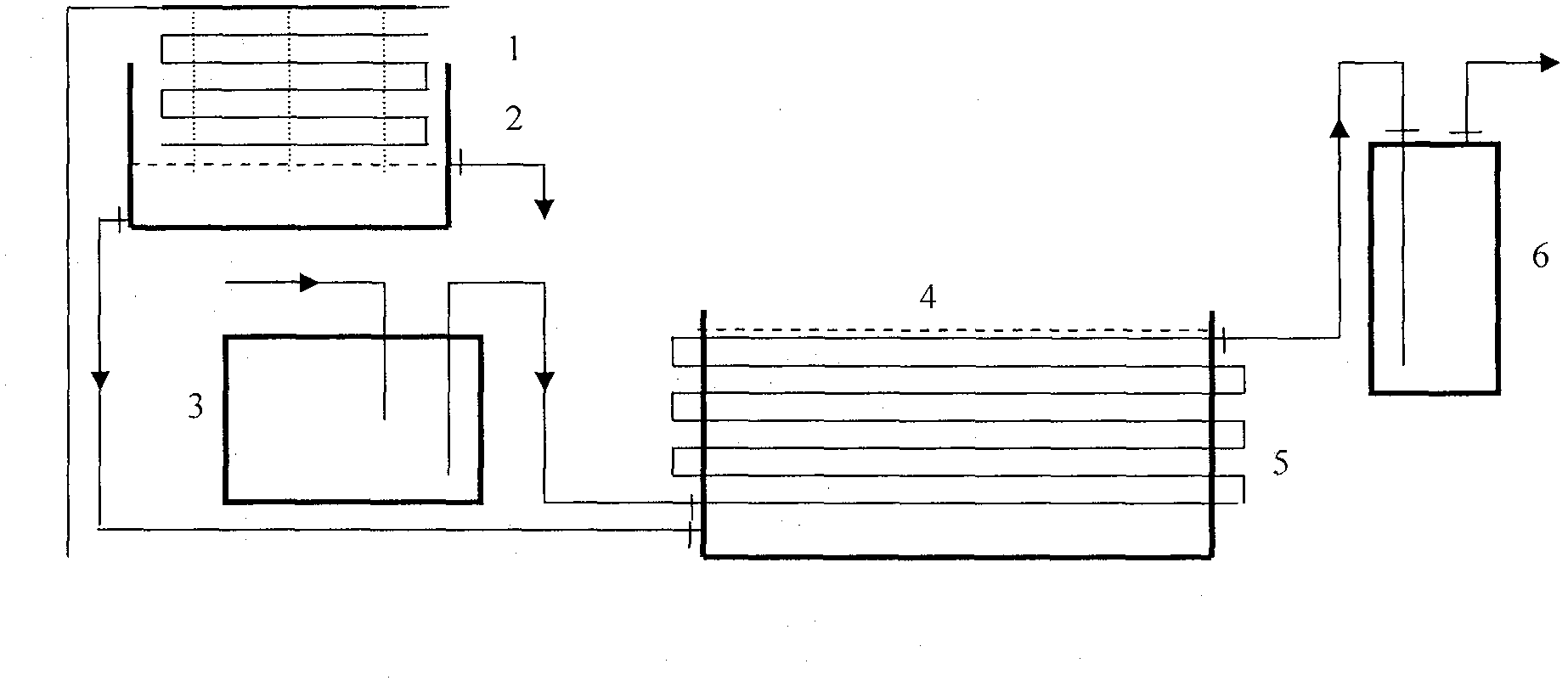

New method for liquid chlorine vaporization

A new method, liquid chlorine technology, applied in the method of container discharge, gas/liquid distribution and storage, and equipment discharged from pressure vessels, etc., can solve the problems of adverse effects on the production site environment, difficult to control temperature, large steam, etc. , to achieve the effect of significant energy saving and emission reduction, sufficient vaporization, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Turn on the water inlet valve and water outlet valve of the vaporized water (the circulating cooling water of the condenser in the phosphorus trichloride workshop) on the liquid chlorine vaporization tank in turn, and check that the inlet water temperature is 20-35°C.

[0025] 2. Slowly open the liquid phase outlet valve on the liquid chlorine storage tank, and then slowly open the liquid chlorine inlet valve on the vaporization tank to introduce liquid chlorine into the vaporization system. At the same time, carefully check the pipes, valves, flanges, etc. to ensure no leakage .

[0026] 3. When the pressure of the vaporization discharge pipe reaches 0.2Mpa, open the chlorine gas outlet valve of the vaporization system and the chlorine gas inlet valve of the chlorine gas buffer tank in sequence, and then guide the vaporized chlorine gas into the chlorine gas buffer tank.

[0027] 4. When the pressure of the chlorine buffer tank reaches 0.4Mpa, open the chlorine valv...

Embodiment 2

[0030] 1. Turn on the water inlet valve and water outlet valve of the vaporized water (the circulating cooling water of the condenser in the phosphorus oxychloride workshop) on the liquid chlorine vaporization tank in turn, and check that the inlet water temperature is 20-35°C.

[0031] 2. Slowly open the liquid phase outlet valve on the liquid chlorine storage tank, and then slowly open the liquid chlorine inlet valve on the vaporization tank to introduce liquid chlorine into the vaporization system. At the same time, carefully check the pipes, valves, flanges, etc. to ensure no leakage .

[0032] 3. When the pressure of the vaporization discharge pipe reaches 0.2Mpa, open the chlorine gas outlet valve of the vaporization system and the chlorine gas inlet valve of the chlorine gas buffer tank in sequence, and then guide the vaporized chlorine gas into the chlorine gas buffer tank.

[0033] 4. When the pressure of the chlorine buffer tank reaches 0.4Mpa, open the chlorine valv...

Embodiment 3

[0036] 1. Turn on the water inlet valve and water outlet valve of the vaporized water (the circulating cooling water of the condenser in the phosphorus trichloride workshop) on the liquid chlorine vaporization tank in turn, and check that the inlet water temperature is 20-35°C.

[0037] 2. Slowly open the liquid phase outlet valve on the liquid chlorine storage tank, and then slowly open the liquid chlorine inlet valve on the vaporization tank to introduce liquid chlorine into the vaporization system. At the same time, carefully check the pipes and valves, flanges, etc. to ensure that there are no leaks.

[0038] 3. When the pressure of the vaporization discharge pipe reaches 0.2Mpa, open the chlorine gas outlet valve of the vaporization system and the chlorine gas inlet valve of the chlorine gas buffer tank in sequence, and then guide the vaporized chlorine gas into the chlorine gas buffer tank.

[0039] 4. When the pressure of the chlorine buffer tank reaches 0.4Mpa, open th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com