Liquid nitrogen decompression low-temperature cooling system

A cooling system, liquid nitrogen technology, applied in refrigerators, refrigeration and liquefaction, machines using refrigerant evaporation, etc., can solve problems such as boiling and low temperature in the first stage of compressors, so as to increase inlet temperature, improve performance, Effect of reducing the risk of deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

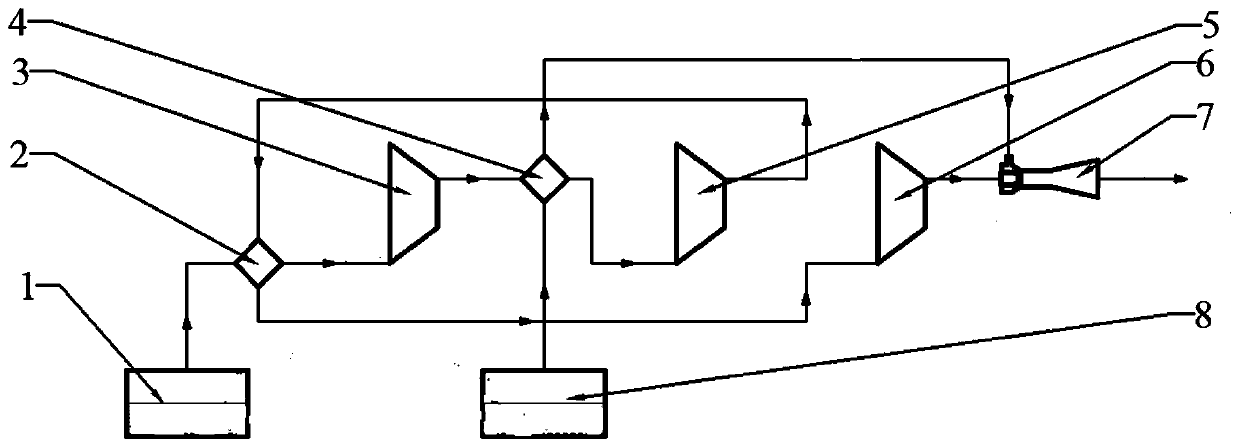

[0032] like figure 1 As shown, the liquid nitrogen decompression and low temperature cooling system provided in this embodiment includes a negative pressure liquid nitrogen storage tank 1, a first heat exchanger 2, a first centrifugal compressor 3, a second heat exchanger 4, a second centrifugal compressor The machine 5, the third centrifugal compressor 6, the gas injector 7, the normal pressure liquid nitrogen storage tank 8 and the pipeline, all components are connected through the pipeline to form a gas path.

[0033]The first centrifugal compressor 3 , the second centrifugal compressor 5 and the third centrifugal compressor 6 respectively constitute the first stage, the second stage and the third stage of the centrifugal compressor assembly.

[0034] Both the first heat exchanger 2 and the second heat exchanger 4 adopt a multi-channel structure, and the gas outlet of the negative pressure liquid nitrogen storage tank 1 communicates with the gas inlet of the first centrifug...

Embodiment 2

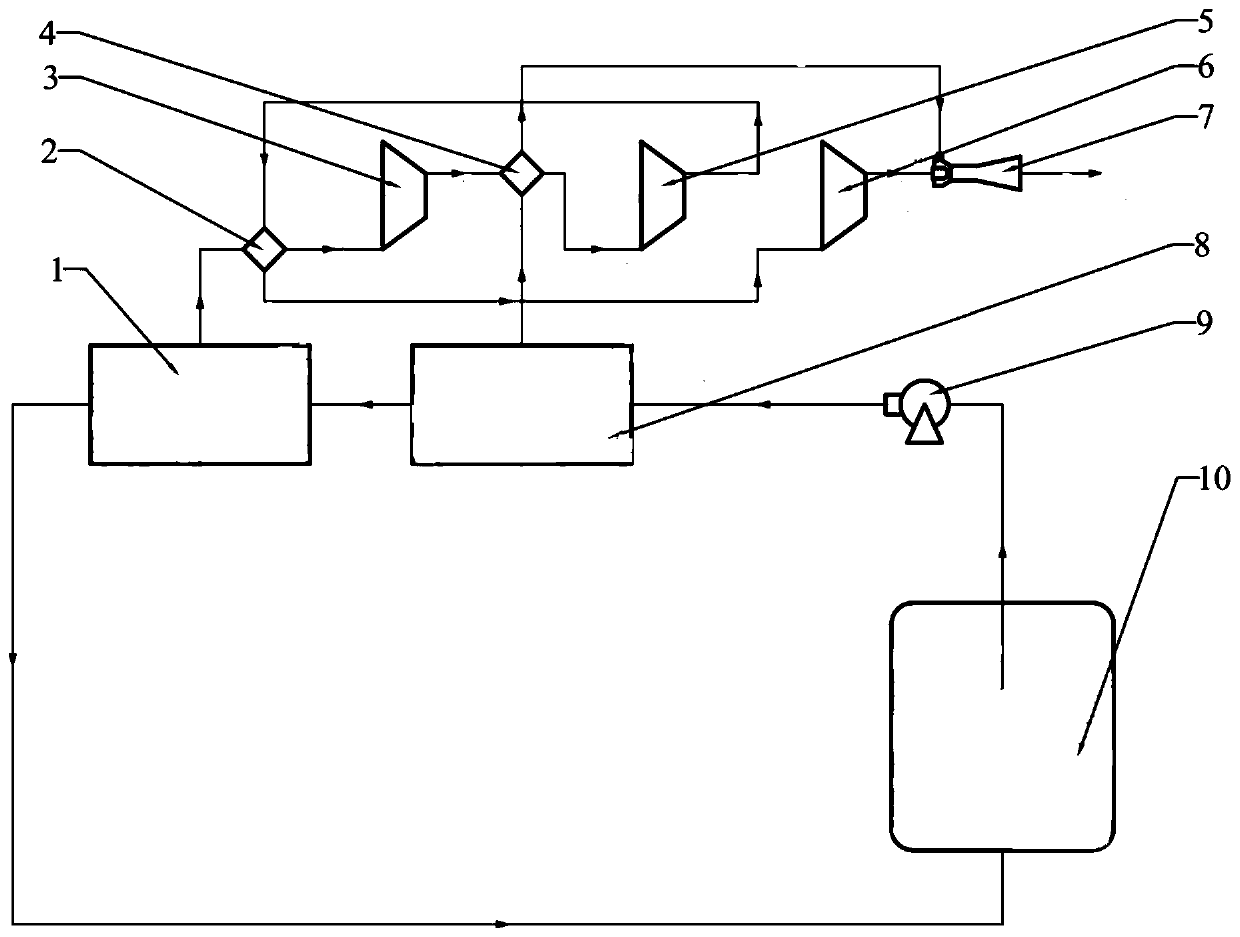

[0037] In this embodiment, the liquid nitrogen depressurization and cryogenic cooling system in Embodiment 1 is used to supercool the atmospheric pressure liquid oxygen.

[0038] like figure 2 As shown, on the basis of Embodiment 1, this embodiment adds a liquid oxygen storage tank 10 and a liquid oxygen pump 9, and uses the liquid nitrogen cooled by the present invention to supercool the liquid oxygen at atmospheric pressure. The atmospheric pressure liquid oxygen in the liquid oxygen storage tank 10 has a temperature of 90K and is extracted from the upper layer of the liquid oxygen storage tank 10 under the action of the liquid oxygen pump 9 . The liquid oxygen after passing through the liquid oxygen pump 9 passes through the heat exchanger in the normal pressure liquid nitrogen storage tank 8 at first, the liquid nitrogen pressure of the normal pressure liquid nitrogen storage tank 8 is 0.101MPa, and the temperature is 77K. In this heat exchanger, liquid oxygen flows on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com