Solid epoxy plastic plate and producing method thereof

A technology of epoxy plastic and production method, applied in the field of solid epoxy plastic sheet and production, can solve the problems of high price, unfavorable development of the automobile industry, high cost, etc., and achieve the effects of low cost, easy processing and increased toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

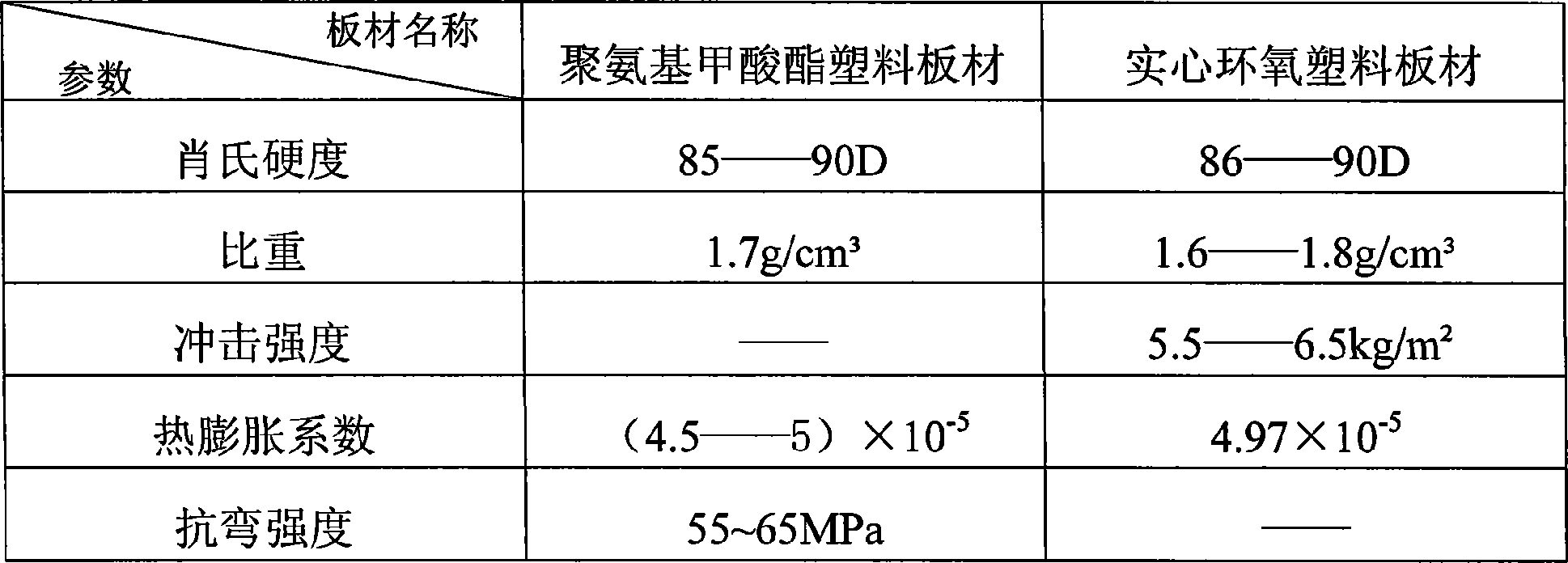

Image

Examples

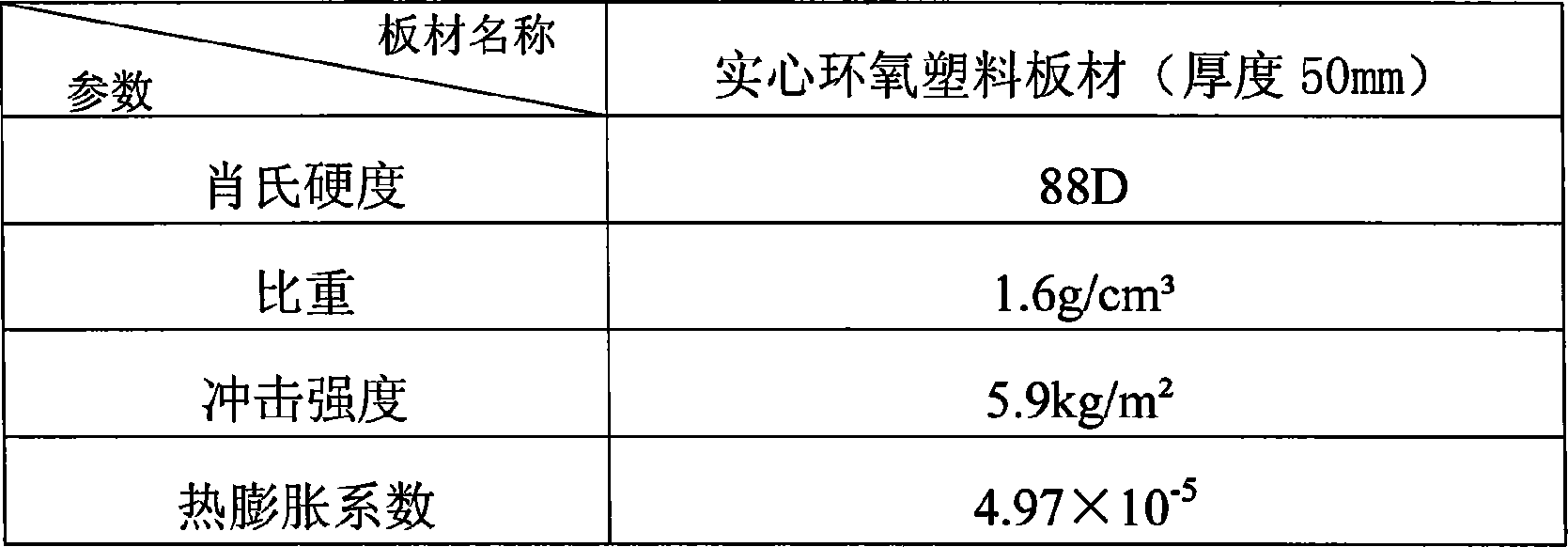

Embodiment 1

[0026] Embodiment 1: The thickness of the formed plate produced this time is 50mm, and the thickness of the formed plate processed each time in actual production is 25mm, so this production is divided into two major steps of primary processing and secondary processing. The raw materials and production methods used in primary processing are as follows:

[0027] Get the following raw materials: 500g epoxy resin, 85g dibutyl phthalate, 500g filler, 115g curing agent, 15g foam breaker, each of the above-mentioned raw materials meets the following requirements respectively: Oxygen resin contains epoxy value of 4.5 equivalents, softening point 18 ℃, volatile matter 0.9%; described dibutyl phthalate, its density is 1.045g / cm 3 , the purity is 99.5%; the filler is TZ-1Mgo.SiO2 filler, and its molecular formula is Mg 3 [Si 4 o 10 ](OH) 2 , the particle size is 400 mesh, and the whiteness is 88; the curing agent is diethylenetriamine-propylene oxide butyl ether adduct, its amine val...

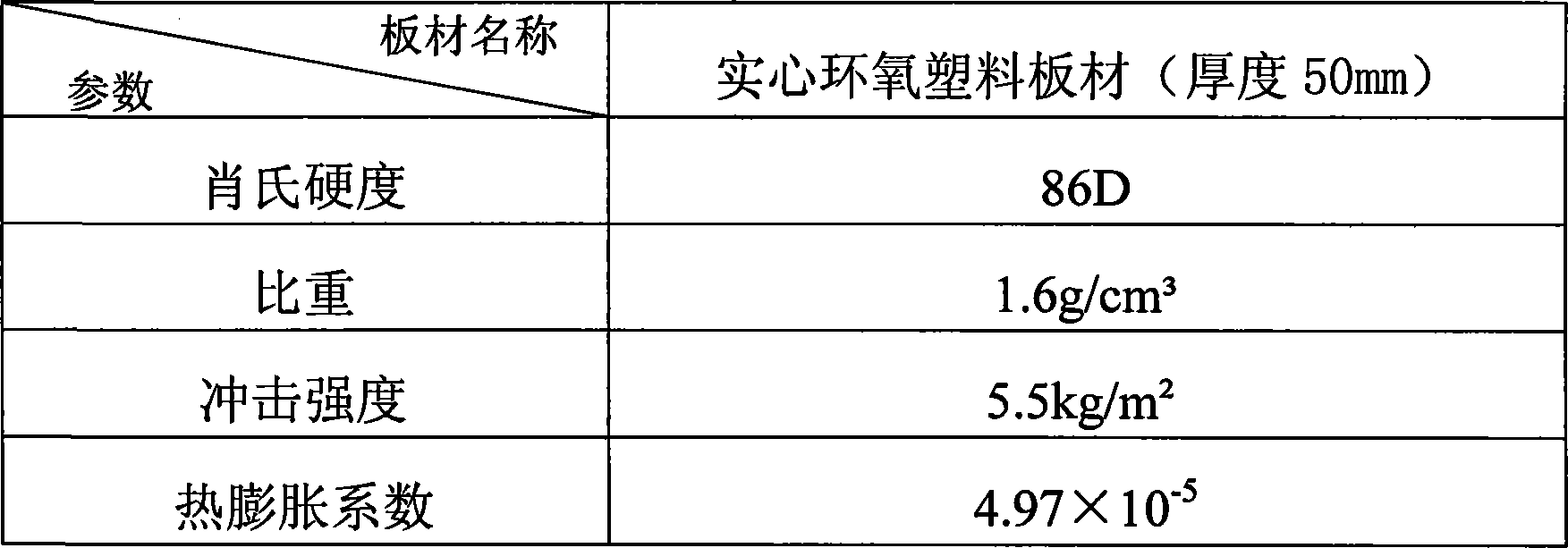

Embodiment 2

[0038] Embodiment 2: The thickness of the formed plate produced this time is 50mm, and the thickness of the formed plate processed each time in actual production is 25mm, so this production is divided into two major steps of primary processing and secondary processing. The raw materials and production methods used in primary processing are as follows:

[0039] Get the following raw materials: 500g epoxy resin, 80g dibutyl phthalate, 450g filler, 115g curing agent, 10g foam breaker, each of the above-mentioned raw materials meets the following requirements respectively: Oxygen resin contains epoxy value of 4.5 equivalents, softening point 18 ℃, volatile matter 0.9%; described dibutyl phthalate, its density is 1.045g / cm 3 , the purity is 99.5%; the filler is TZ-1Mgo.SiO2 filler, and its molecular formula is Mg 3 [Si 4 o 10 ](OH) 2 , the particle size is 400 mesh, and the whiteness is 88; the curing agent is diethylenetriamine-propylene oxide butyl ether adduct, its amine val...

Embodiment 3

[0042]Embodiment 3: The thickness of the formed plate produced this time is 50mm, and the thickness of the formed plate processed each time in actual production is 25mm, so this production is divided into two major steps of primary processing and secondary processing. The raw materials and production methods used in primary processing are as follows:

[0043] Get the following raw materials: 500g epoxy resin, 90g dibutyl phthalate, 550g filler, 120g curing agent, 20g foam breaker, each of the above-mentioned raw materials meets the following requirements respectively: Oxygen resin contains epoxy value of 4.5 equivalents, softening point 18 ℃, volatile matter 0.9%; described dibutyl phthalate, its density is 1.045g / cm 3 , the purity is 99.5%; the filler is TZ-1Mgo.SiO2 filler, and its molecular formula is Mg 3 [Si 4 o 10 ](OH) 2 , the particle size is 400 mesh, and the whiteness is 88; the curing agent is diethylenetriamine-propylene oxide butyl ether adduct, its amine valu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com