Winnowing machine for grain processing

A winnowing machine and grain technology, applied in the direction of separating solids from solids with airflow, solid separation, chemical instruments and methods, etc., can solve problems such as inconvenient use, and achieve convenient use, convenient grain collection, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

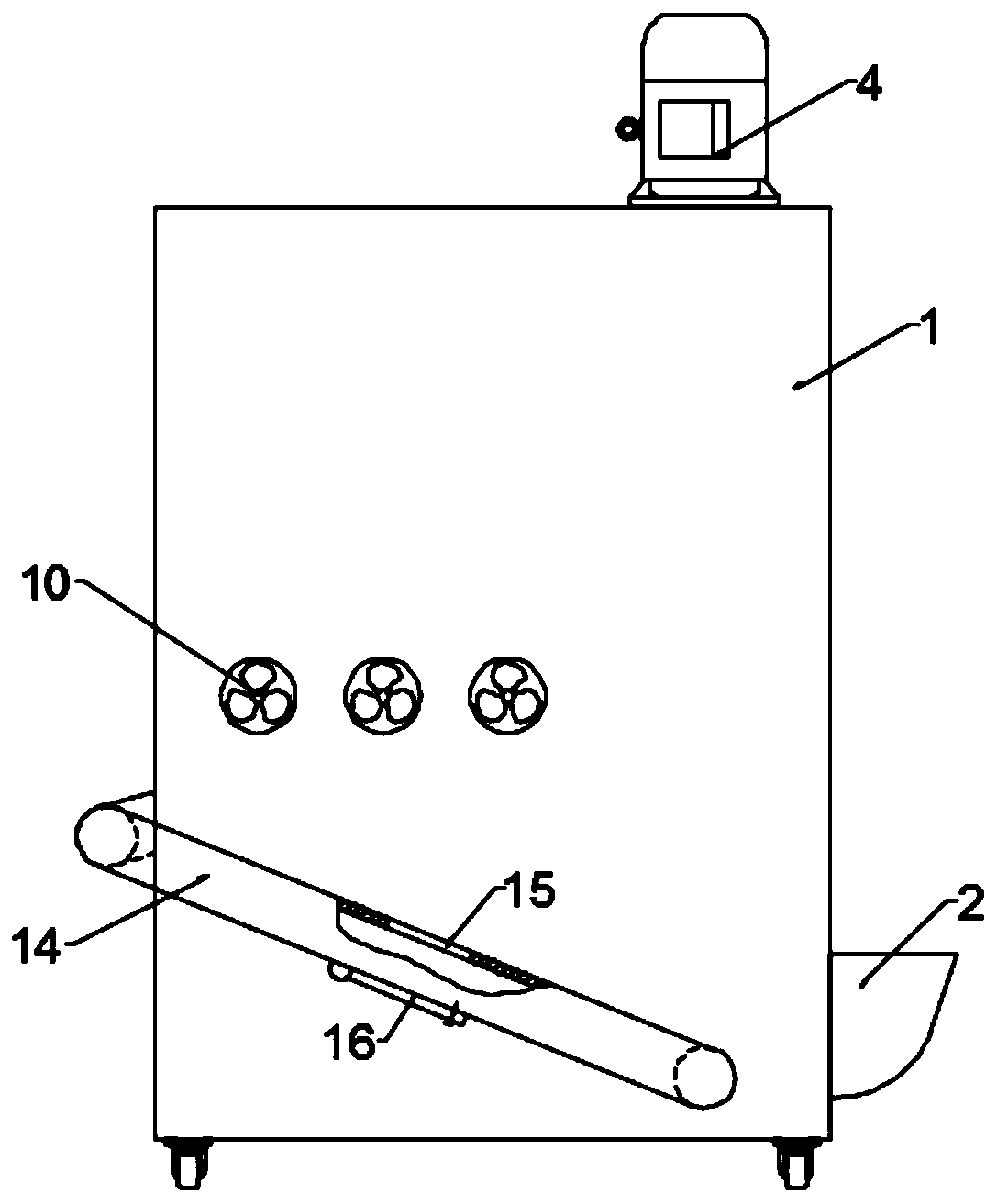

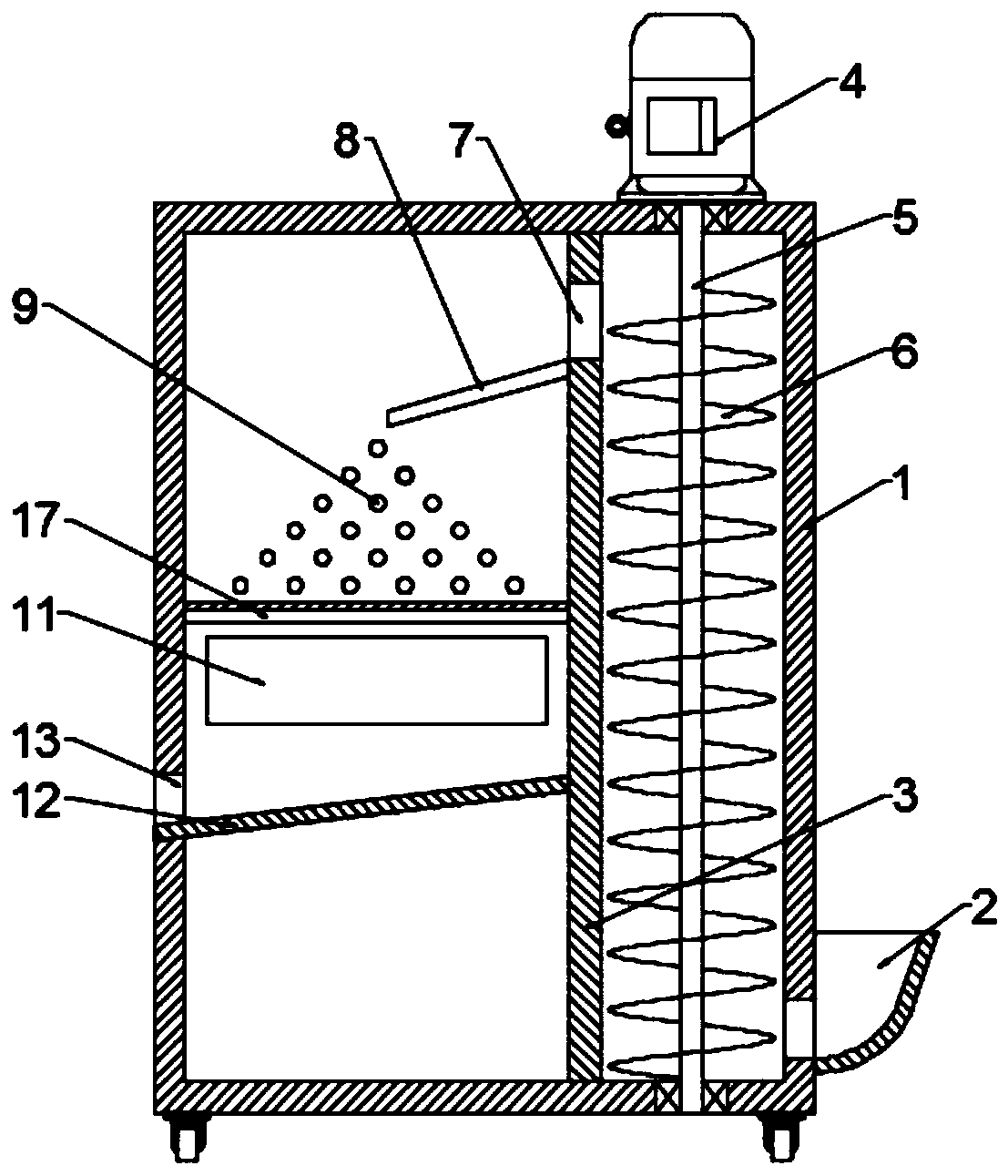

[0022] Example 1: Please refer to Figure 1-3 , a wind separator for grain processing, comprising a processing box 1, a feed hopper 2 is fixedly connected to the bottom right of the processing box 1, a longitudinal partition 3 is fixedly connected to the inner side of the processing box 1, and the right side of the top of the processing box 1 is fixedly connected to There is a motor 4, the output end of the motor 4 is fixedly connected with a longitudinal rotating shaft 5, the longitudinal rotating shaft 5 runs through the processing box 1 and is rotationally connected with the processing box 1;

[0023] Turn on motor 4 during use, motor 4 rotates and waits for the vertical shaft 5 to rotate, and the rotation of vertical shaft 5 can drive the screw auger 6 to rotate, and the space on the right side of the longitudinal dividing plate 3 is cylindrical, which is convenient to drive the grain to move upwards;

[0024] The outer side of the longitudinal rotating shaft 5 is fixedly ...

Embodiment 2

[0035] Embodiment 2: This embodiment is a further improvement of the previous embodiment: Universal wheels are installed at the bottom of the device to facilitate movement. In addition, the maximum opening angle of the discharge baffle 16 is limited, and it can be in an inclined state after opening, which can be directly Conduct feed.

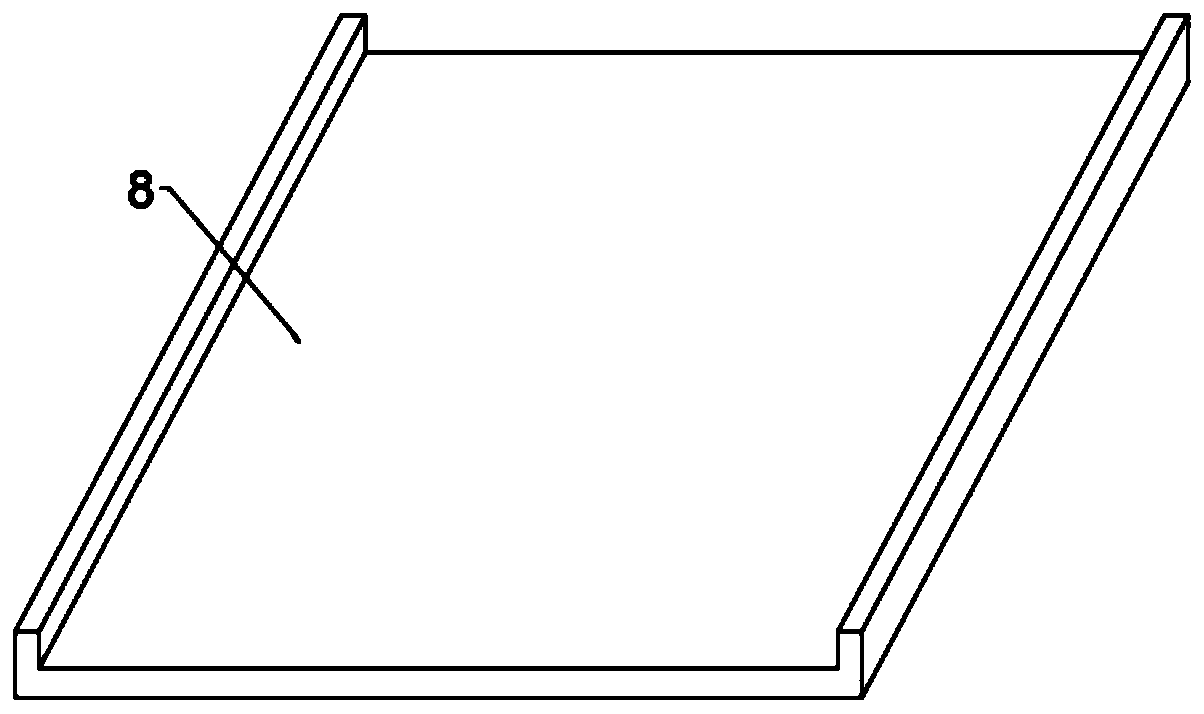

[0036] The working principle of the present invention is: turn on the motor 4 when in use, the motor 4 rotates and the longitudinal shaft 5 rotates, and the rotation of the longitudinal shaft 5 can drive the screw auger 6 to rotate, and the space on the right side of the longitudinal partition 3 is cylindrical, which is convenient to drive the grain upward. After that, the grain enters the material distribution rod 9 through the screening material opening 7 and the first guide plate 8, and is dispersed into the bottom under the action of the material distribution rod 9, and the fan 10 is turned on, and the fan 10 can discharge light impurities t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com