Seamless sculpture elastic band production device

A production equipment and elastic band technology, applied in the direction of pretreatment surface, coating, surface coating liquid device, etc., can solve the problems of limited webbing elasticity, wrinkle and fold, loss of resilience, etc., to ensure stickiness and durability , Improve production efficiency and ensure firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

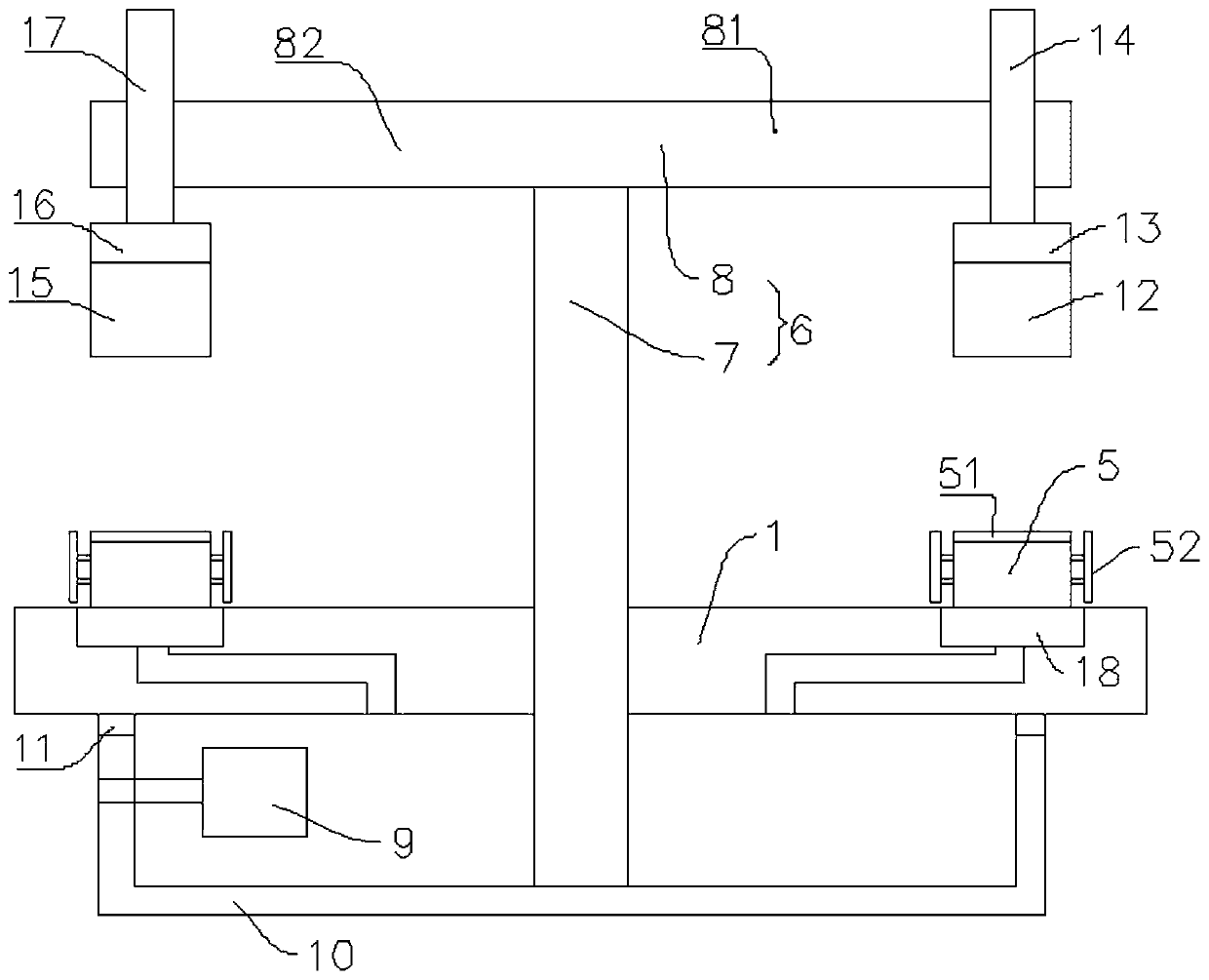

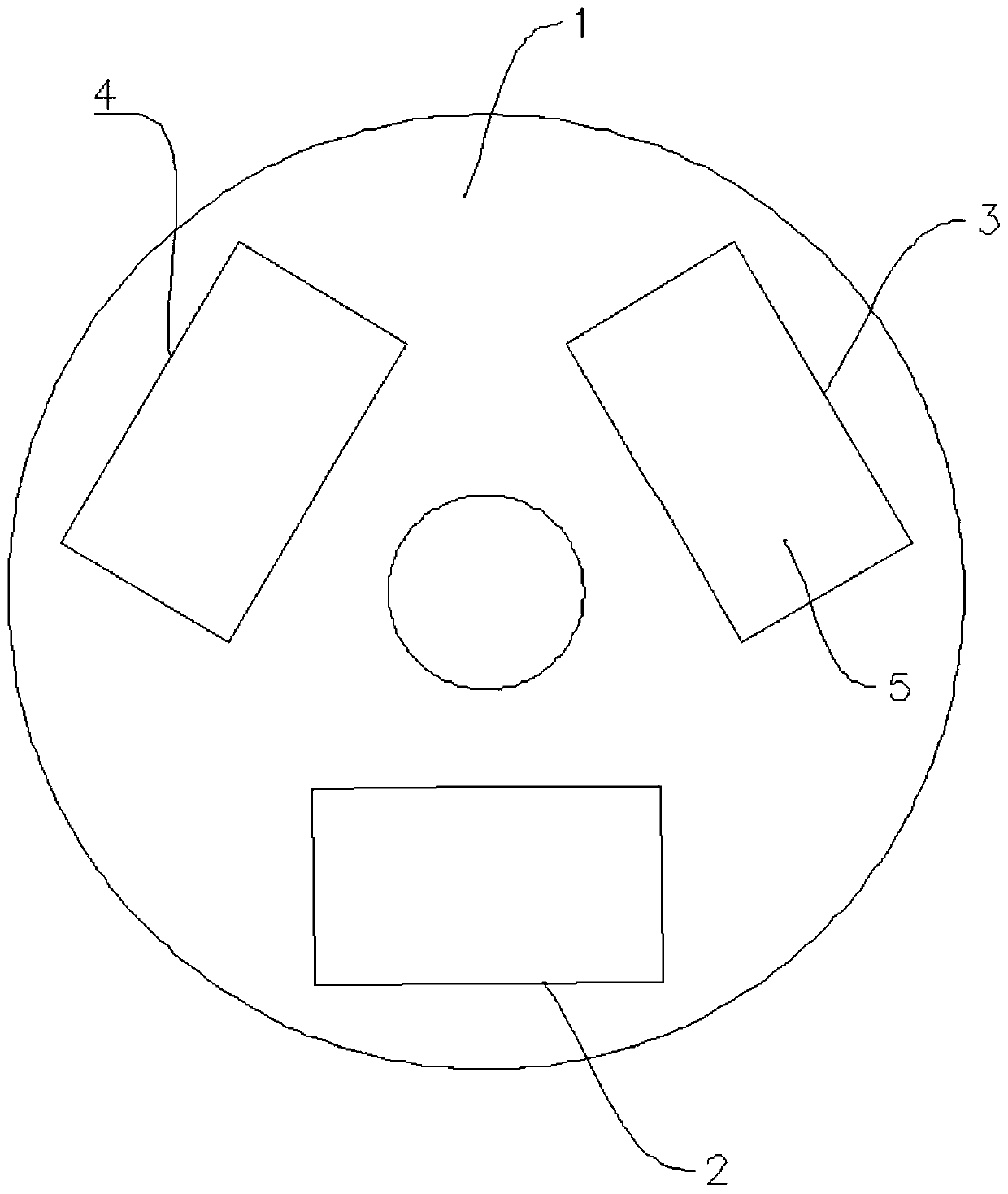

[0033] A seamless sculpture elastic band production equipment, such as figure 1 with figure 2 As shown, the equipment includes a rotary turntable 1, and a material preparation area 2, a pre-setting area 3 and a shaping area 4 are sequentially arranged on the circumference of the rotary turntable 1. A lower mold 5 is all arranged in the areas of the material preparation area 2, the pre-setting area 3 and the shaping area 4, the lower molds 5 are distributed in a circle and the angle between two adjacent lower molds 5 is 120 degrees. Lower mold 5 is for the placement of raw materials in the process of processing.

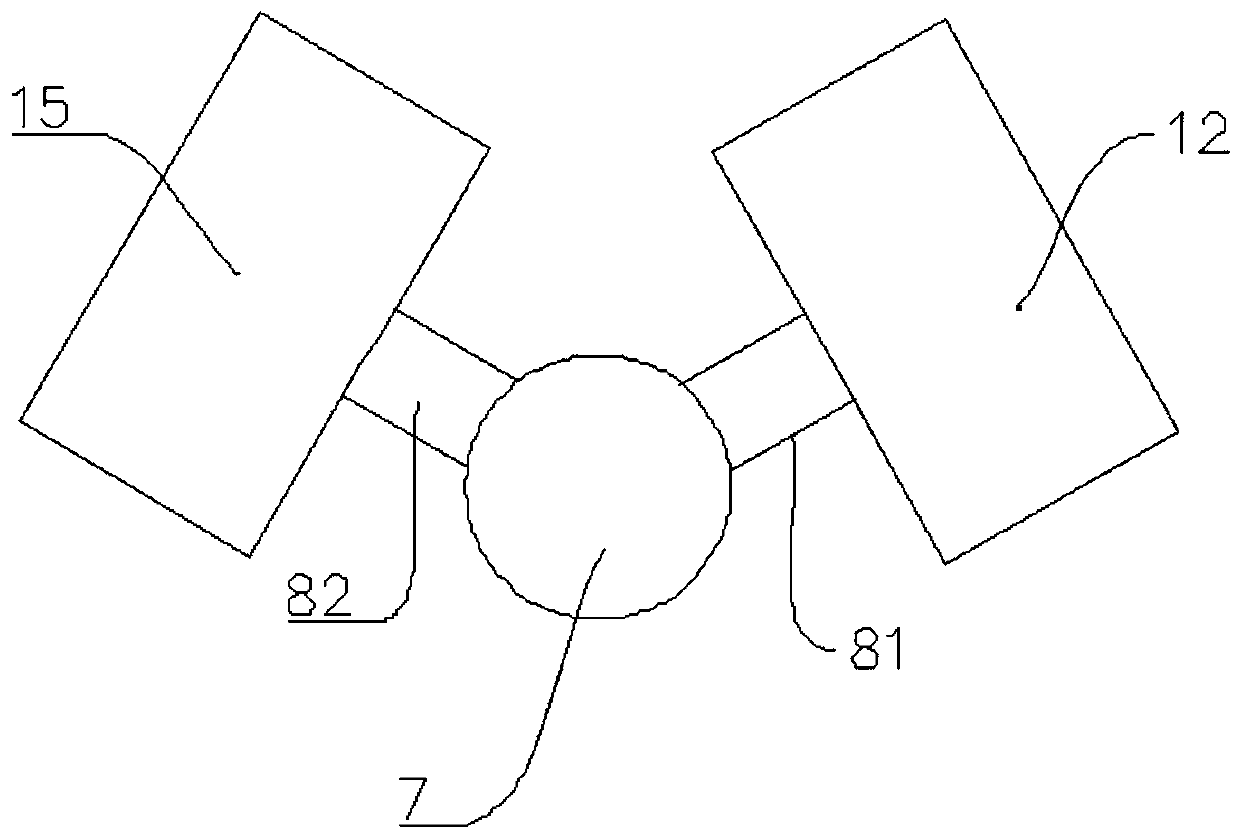

[0034] Such as figure 1 As shown, a mounting bracket 6 is also included, and the mounting bracket 6 includes a support rod 7 arranged vertically at the center of the rotary turntable 1 and a side arm 8 that is horizontally connected to the support rod 7, and the support rod 7 passes through Set in the hole in the center of the turntable, the support rod 7 and the ...

Embodiment 2

[0041] A kind of production technology of textile necking, such as Figure 5 As shown, the materials used in the process are as follows:

[0042] (1) Prepare the base fabric, webbing and hot-melt adhesive film.

[0043] Base fabric, the base fabric is made of chemical fiber, which should be elastic, and silicon soft treatment is strictly prohibited.

[0044] Hot-melt adhesive film, select the hot-melt adhesive film with low melting point and good viscosity. The types of hot-melt adhesive film that can be used in this embodiment are as follows: Bemis 3415-6MIL, DZ 3258-6MIL, DZ 6585-6MIL, DZ 6625- 6MIL.

[0045] For the webbing, choose a webbing with high elasticity and a thinner body to improve the comfort and resilience after bonding, and silicon soft disposal is strictly prohibited.

[0046] According to the shape, the ribbon can be divided into a straight mouth and a double mouth. The straight mouth is a strip shape, and the double mouth is the side opening of the strip bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com