Imaging logging short section structure based on rotary guiding and rotary guiding well drilling device

A rotary steering, imaging logging technology, applied in directional drilling, drilling equipment, wellbore/well components, etc., can solve the problems of single function, weakened formation evaluation function, lag in formation measurement parameters, etc., to achieve accurate measurement accuracy and shortened time. The effect of accurate assembly length and measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

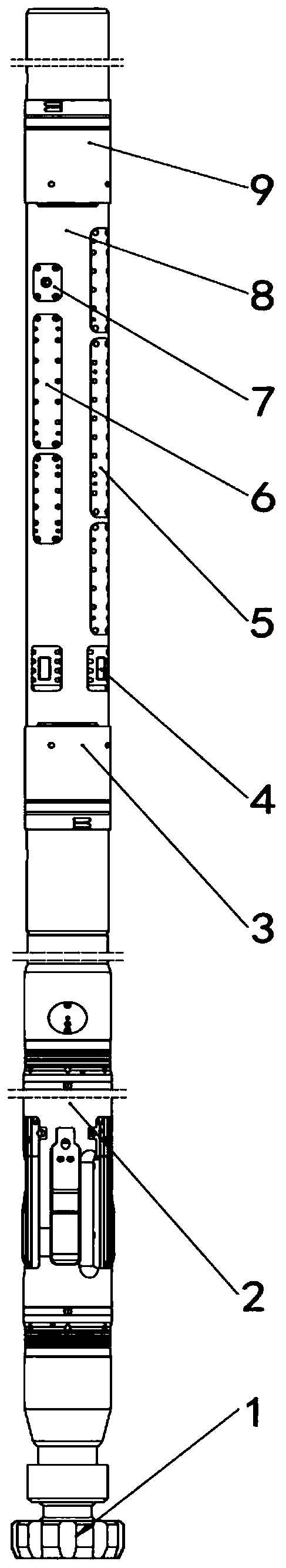

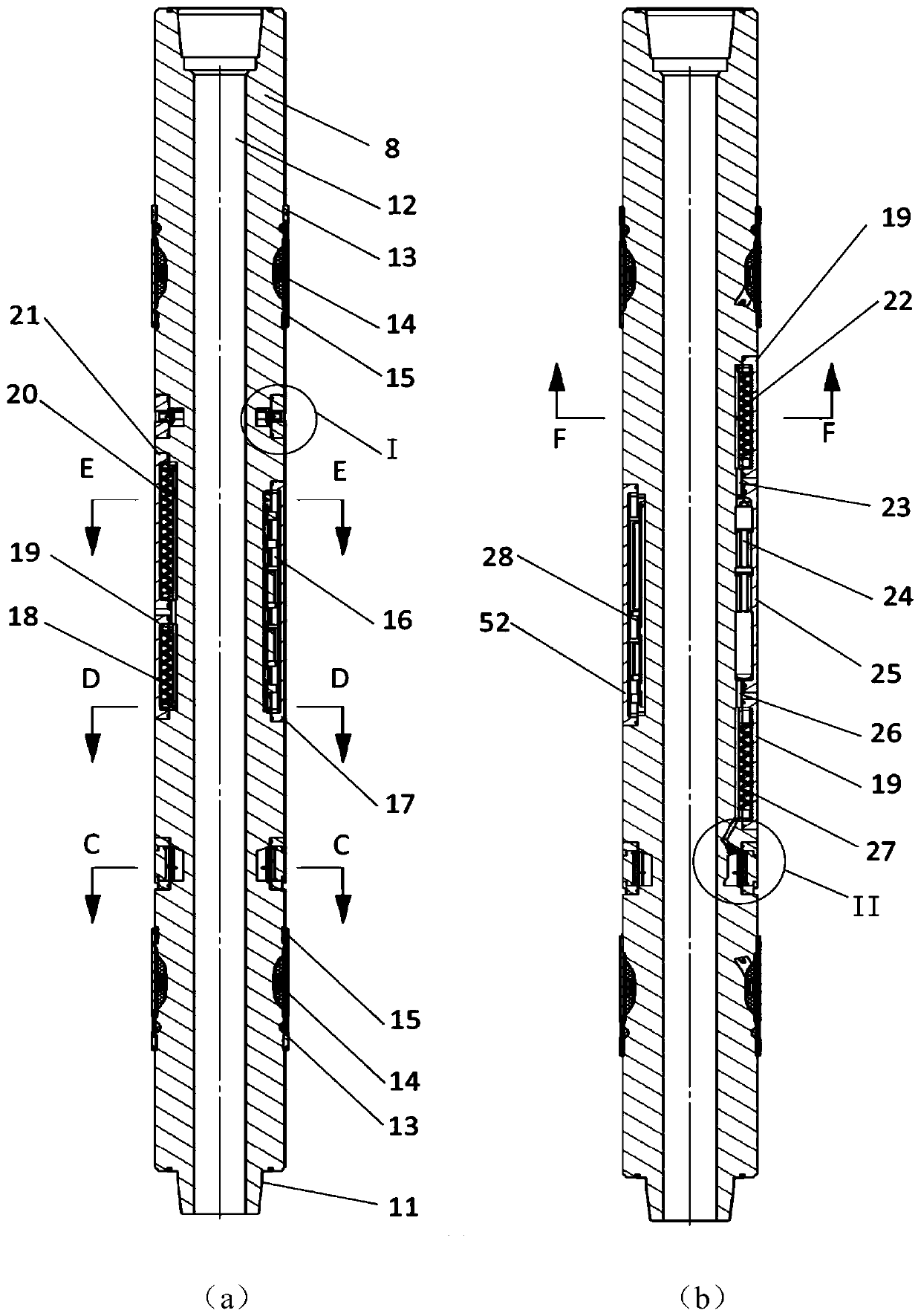

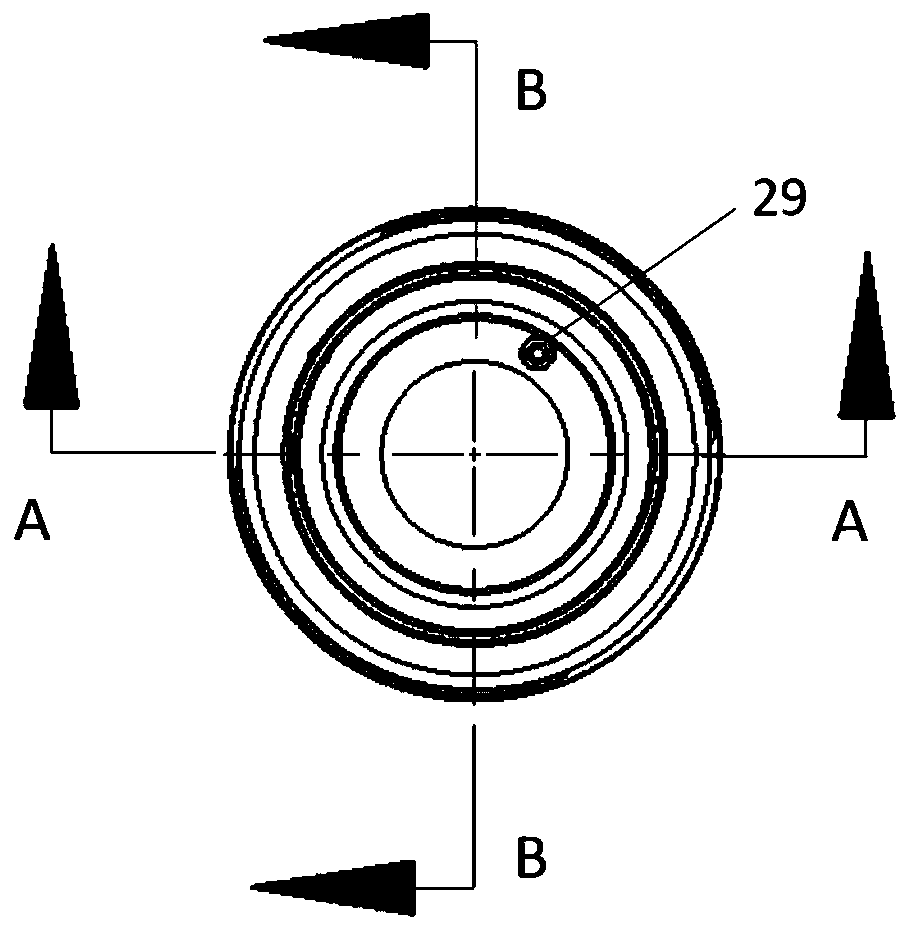

[0035] refer to figure 1 , the present invention is based on the rotary steerable imaging logging nipple structure, including a drill collar body 8, on which a resistivity transmitting antenna assembly 9, a button electrode assembly 7, and a resistivity receiving electrode are sequentially arranged on the drill collar body 8 from top to bottom. The plate assembly 4 and the resistivity receiving antenna assembly 3 are also provided with a gamma imaging detector assembly 5 and a downhole control circuit assembly 6 on the drill collar body 8 .

[0036] The resistivity transmitting antenna assembly 9 is used to transmit the constant current required to detect downhole signals, and the current is transmitted to the formation through the drill collar body 8 . The button electrode assembly 7 is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com