Submerged membrane assembly

A technology of immersed membrane and membrane unit, which is applied to chemical instruments and methods, special treatment targets, sustainable biological treatment, etc. The effect of reducing land and investment costs, eliminating gas accumulation in pipelines, and simplifying operation management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

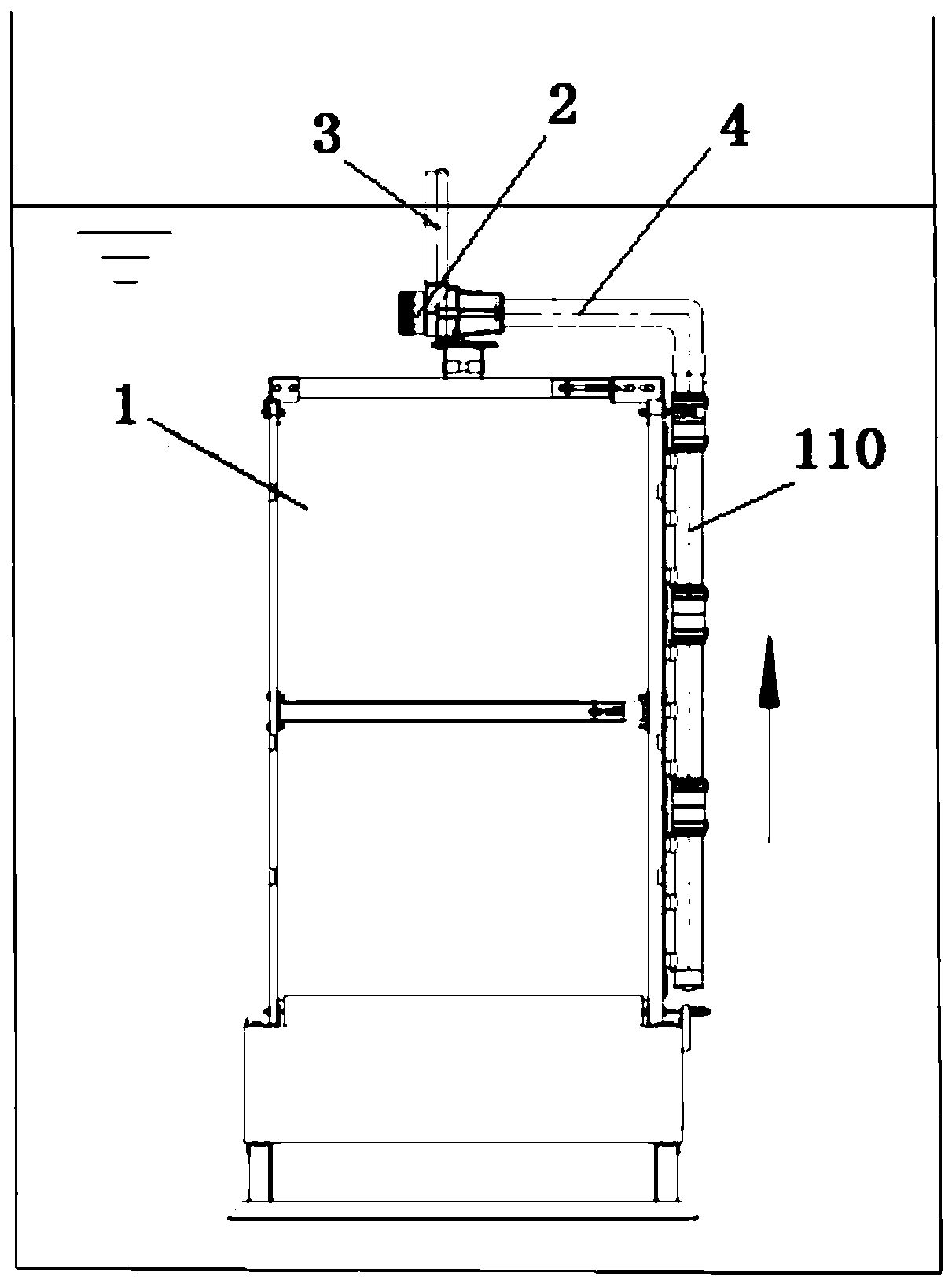

[0027] Such as figure 1 As shown, a submerged membrane unit includes a membrane unit 1, a submersible pump 2 and a second outlet pipe 3. Both the membrane unit 1 and the submersible pump 2 are arranged below the water surface, and the liquid outlet of the membrane unit 1 is connected to the The liquid inlet of the submersible pump 2 is connected. Normally, the larger the water output, the greater the power of the submersible pump 2 is required. One end of the second water outlet pipe 3 is connected to the liquid outlet of the submersible pump 2. The second The other end of the outlet pipe 3 protrudes above the water surface line, and is connected to an external water storage facility or directly discharged.

Embodiment 2

[0029] Such as figure 1 As shown, a submerged membrane unit includes a membrane unit 1, a submersible pump 2 and a second outlet pipe 3. Both the membrane unit 1 and the submersible pump 2 are arranged below the water surface, and the liquid outlet of the membrane unit 1 is connected to the The liquid inlet of the submersible pump 2 is connected. Normally, the larger the water output, the greater the power of the submersible pump 2 is required. One end of the second water outlet pipe 3 is connected to the liquid outlet of the submersible pump 2. The second The other end of the outlet pipe 3 protrudes above the water surface line, and is connected to an external water storage facility or directly discharged.

[0030] Wherein, there is a first water outlet pipe 110 on the membrane module 1, the first water outlet pipe 110 is upward along the side wall of the membrane module 1, and the liquid inlet of the first water outlet pipe 110 is connected with the liquid outlet of the memb...

Embodiment 3

[0032] Such as figure 1 As shown, a submerged membrane unit includes a membrane unit 1, a submersible pump 2 and a second outlet pipe 3. Both the membrane unit 1 and the submersible pump 2 are arranged below the water surface, and the liquid outlet of the membrane unit 1 is connected to the The liquid inlet of the submersible pump 2 is connected. Normally, the larger the water output, the greater the power of the submersible pump 2 is required. One end of the second water outlet pipe 3 is connected to the liquid outlet of the submersible pump 2. The second The other end of the outlet pipe 3 protrudes above the water surface line, and is connected to an external water storage facility or directly discharged.

[0033] Wherein, there is a first water outlet pipe 110 on the membrane module 1, the first water outlet pipe 110 is upward along the side wall of the membrane module 1, and the liquid inlet of the first water outlet pipe 110 is connected with the liquid outlet of the memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com