Method for improving mechanical property of segmented copolymer thermoplastic elastomer

A thermoplastic elastomer and block copolymer technology, applied in the field of thermoplastic elastomers, can solve the problems of instant deformation, failure, increase in tensile strength, etc., and achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Mechanical enhancement of equi-quadaxial pre-stretching thermal relaxation based on polystyrene-poly(n-butyl acrylate)-polystyrene (molecular weight: 1.5W-12W-1.5W) triblock thermoplastic elastomer film

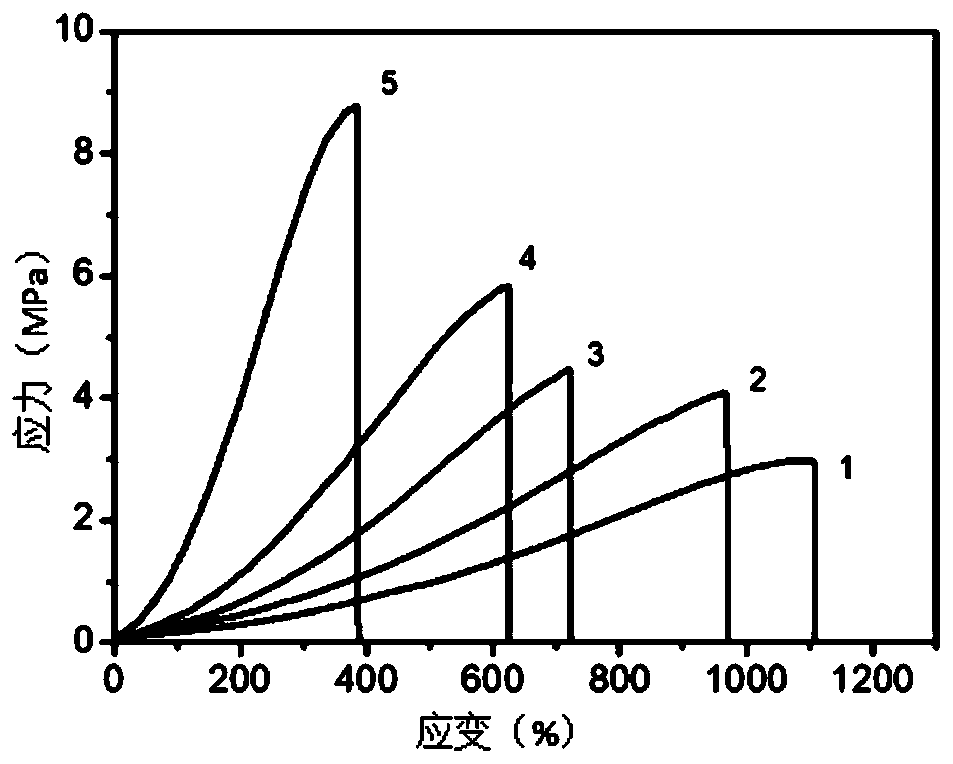

[0021] The polystyrene-poly(n-butyl acrylate)-polystyrene triblock thermoplastic elastomer film is pre-stretched to 1.5 times, 3 times, 6 times, and 12 times the area of the initial film respectively by equal 4-axis; Under stretching conditions, put it in 120°C for 8 hours and then cool it down at room temperature. The mechanical properties of the films obtained before and after pre-stretching thermal relaxation were compared. from figure 1 It can be seen that the greater the degree of pre-stretching of the film, the greater the breaking strength of the film obtained after thermal relaxation; the film whose pre-stretching is about 1.5 times the area of the initial film is thermally relaxed, and the breaking strength is 1.5 times that of the initial film...

Embodiment 2

[0023] Example 2: Biaxial asymmetric pre-stretching (uniaxial pre-stretching) based on polystyrene-polyacrylate n-butyl acrylate-polystyrene (molecular weight: 1.5W-12W-1.5W) tri-block thermoplastic elastomer film ) Mechanical enhancement of thermal relaxation

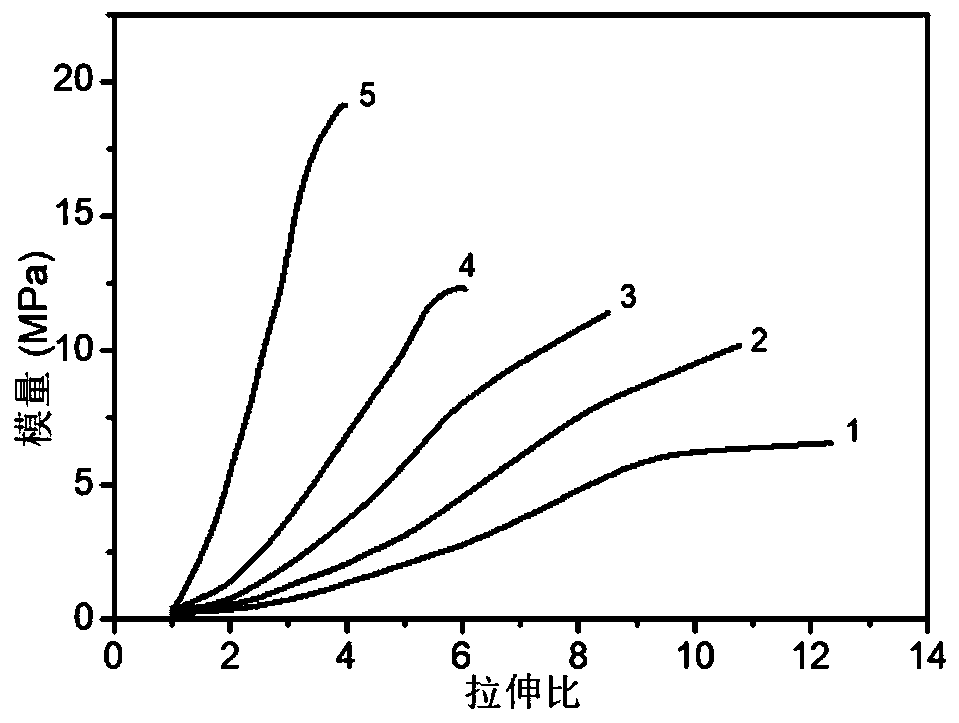

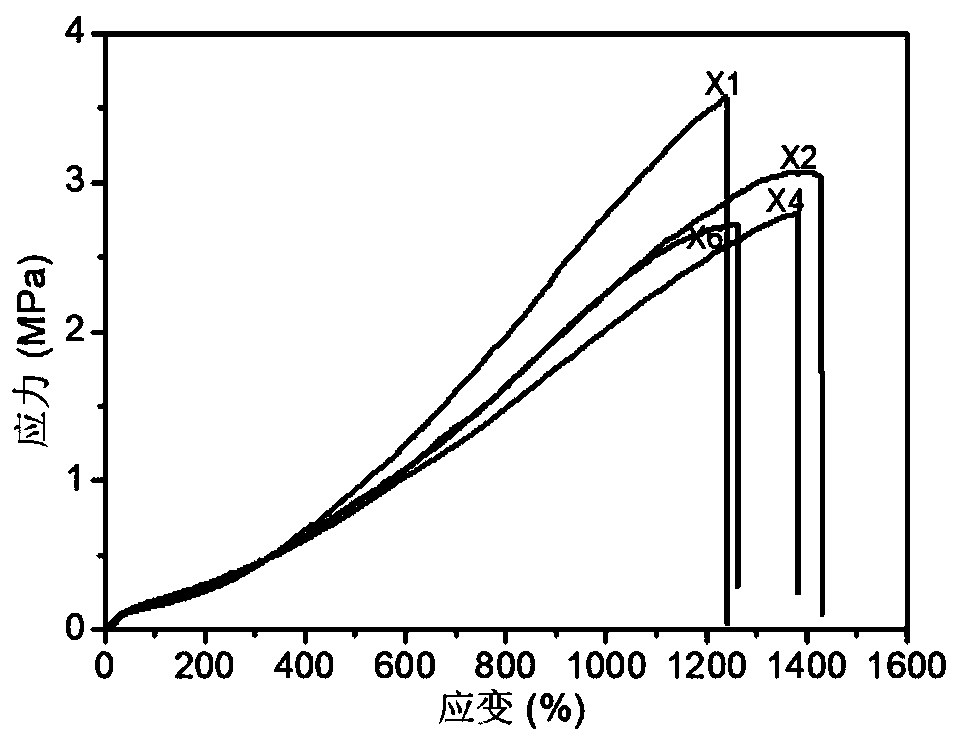

[0024] The polystyrene-poly(n-butyl acrylate)-polystyrene triblock thermoplastic elastomer film is pre-stretched to 2 times, 4 times, and 6 times the length of the initial film respectively by uniaxial; under fixed pre-stretching conditions, Put it in 110°C for 7 hours and then cool it down at room temperature. The mechanical properties of the films obtained before and after pre-stretching thermal relaxation were compared. from image 3 It can be seen that the pre-stretched thermally relaxed films have similar stress-strain curves perpendicular to the stretching direction; from Figure 4 It can be seen that the pre-stretched thermally relaxed films have similar moduli perpendicular to the stretching direction; from ...

Embodiment 3

[0026] Example 3: Pentablock thermoplastic elastomer based on polystyrene-n-butyl polyacrylate-polystyrene-n-butyl polyacrylate-polystyrene (molecular weight: 1.5W-12W-1.5W-12W-1.5W) Mechanical enhancement of biaxially asymmetric pre-stretching thermal relaxation of films The polystyrene-poly(n-butylacrylate)-polystyrene-poly(n-butylacrylate-polystyrene) pentablock thermoplastic elastomer film was biaxially Symmetrical pre-stretching, stretching on one side is 3 times the length of the original film, and stretching on one side is 2 times the length of the original film; under fixed pre-stretching conditions, put it in 120°C for 6 hours and then cool it at room temperature. The mechanical properties of the films obtained before and after pre-stretching thermal relaxation were compared. A film with a larger stretch ratio parallel to the stretching direction has a higher breaking strength and a larger modulus, which is about 2 times the breaking strength of the initial film; a fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com