Bottle cap positioning method for laser code printing of bottle caps

A positioning method and bottle cap technology, applied in laser welding equipment, copy/marking method, temperature recording method, etc., can solve problems such as easy deviation, bottle cap screening, poor coding quality, etc., to achieve convenient coding, Improve work efficiency and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

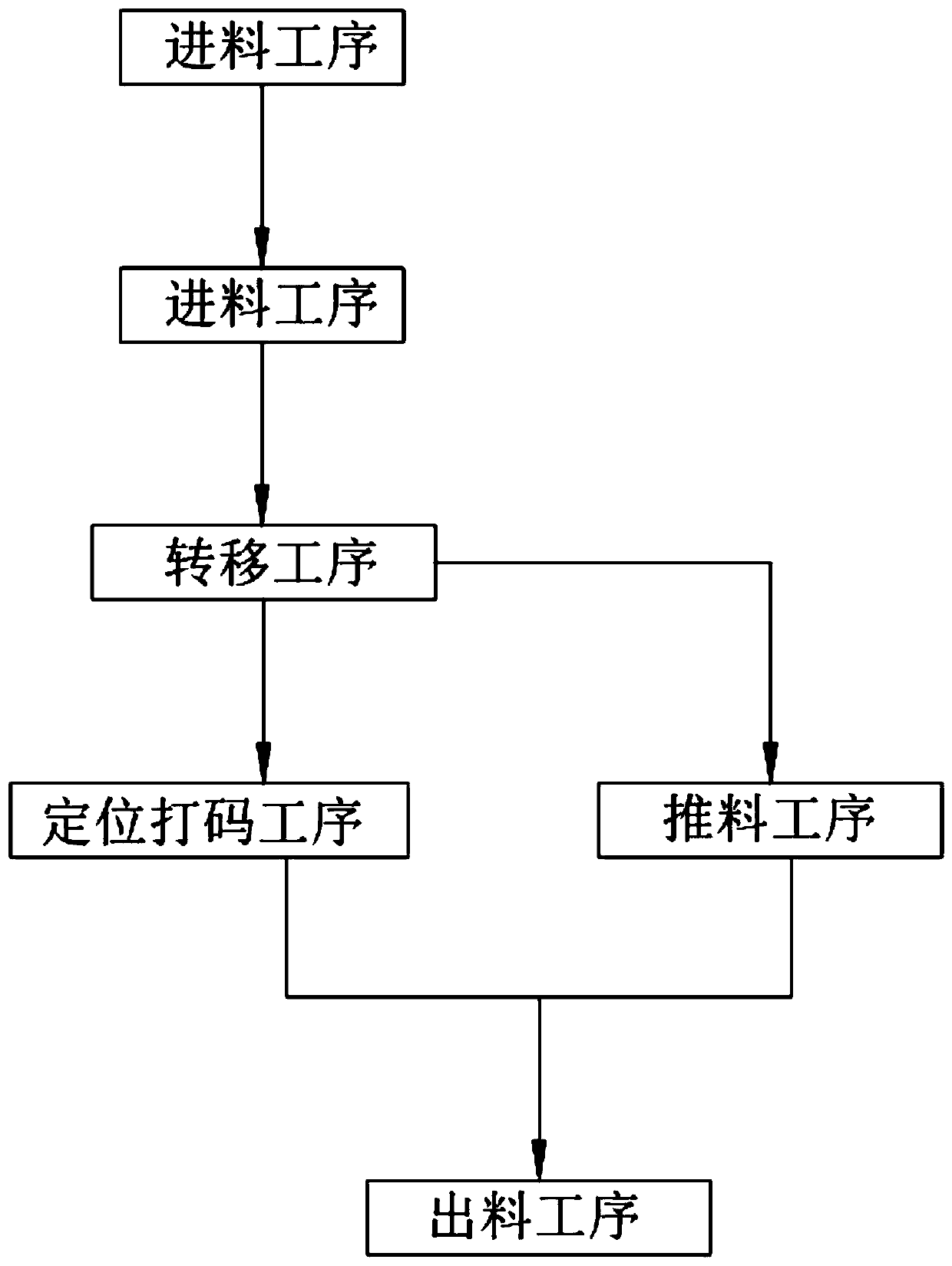

[0044] Such as figure 1 , figure 2 As shown, a bottle cap positioning method for laser marking, including:

[0045] Step 1, the feeding process, the bottle caps 100 from the belt feeding device 12 enter the feeding pipe 11 in sequence;

[0046] Step 2, the screening process, the material receiving column 34 of the feeding assembly 3 is located on the feeding station, the bottle cap with the cap facing down falls on the material receiving column 34 arranged under the guide tube 11, and the rest remain in the guide tube 11. Inside the material pipe 11;

[0047] Step 3, the transfer process, when the bottle cap falls on the material guide tube 11, the material receiving column 34 rotates in a circle, the material receiving column 34 rotates from the loading station to the coding station, and the bottle cap in the material guide tube 11 falls on the In the first receiving basin 13;

[0048] Step 4, positioning coding process, the rotating wheel 38 rotates to the bottom along ...

Embodiment 2

[0062] Such as figure 2 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

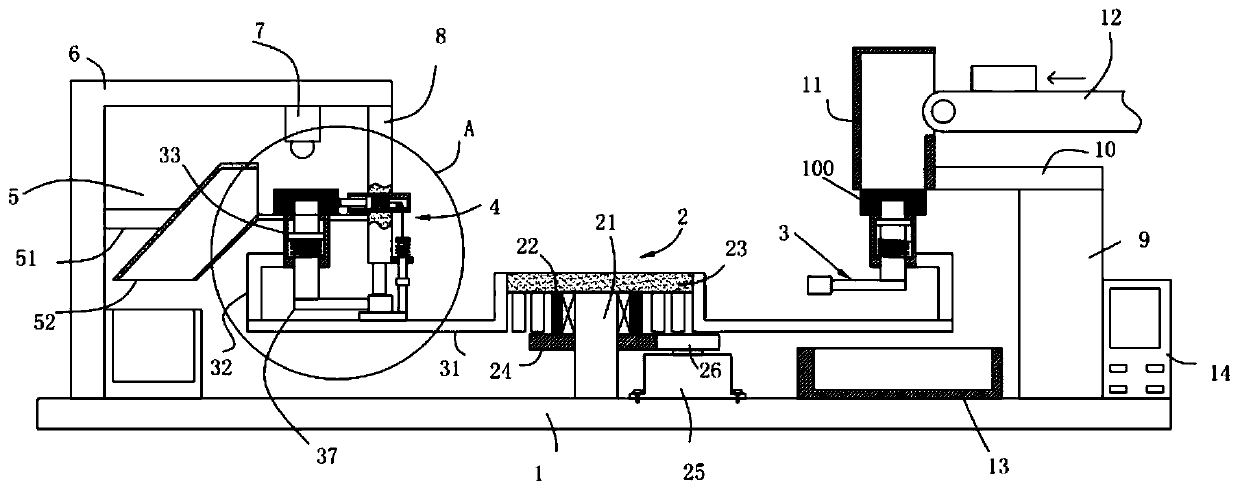

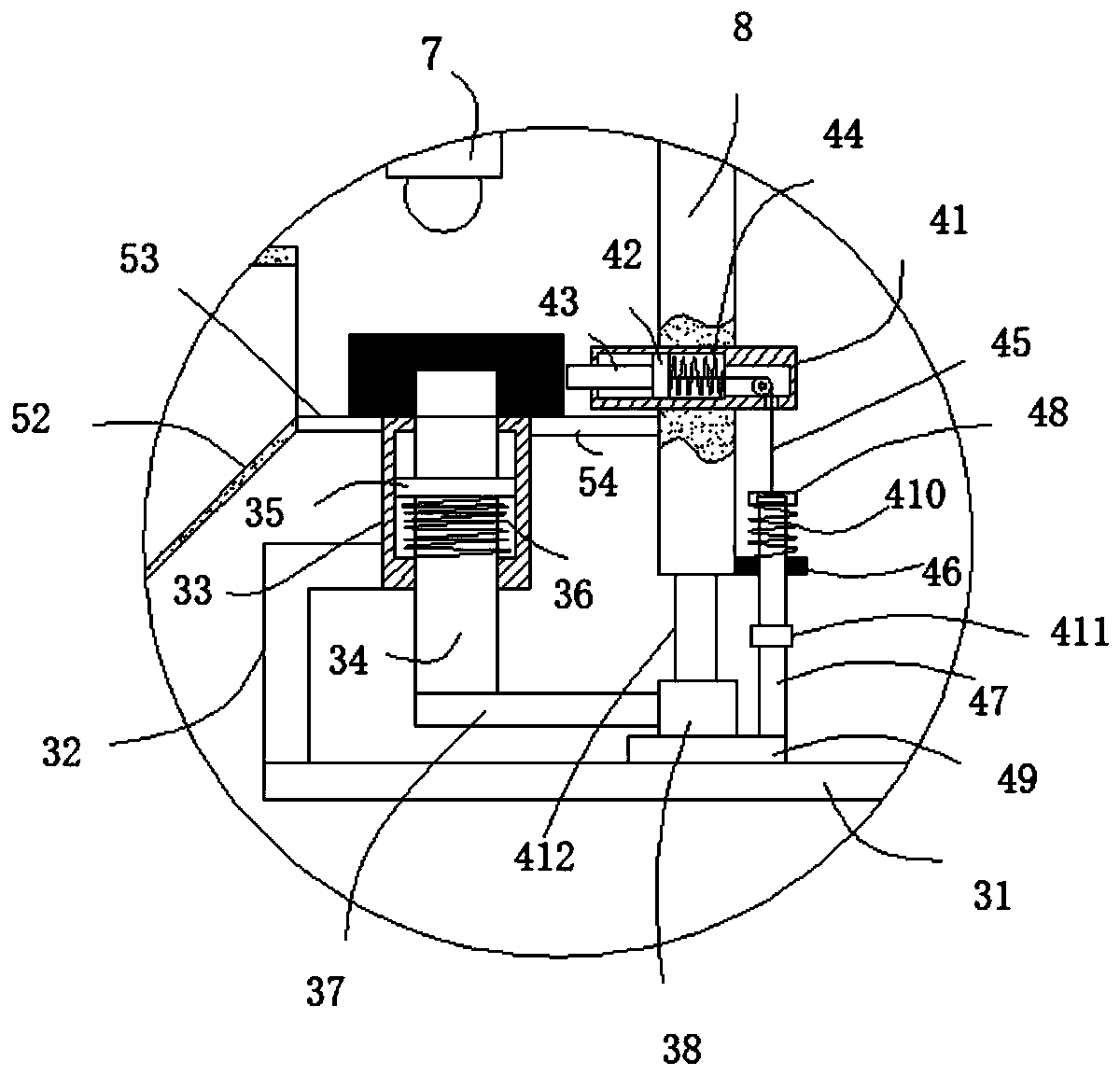

[0063] A bottle cap positioning device for packaging bottle cap coding, comprising a base 1 and a controller 14 fixed on the base 1, an L-shaped fixing plate 6 is fixed on the base 1, and a vertical The laser marking terminal 7 and the mounting plate 8 are equipped with a stripping assembly 4 on the mounting plate 8, a receiving assembly 5 matching the stripping assembly 4 is installed on the L-shaped fixed plate 6, and a driving assembly 2 is installed on the base 1. The driving assembly 2 is fixed with feeding assemblies 3 arranged in a circular array, the leftmost feeding assembly 3 is located below the laser mar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com