Apparatus and method for improving corrosion resistance of magnesium alloy by femtosecond laser shock

A femtosecond laser and corrosion-resistant technology, applied in the direction of metal material coating process, can solve the problems of restricting the application of magnesium alloys, intergranular corrosion of magnesium alloys, pitting stress, etc., to reduce electrochemical reactions and promote grain size. Refinement, small heat-affected zone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

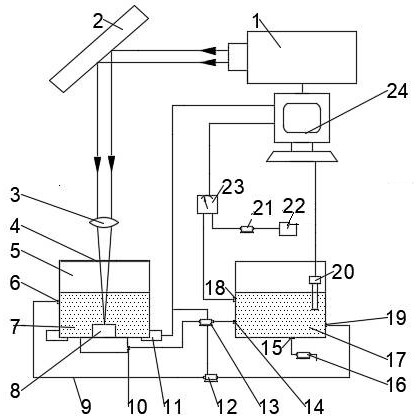

[0019] The details and working conditions of the specific device proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] The inventive device such as figure 1 As shown, it includes femtosecond laser 1, mirror 2, convex lens 3, square window 4, first reaction vessel 5, first water inlet 6, dilute phosphoric acid solution 7, magnesium alloy sample 8, water pipe 9, first water outlet 10. The three-dimensional mobile platform 11, the first electric pump 12, the second electric pump 13, the second water inlet 14, the second water outlet 15, the fourth electric pump 16, the second reaction vessel 17, the fourth water outlet 18, the second Three water outlets 19, a concentration sensor 20, a third electric pump 21, a concentrated phosphoric acid storage tank 22, a flow controller 23, and a computer control system 24. The first reaction vessel 5 and the second reaction vessel 17 form a circulation system through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com