Vertical prestressed steel strand tensioning construction method for box girder bridges

A technology of vertical prestressing and construction methods, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as unsatisfactory construction quality, and achieve good quality control, small vertical prestress loss, and prevent boxes Effect of oblique cracks in beam web

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

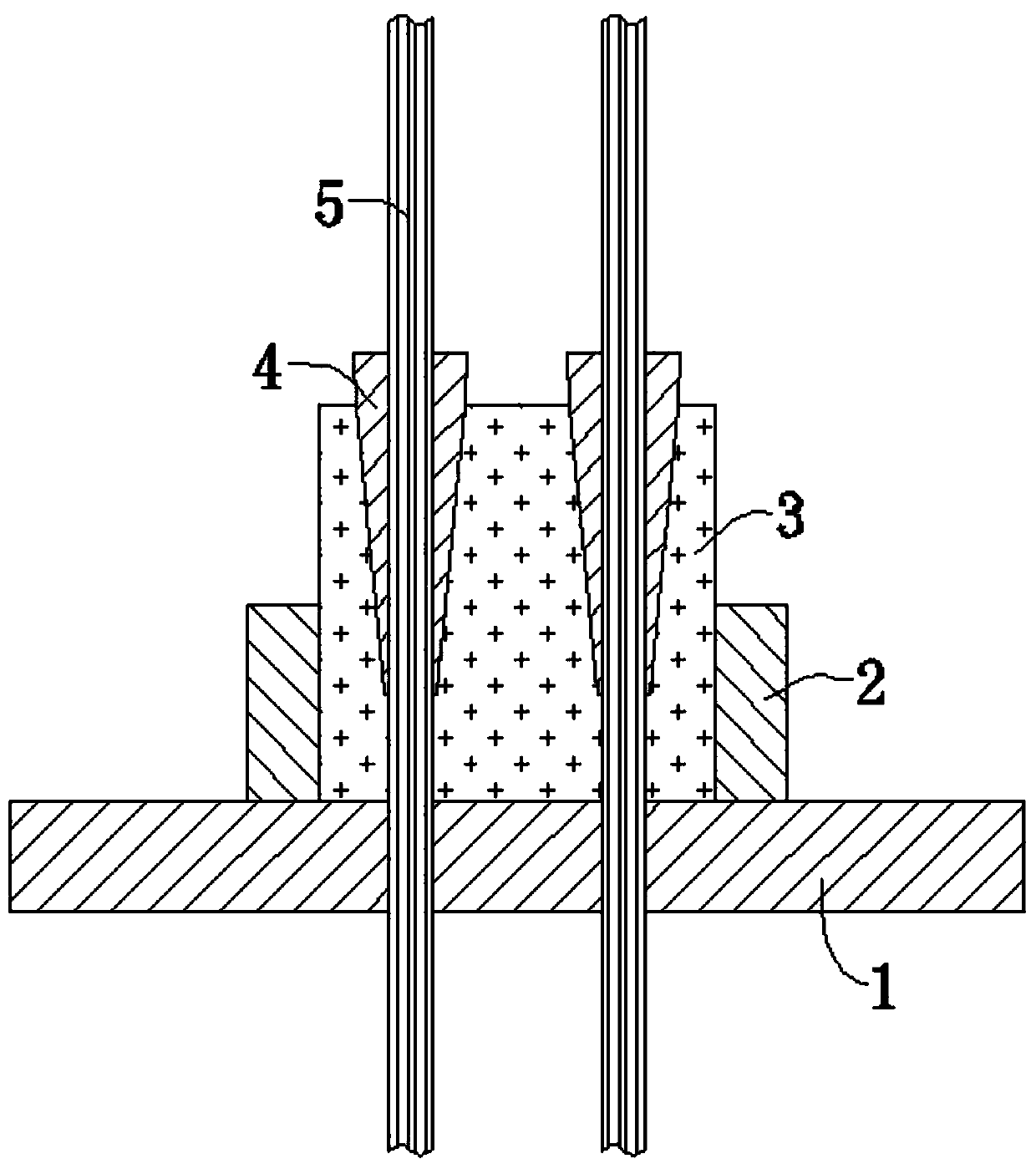

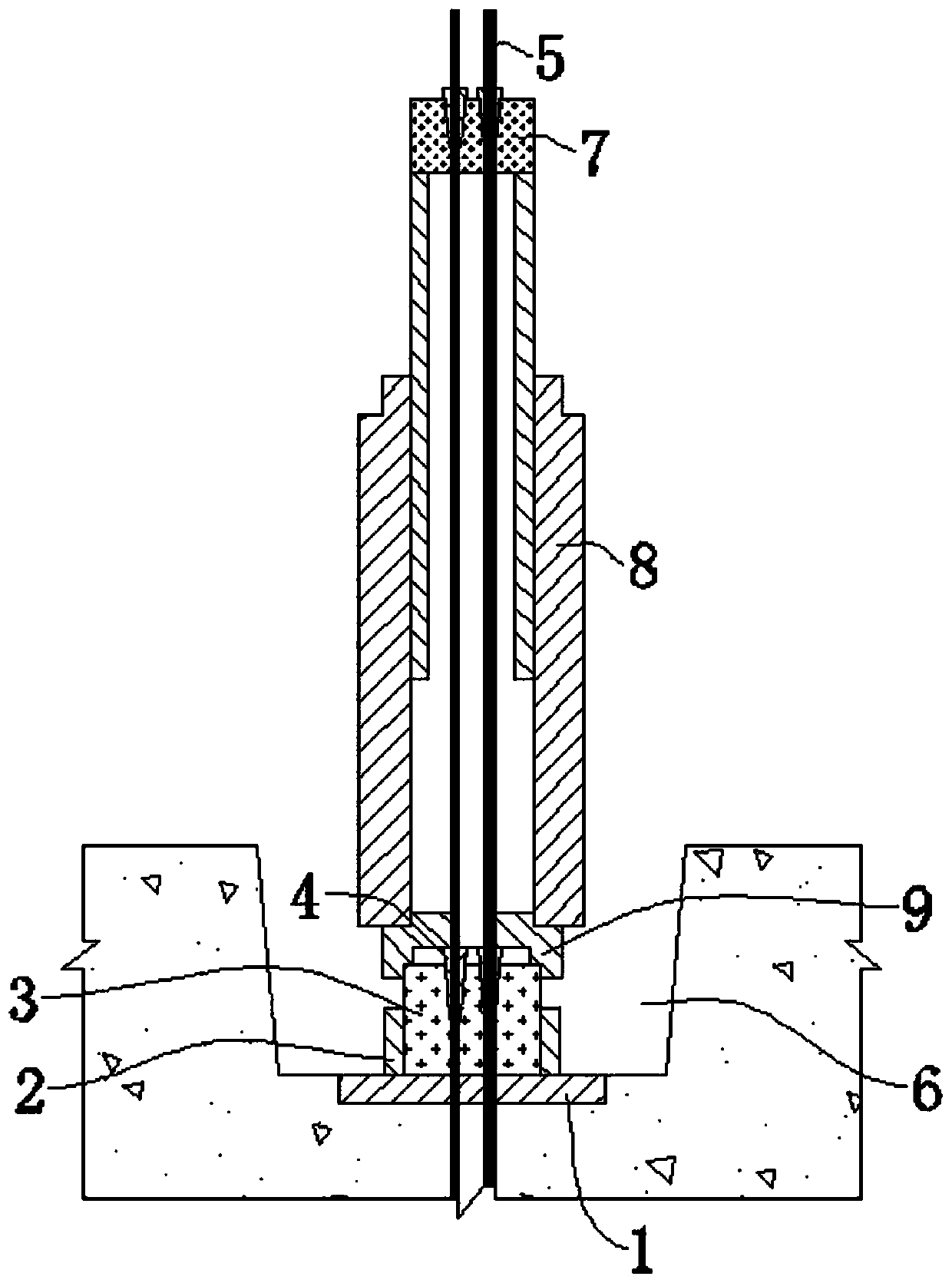

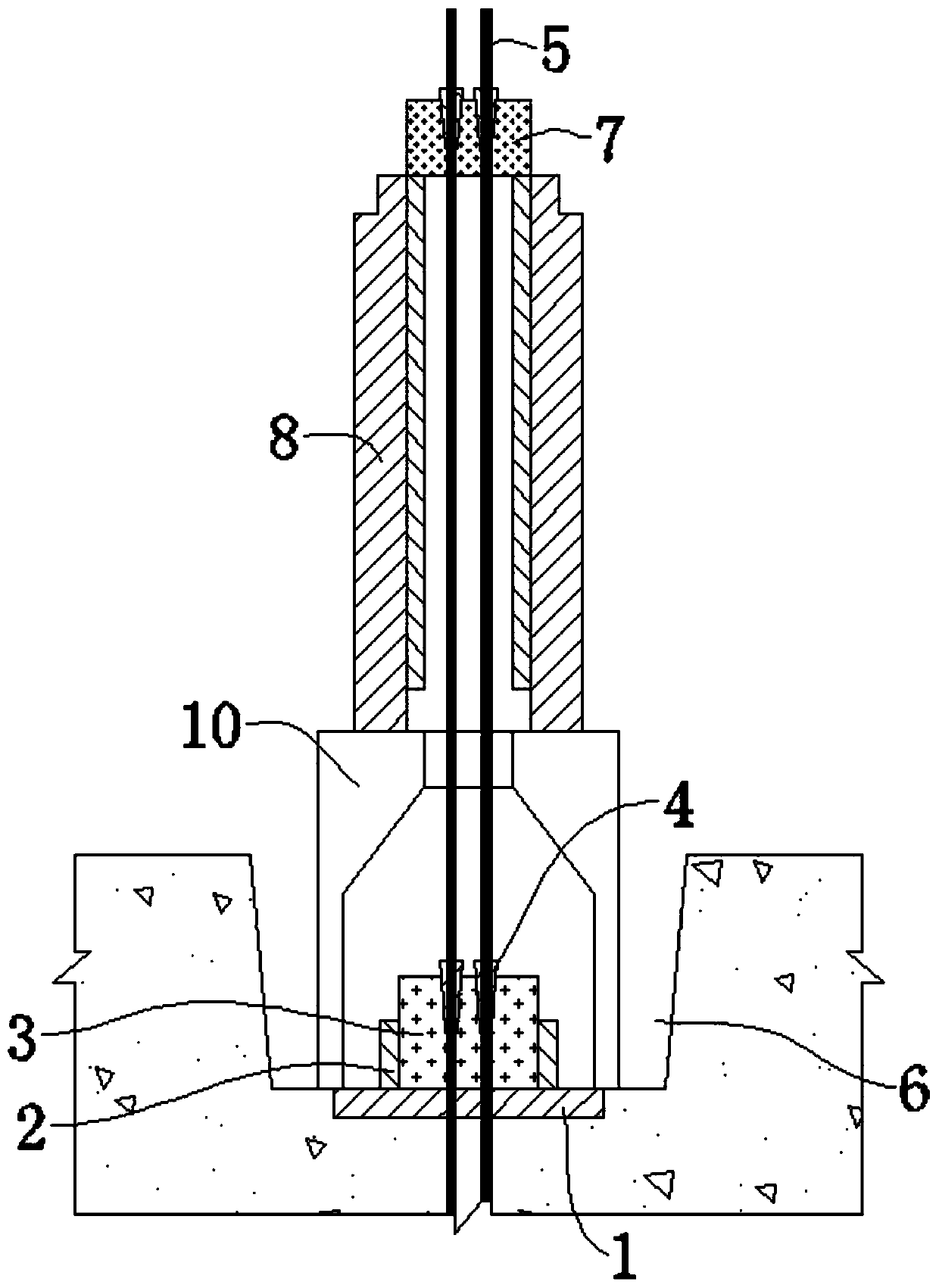

[0042] Embodiment: a kind of vertical prestressed steel strand tensioning construction method of box girder bridge, such as figure 1 , 2 , 3, and 4, including the following steps:

[0043] a. Construction preparation: clean up the debris in the vertical prestressed tensioning slot 6, eliminate the rust and mud on the steel strand 5; install the tensioning anchor cup 3, the tensioning anchor cup 3 and the anchor pad 1 Corresponding positions; check whether the tensioning equipment is normal;

[0044] b. Tensioning for the first time: Install the limit plate 9, the through-hole jack 8, the tool anchor 7 and the tool clip 4 in sequence, and then install the steel strand 5 as a whole according to the process 0→0.1σ con →1.05σ con →Hold the load for 2min→Anchor for tensioning;

[0045] During the stretching process, measure 0.1σ respectively con with 1.05σ con , the jack 8 piston extension value and the tool clip 4 exposed height, and calculate the first tension measured elonga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com