Fire-resistant drop optical cable and manufacturing method thereof

A technology for introducing optical cables and fire resistance, which is applied in the field of optical cable manufacturing, can solve the problems that the flame retardant sheath is difficult to achieve fire prevention, the communication interruption of optical cable lines, and the damage to the integrity of optical cable lines, and achieves excellent bending resistance, excellent high temperature resistance and combustion resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

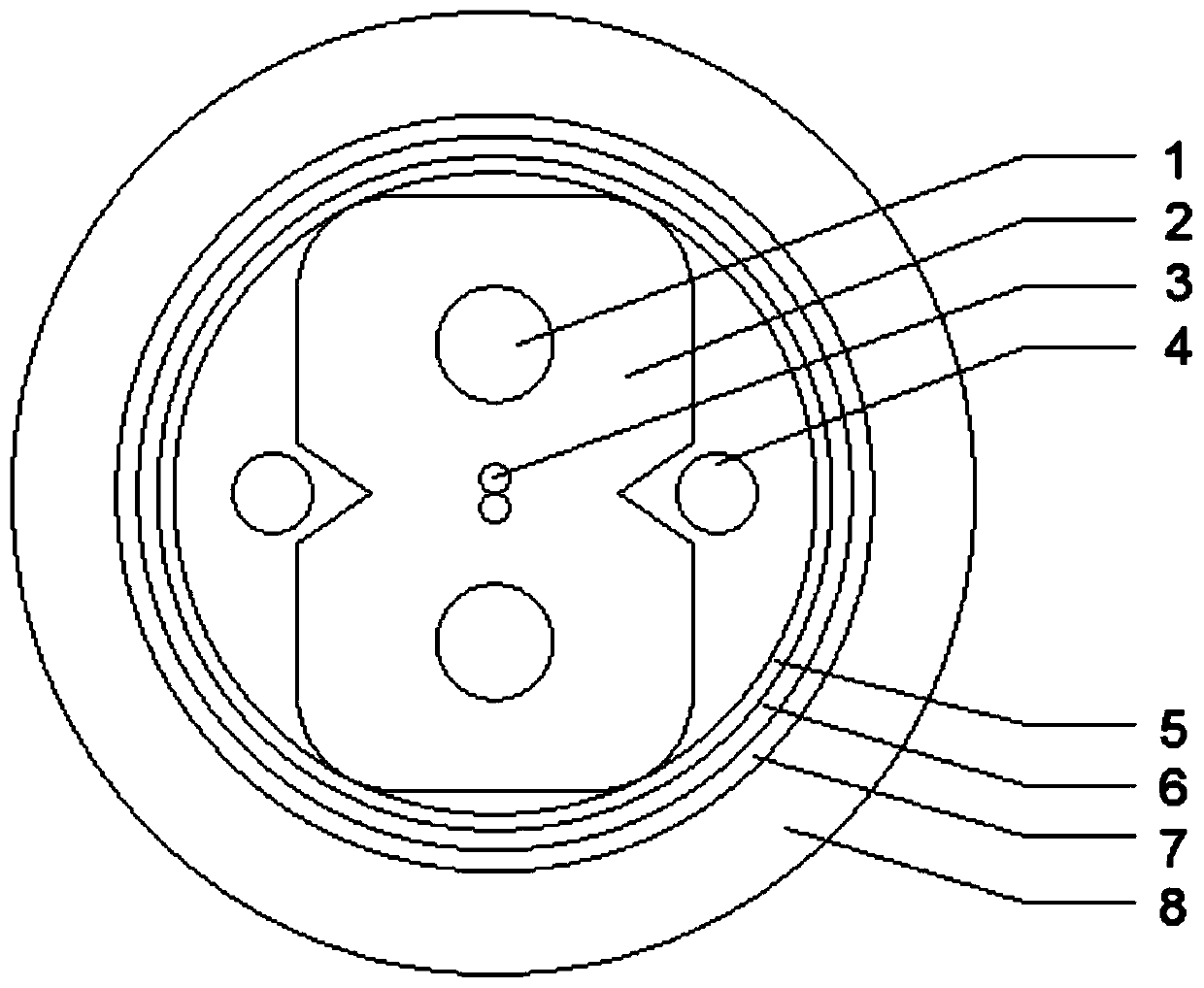

[0024] refer to figure 1 , the present invention includes an optical fiber 3 and an inner sheath 2 that wraps the butterfly-shaped section of the optical fiber 3, and its size is 3.0mm*2.0mm. The inner sheath 2 is embedded with two KFRP strength members 1 that are symmetrical to the center of the optical fiber 3, Its diameter is 0.58 mm, and two phosphating steel wires of the metal auxiliary reinforcement 4 are respectively placed in the two open slots on both sides of the inner sheath 2, and the diameter is 0.6 mm. Then, the water-blocking layer 5 is longitudinally wrapped from the inside to the outside, and its longitudinal wrapping diameter is 4.0mm; the water-blocking layer 5 is wrapped longitudinally with an isolation layer 6, and its longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com