Vertical automatic wall brick attaching device used for building construction

A building construction and vertical technology, which can be used in construction, building construction, clay preparation devices, etc., can solve the problems of increasing work risk, increasing construction budget, and lengthening construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is realized through the following technical solutions:

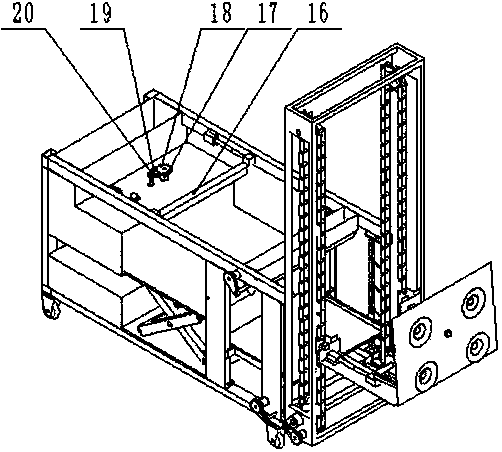

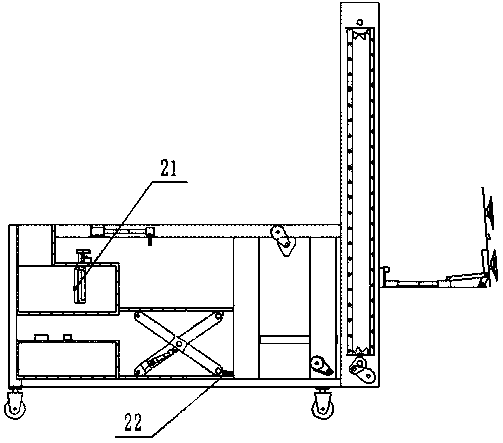

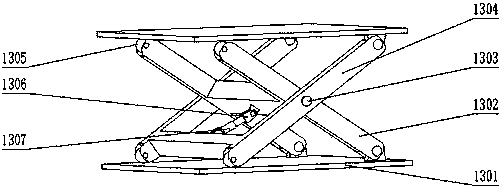

[0026]A vertical automatic wall tile installation for building construction, comprising a hydraulic tile backing device 1, a chain lifting device 2, a feeding device 3, a second motor 4, a second motor belt 5, a second motor pulley 6, Cement pump machine 7, concrete mixing box 8, hydraulic oil pump 9, vacuum pump 10, hydraulic oil tank 11, universal wheel 12, wall brick warehouse lifting device 13, outer load-bearing frame 14, two linkage screw lifting device 15, the first Brick pushing device 16, the fourth motor 17, the fourth motor pulley 18, the fourth motor belt 19, agitator shaft pulley 20, agitator 21, the second brick pushing device 22 and gear box device 23, the hydraulic paste The brick supporting plate device 1 is fixedly connected with the chain lifting device 2 through the connecting plate, and the chain lifting device 2 is fixedly connected with the front end surface of the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com