Dialkyl urea type supramolecular thickening agent and preparation method and application thereof

A dialkyl urea and thickener technology, which is applied in the preparation of urea derivatives, chemical instruments and methods, and the preparation of organic compounds, etc., can solve the problem of long cross-linking time, impossibility, and limited reservoir sensitivity applications, etc. problems, achieve the effect of no need for post-pressing treatment, anti-settling, and excellent shear recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

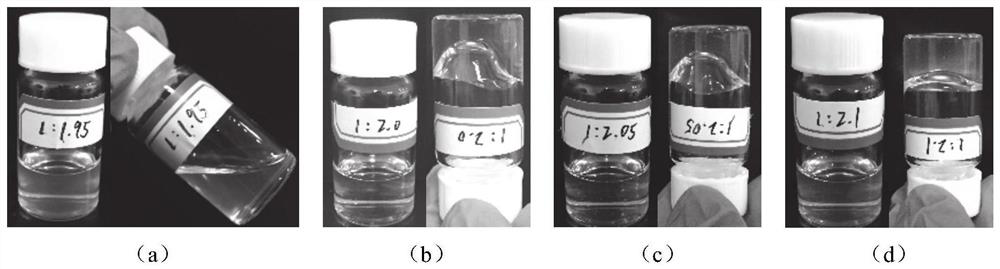

[0064] 2,4-toluene diisocyanate (TDI-100) and 2-ethylhexylamine are reactants, and the reaction molar ratio of 2,4-toluene diisocyanate and 2-ethylhexylamine is 1:2.05. Dissolve in 100mL dichloromethane respectively, slowly add the two into a three-necked flask under magnetic stirring and nitrogen protection, react at room temperature for 2h, distill off the solvent dichloromethane to obtain a paste-like crude product of dialkylurea. The crude product was recrystallized 2-3 times with ethyl acetate as a solvent, and the obtained crystallized product was placed in a vacuum drying oven and dried at 65°C for 12 hours to obtain a white waxy solid, which was the target product dialkylurea thickened The oxidizing agent 2,4-dialkylureidotoluene (2,4-bis(N'-alkylureido)toluene) is referred to as EHUT-100.

[0065] The reaction scheme is as follows:

[0066]

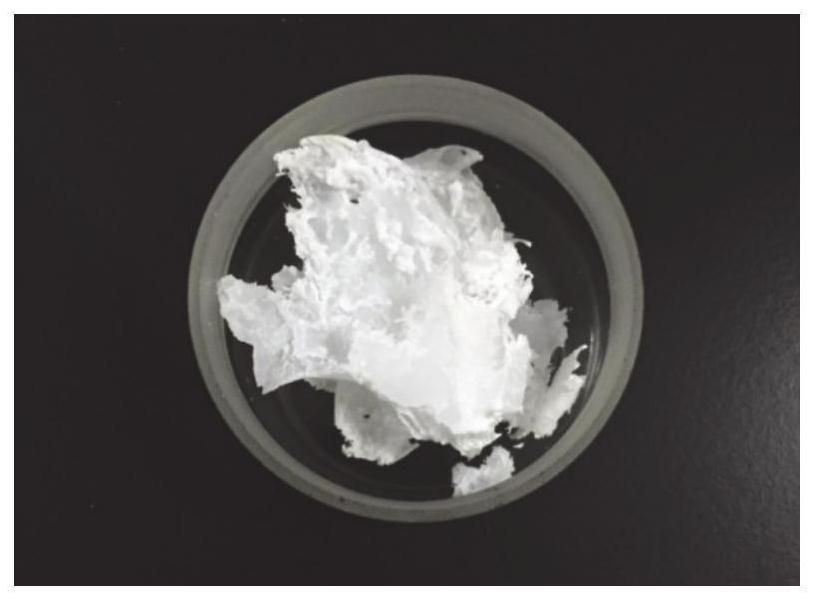

[0067] The obtained 2,4-dialkylureidotoluene as figure 1 As shown, 2,4-dialkylureidotoluene is a white waxy solid.

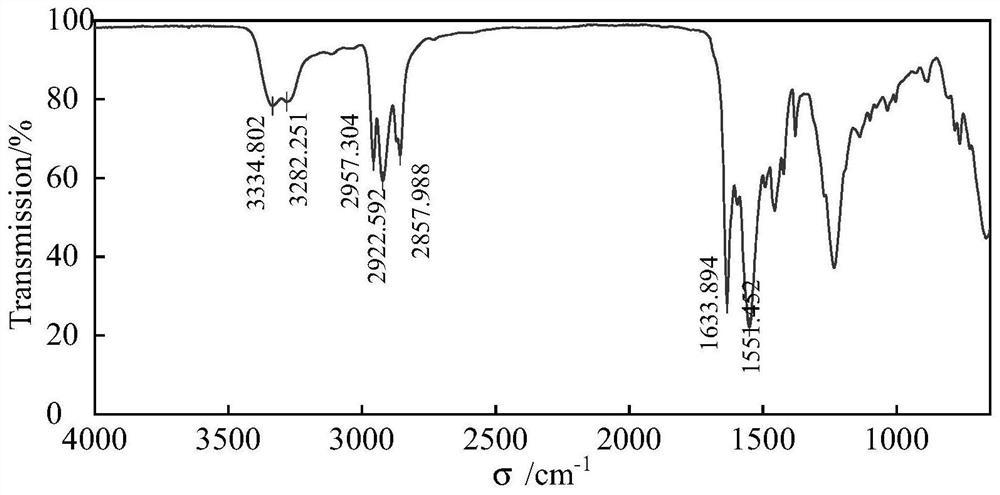

[006...

Embodiment 2

[0070] Compared with Example 1, the difference is that the molar ratio of 2,4-toluene diisocyanate to 2-ethylhexylamine is 1:1.95.

Embodiment 3

[0072] Compared with Example 1, the difference is that the molar ratio of 2,4-toluene diisocyanate to 2-ethylhexylamine is 1:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com