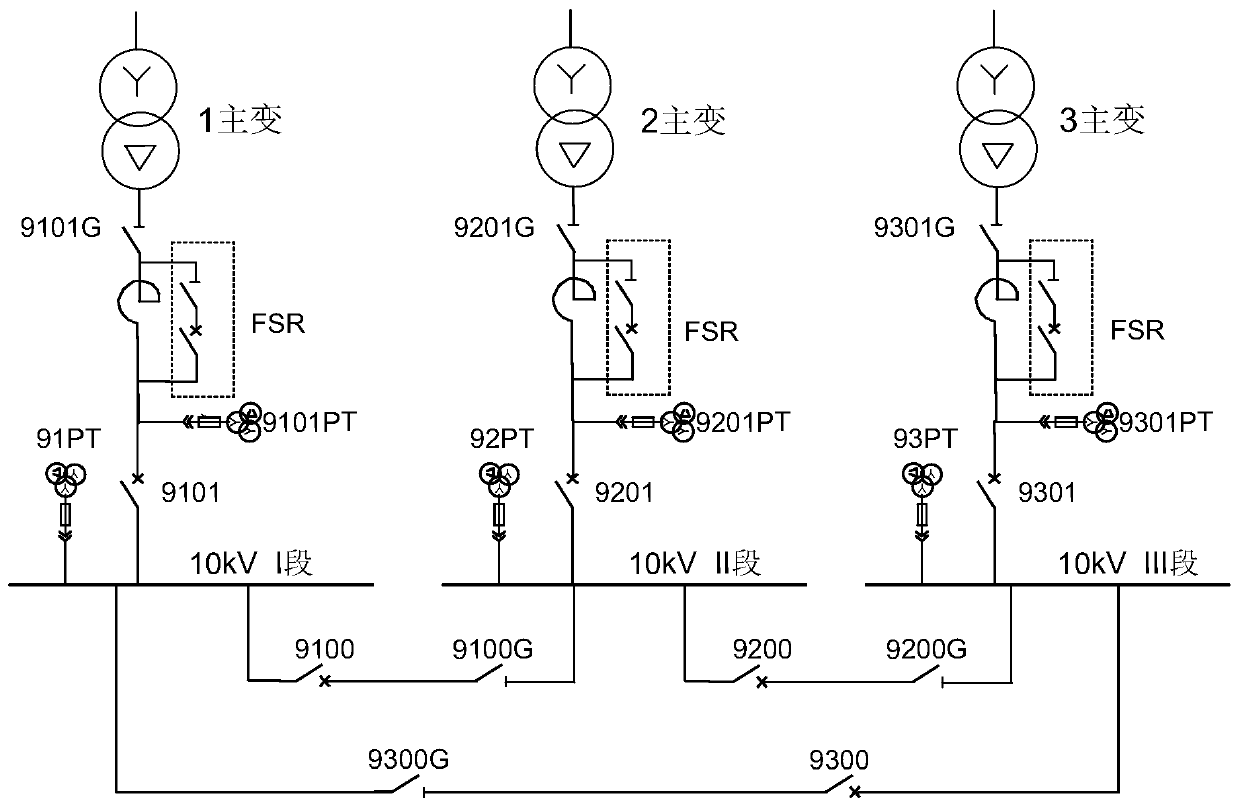

[0031] Such as figure 1 As shown, in the traditional factory power fast switching system, it is necessary to set up a special high-voltage factory transformer to provide the working incoming power, and set up a special start-up and backup transformer to provide the start-up backup power. The booster station or from a dedicated line. Gas-steam combined cycle distributed energy projects usually have centralized equipment layout, a large number of units, and a small footprint; for gas-steam combined cycle distributed energy projects, the traditional factory power fast switching system has the following shortcomings: the fast switching system needs to be set up separately For high-voltage plant transformers, start-up and backup transformers, and closed busbars, the system occupies a large area a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com