Exploding foil overpressure chip integrating one-shot switch, and detonating device thereof

A trigger switch and explosive foil technology, which is applied in the direction of blasting barrels, offensive equipment, weapon accessories, etc., can solve the problems of low efficiency, high energy consumption, and high price, and achieve the effect of reducing the process flow, reducing the detonating device, and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

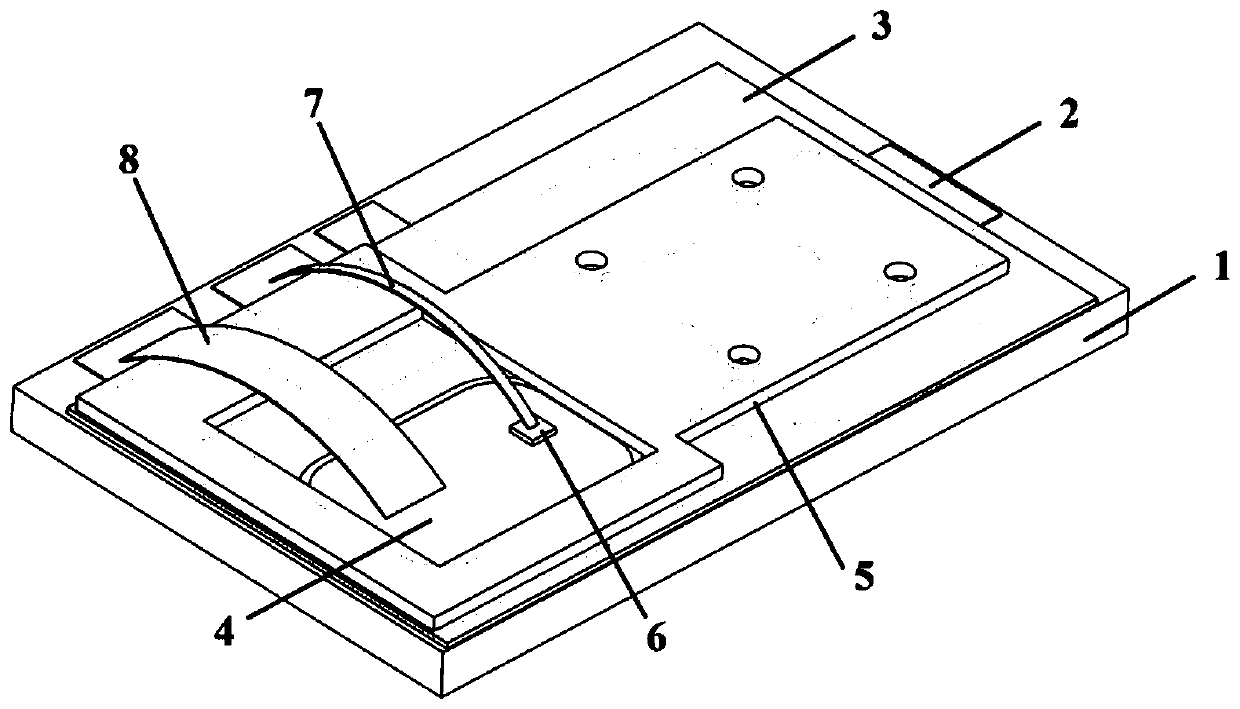

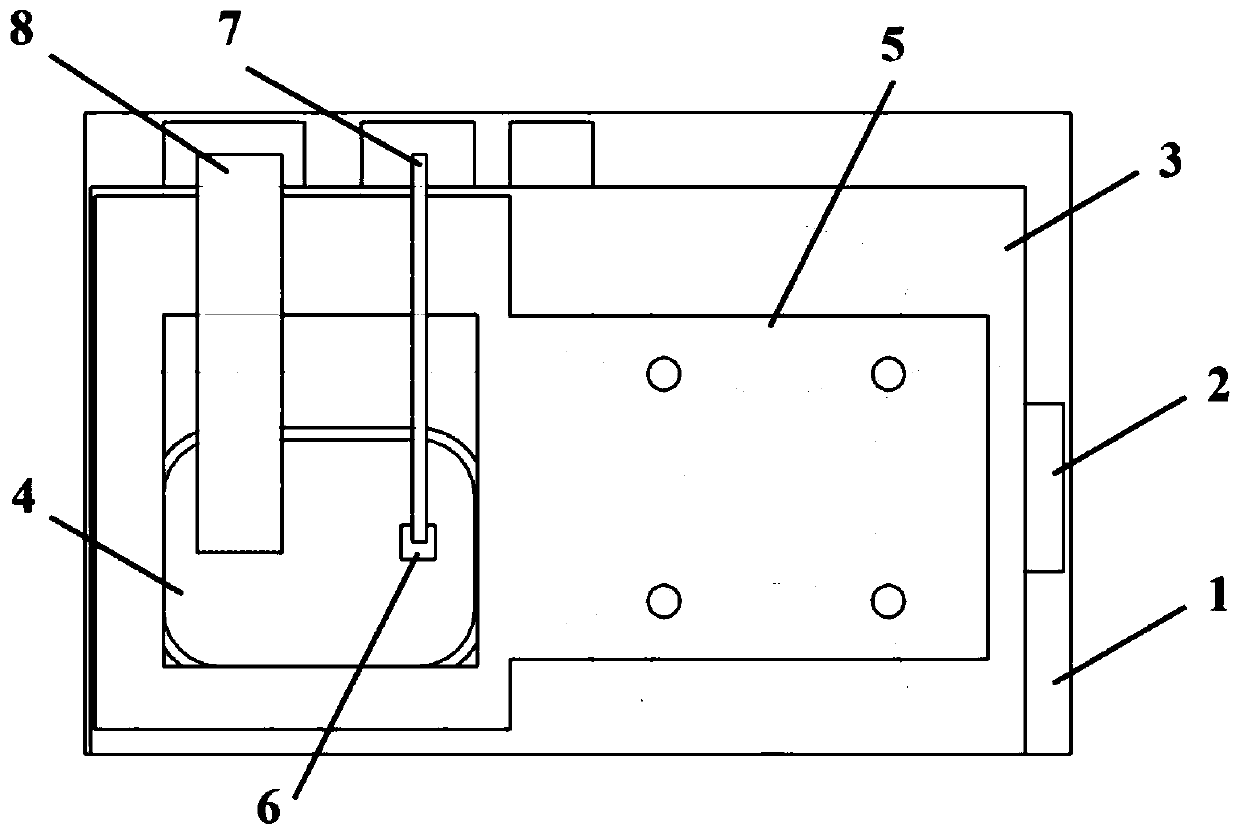

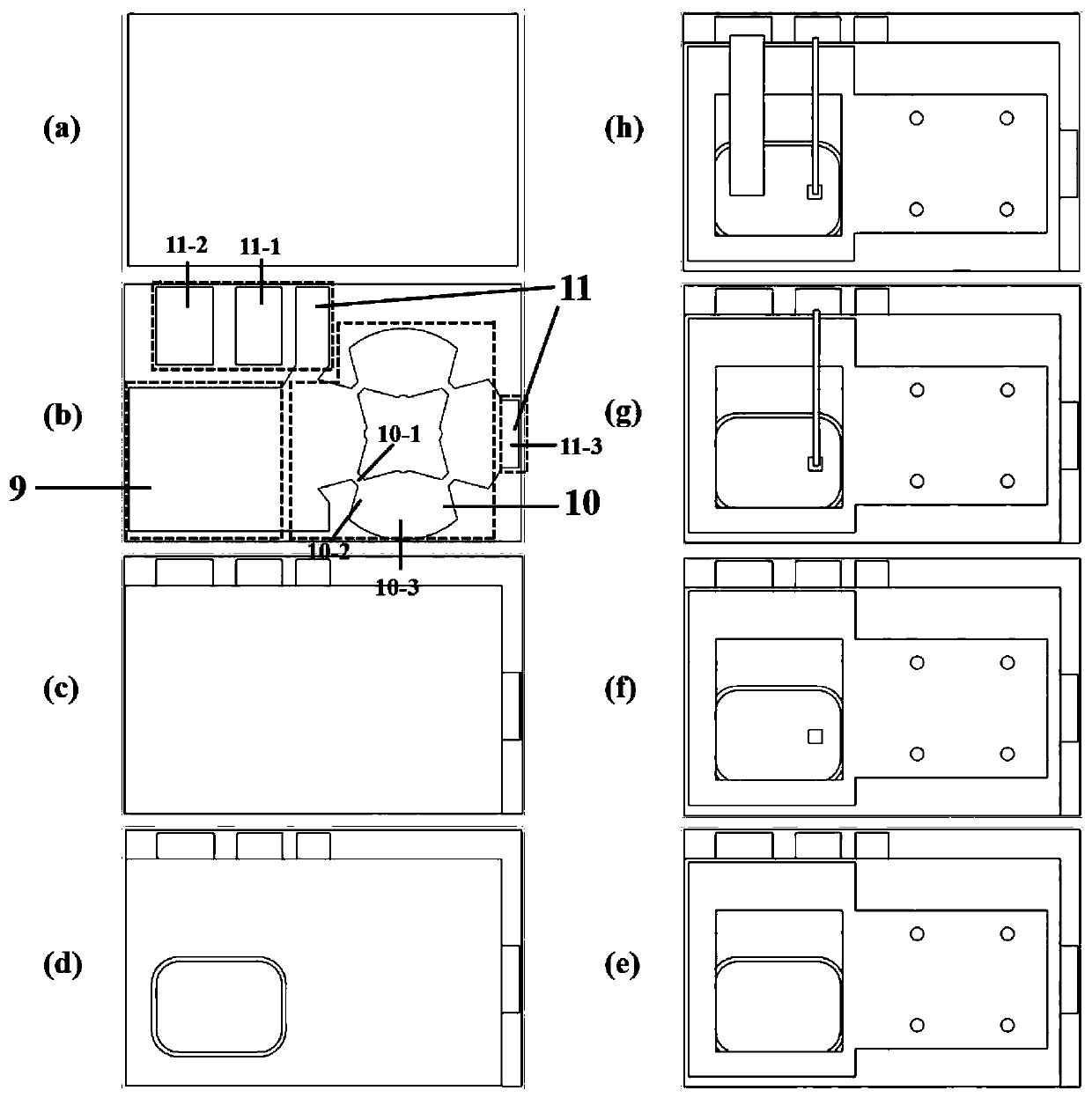

[0053] An exploding foil overpressure chip with integrated one-shot switch, such as figure 1 , figure 2 shown. The chip includes a ceramic substrate 1, a metal TiW / Cu layer 2, a ParyleneC layer 3, an upper electrode TiW / Cu / Au4, a Su8 accelerating chamber 5, a high-voltage diode 6, a welding wire 7 and a conduction band 8; the ceramic substrate 1 A metal TiW / Cu layer 2 is arranged on the top; the metal TiW / Cu layer 2 is divided into a lower electrode area 9, an explosion foil array area 10 and a pad area 11, wherein the lower electrode area 9 has a rectangular structure, and the explosion foil array area 10 is Similar to a ring-shaped structure, it is divided into explosive foil 10-1, transition zone 10-2 and connection zone 10-3, wherein the explosive foil 10-1 is the narrowest part of the explosive foil array zone 10, there are four, connected The method is that two explosive foils 10-1 are connected in series first, and then connected in parallel; the transition zone 10-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com