Inner dump type strip mine pit bottom reservoir segmented construction method

A technology for open-pit mines and reservoirs, applied in construction, excavation, water conservancy projects, etc., can solve problems such as low resource utilization, achieve the effects of reducing water storage losses, avoiding production costs, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

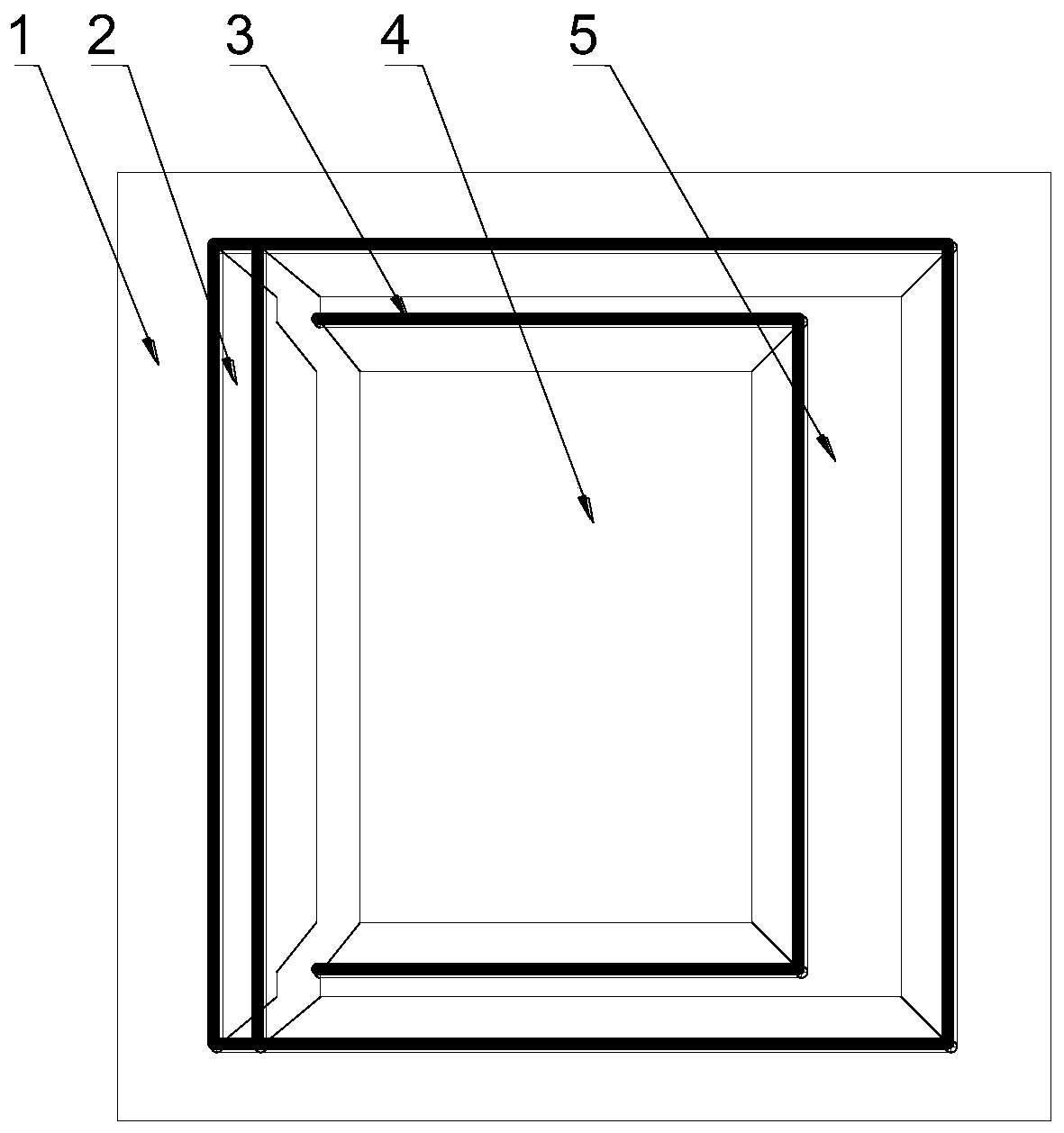

[0029] Such as figure 1 As shown, a method for segmented construction of internal drainage open-pit bottom reservoirs, including single reservoir construction, multi-reservoir segmental construction and water resource storage procedures, the specific steps are as follows:

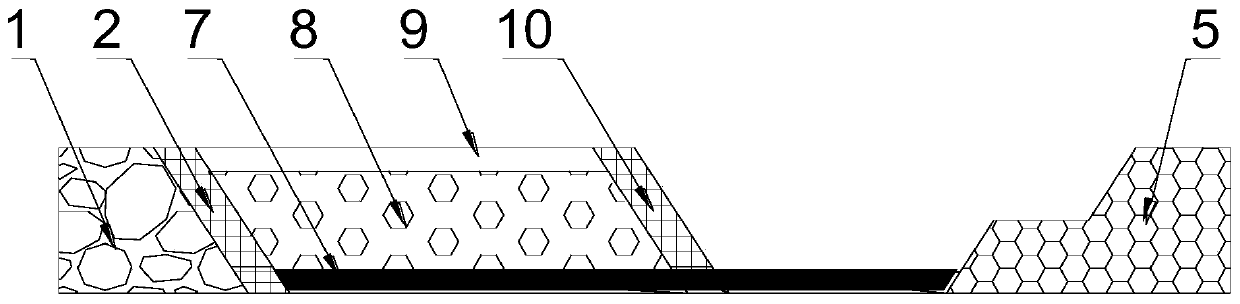

[0030] S1: Side side treatment, that is, when the width of the pit bottom 4 of the open-pit mine reaches about 150-300m, the clay is discharged at the bottom step of the dump site 1 in the open-pit mine, and the thickness of the clay is 5-10m, forming an internal discharge After the isolation layer 2 of the soil dump and the isolation layer 2 of the inner dump site are formed, the advancement of the dump site 1 in the open-pit mine stops.

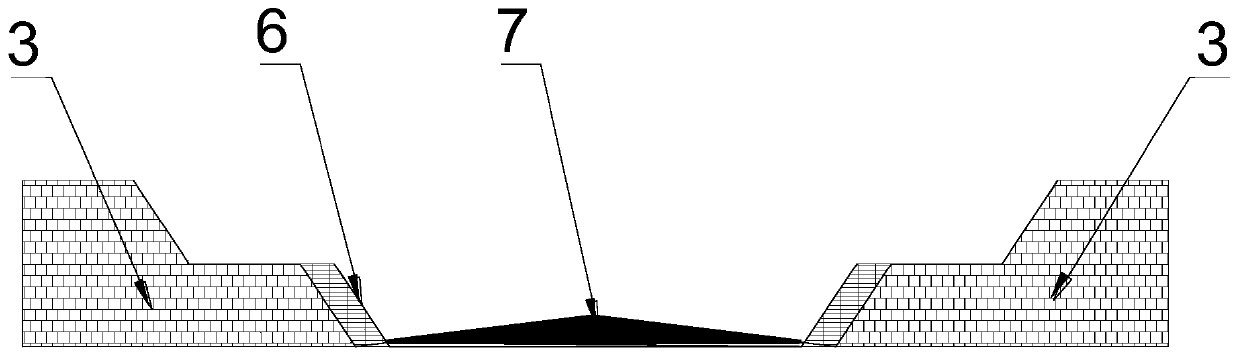

[0031] S2: After the side wall treatment, the concrete is discharged to the slope surface of the bottom step 3 of the side walls on both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com