Equipment for performing on-line 360-degree up, down, left and right omnidirectional grinding and polishing on pipe making machine

An all-round technology, applied in grinding/polishing equipment, grinding/polishing safety device, metal processing equipment, etc., can solve the problems of increasing difficulty in polishing, inability to polish tube shape, obvious grinding marks, etc. The effect of small exposed area, reduced mold pressing force, and reduced maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

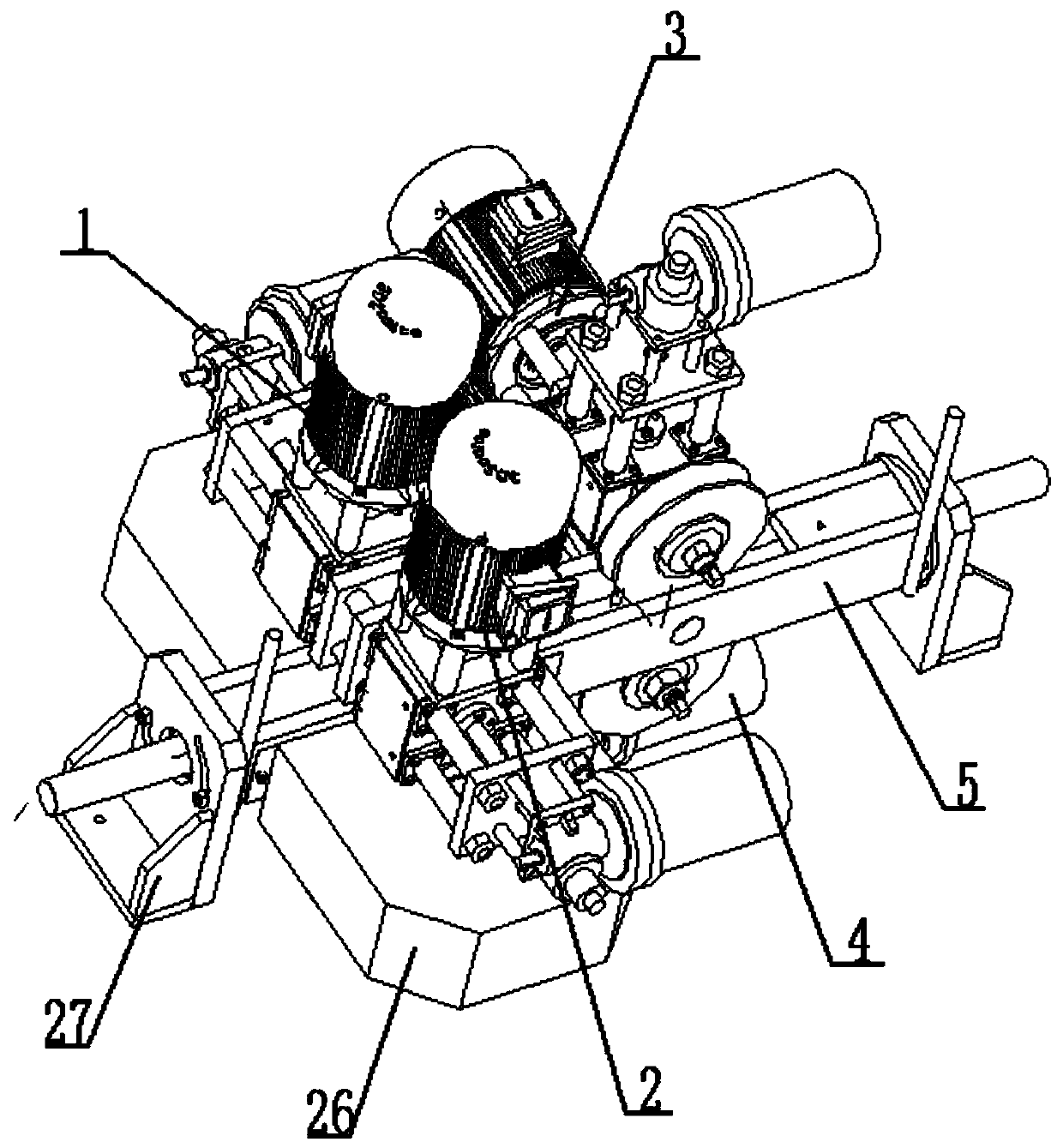

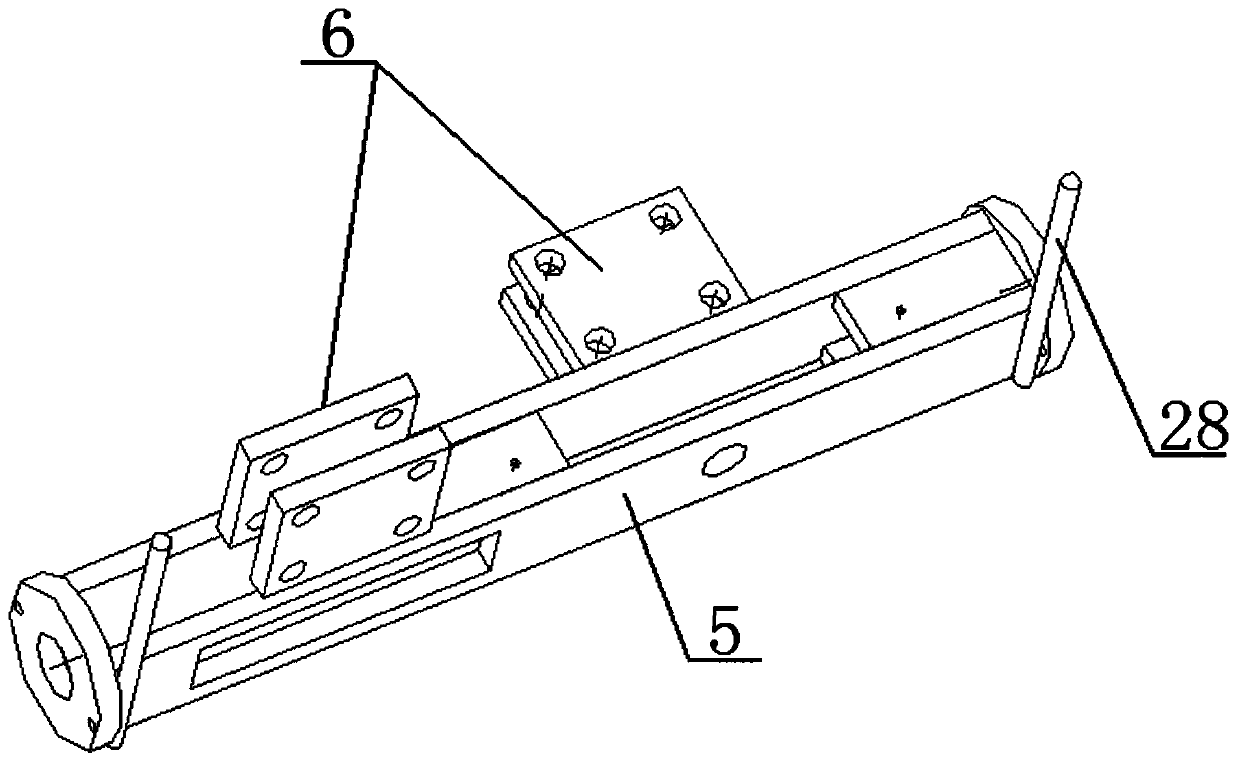

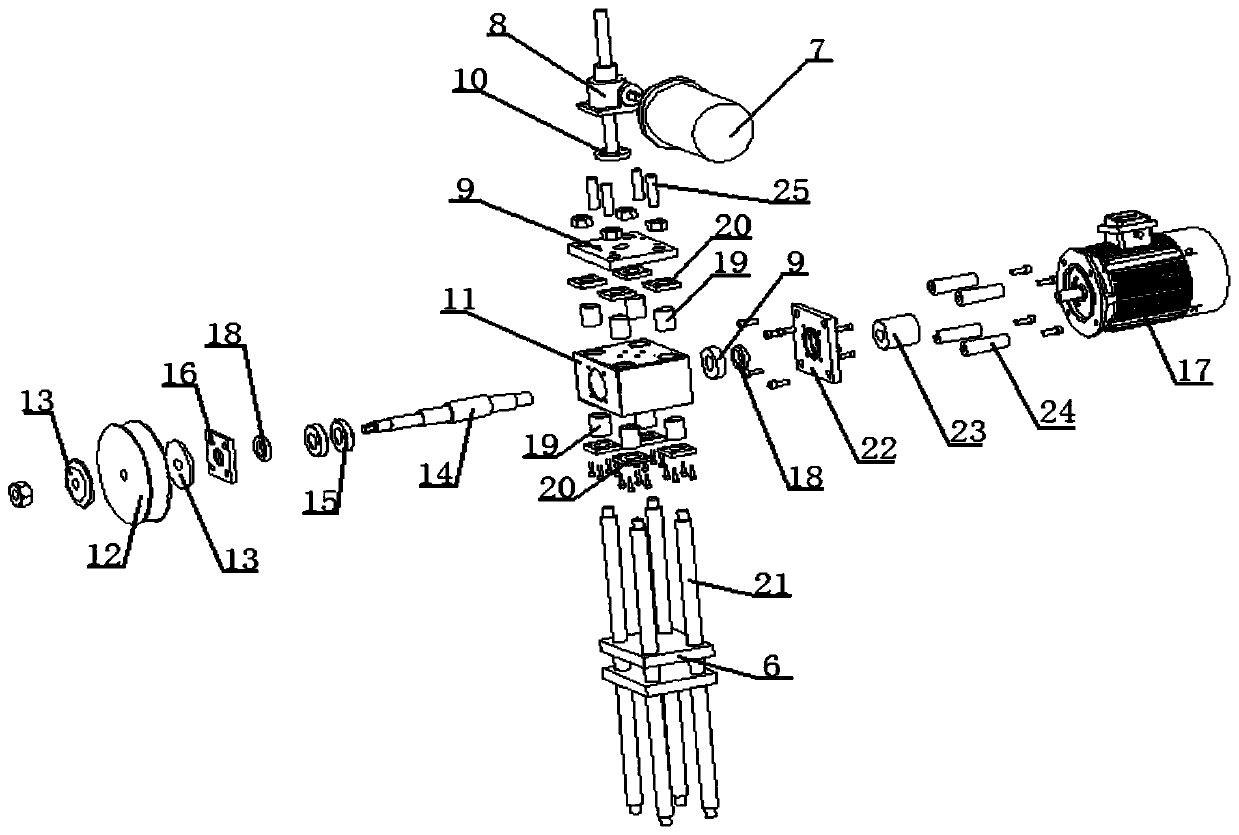

[0026] like Figure 1-7As shown in the figure, a kind of grinding and polishing equipment with 360 degrees up, down, left, and right on the line of the pipe making machine includes the installation frame 5 which plays the role of the installation base and the right grinding head 1, the left grinding head 2 and the upper grinding head 3 which play the role of grinding. , The lower grinding head 4, the mounting frame 5 is a rectangular frame welded by steel plates, the two ends of the rectangular frame are welded and fixed with discs, the mounting frame 5 is welded and fixed with four grinding head mounting plates 6, and the four grinding head mounting plates 6 are parallel to each other Welding, the angle between the two groups is 90 degrees, two h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com