Fluidized vertical type stirring mill suitable for dry type grinding

A fluidization and stirring motor technology, applied in grain processing and other directions, can solve the problems of low powder fineness, uneven particle size distribution, high energy consumption, etc., and achieve low equipment maintenance costs, uniform particle size distribution, and grinding. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

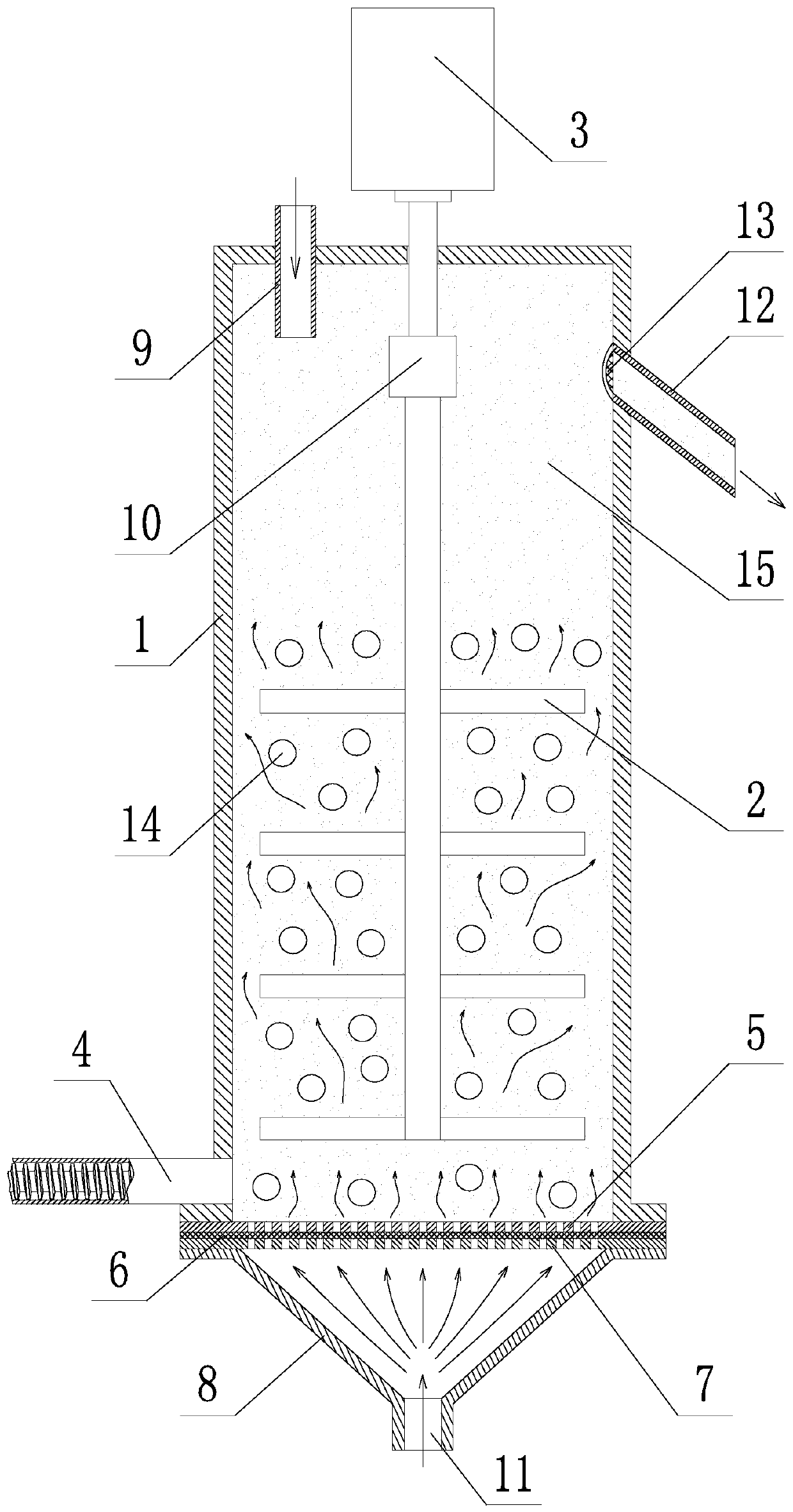

[0014] Such as figure 1 As shown, a fluidized vertical agitated mill suitable for dry grinding, including cylinder 1, agitator 2, agitation motor 3, screw feeder 4, liner 5, ventilation isolation cloth 6, support Plate 7 and base cover 8; the cylinder body 1 is vertically arranged, and the top plate of the cylinder body 1 is provided with a grinding medium feeding inlet 9; the stirring motor 3 is erected vertically above the top plate of the cylinder body 1, and the stirring motor The motor shaft of 3 faces downward and extends to the inside of the cylinder 1; the agitator 2 is located inside the cylinder 1, and the agitator shaft of the agitator 2 and the motor shaft of the agitation motor 3 are coaxially fixed together through a coupling 10; The base cover 8 is sealed and fixed at the mouth of the bottom of the cylinder body 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com