Lithium ion battery membrane diaphragm and preparation method thereof

A lithium-ion battery and separator technology, applied in the field of lithium-ion battery membrane separator and its preparation, can solve the problems of unsatisfactory pore size distribution and the need to improve the consistency of the separator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

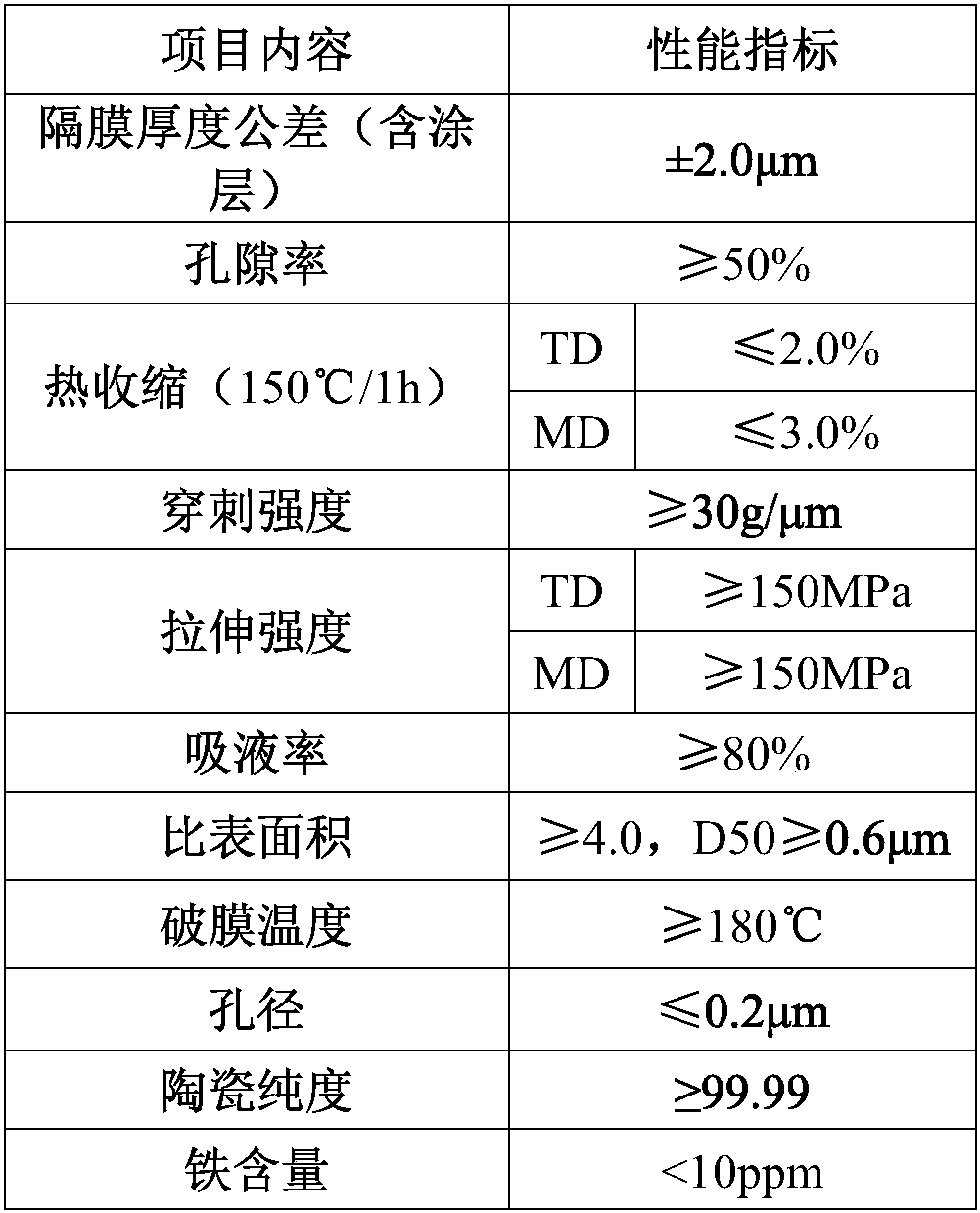

[0024] A lithium-ion battery membrane diaphragm, a ceramic layer composite diaphragm with a three-dimensional network structure, its composition includes the following raw materials by weight: SiO 2 0.5 parts, Al 2 o 3 1 part, TiO 2 2 parts, PVDF powder 0.01 part and ceramic powder 1 part.

[0025] The liquid absorption rate of the lithium-ion battery membrane diaphragm is ≥ 80%.

[0026] The specific surface area of the lithium-ion battery membrane diaphragm is ≥ 4.0, and D50 ≥ 0.6 μm.

[0027] The membrane rupture temperature of the lithium-ion battery membrane separator is ≥180°C.

[0028] The pore diameter of the lithium-ion battery membrane separator is ≤0.2 μm.

[0029] The purity of the lithium-ion battery diaphragm ceramics is more than or equal to 99.99.

[0030] The iron content of the lithium-ion battery membrane separator is less than 10ppm.

[0031] A kind of preparation method of lithium ion battery diaphragm of the present invention comprises the fol...

Embodiment 2

[0034] A lithium-ion battery membrane diaphragm, a ceramic layer composite diaphragm with a three-dimensional network structure, its composition includes the following raw materials by weight: SiO 2 0.7 parts, Al 2 o 3 2 parts, TiO 2 3 parts, 0.02 parts of PVDF powder and 2 parts of ceramic powder.

[0035] The liquid absorption rate of the lithium-ion battery membrane diaphragm is ≥ 80%.

[0036] The specific surface area of the lithium-ion battery membrane diaphragm is ≥ 4.0, and D50 ≥ 0.6 μm.

[0037] The membrane rupture temperature of the lithium-ion battery membrane separator is ≥180°C.

[0038] The pore diameter of the lithium-ion battery membrane separator is ≤0.2 μm.

[0039] The purity of the lithium-ion battery diaphragm ceramics is more than or equal to 99.99.

[0040] The iron content of the lithium-ion battery membrane separator is less than 10ppm.

[0041] A kind of preparation method of lithium ion battery diaphragm of the present invention comprise...

Embodiment 3

[0044] A lithium-ion battery membrane diaphragm, a ceramic layer composite diaphragm with a three-dimensional network structure, its composition includes the following raw materials by weight: SiO 2 1 copy, Al 2 o 3 3 parts, TiO 2 4 parts, 0.03 parts of PVDF powder and 3 parts of ceramic powder.

[0045] The liquid absorption rate of the lithium-ion battery membrane diaphragm is ≥ 80%.

[0046] The specific surface area of the lithium-ion battery membrane diaphragm is ≥ 4.0, and D50 ≥ 0.6 μm.

[0047] The membrane rupture temperature of the lithium-ion battery membrane separator is ≥180°C.

[0048] The pore diameter of the lithium-ion battery membrane separator is ≤0.2 μm.

[0049] The purity of the lithium-ion battery diaphragm ceramics is more than or equal to 99.99.

[0050] The iron content of the lithium-ion battery membrane separator is less than 10ppm.

[0051] A kind of preparation method of lithium ion battery diaphragm of the present invention comprises t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| membrane rupture temperature | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com