Harness separator and battery pack

A technology of separators and battery packs, applied in electrical components, vehicle components, electric power devices, etc., can solve the problems of low connection strength, insulation and short circuit, and scattered wiring harness layout of battery packs, so as to avoid insulation and short circuit, reduce Friction, collocation and flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

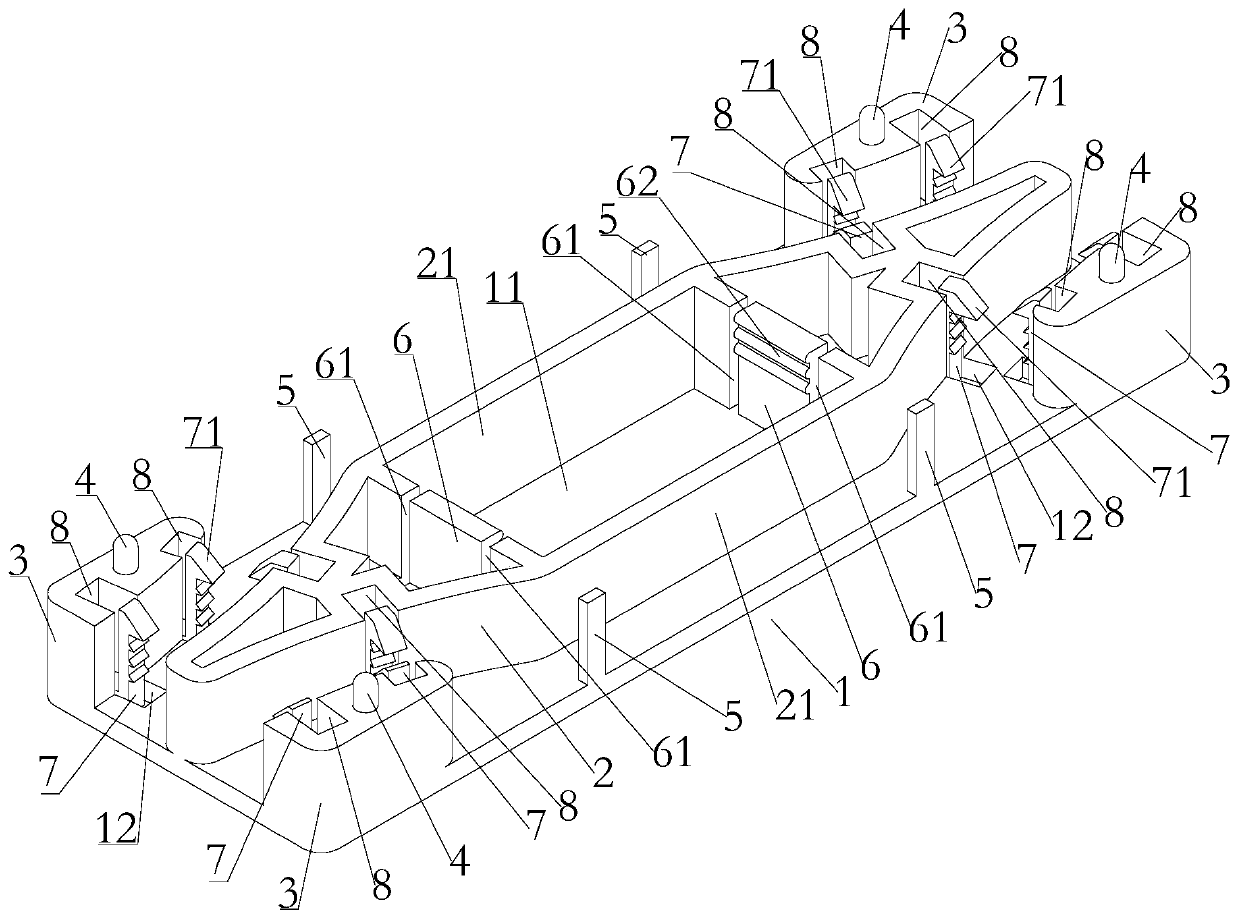

[0033] Such as figure 1 and figure 2 As shown, a wire harness isolator in this embodiment includes a spacer body 1 with a planar structure, and a through hole 11 is provided in the middle of the spacer body 1 for being sleeved on the internal structural member 9 of the battery pack. The middle part of the upper surface of the spacer body 1 is provided with a coaming plate 2, and the edge is provided with a limiting member 3. Two wire harness passages are defined, and the two wire harness passages are respectively located on both sides of the through hole 11 . Among them, the spacer body 1 of this embodiment is integrally formed and supported by an injection molding process, and the injection molded part has the properties of aging resistance, acid and alkali resistance, high temperature resistance, and salt spray resistance, which increases the safety of use.

[0034] In the wire harness spacer of this embodiment, by setting the body of the spacer, and setting a through hol...

Embodiment 2

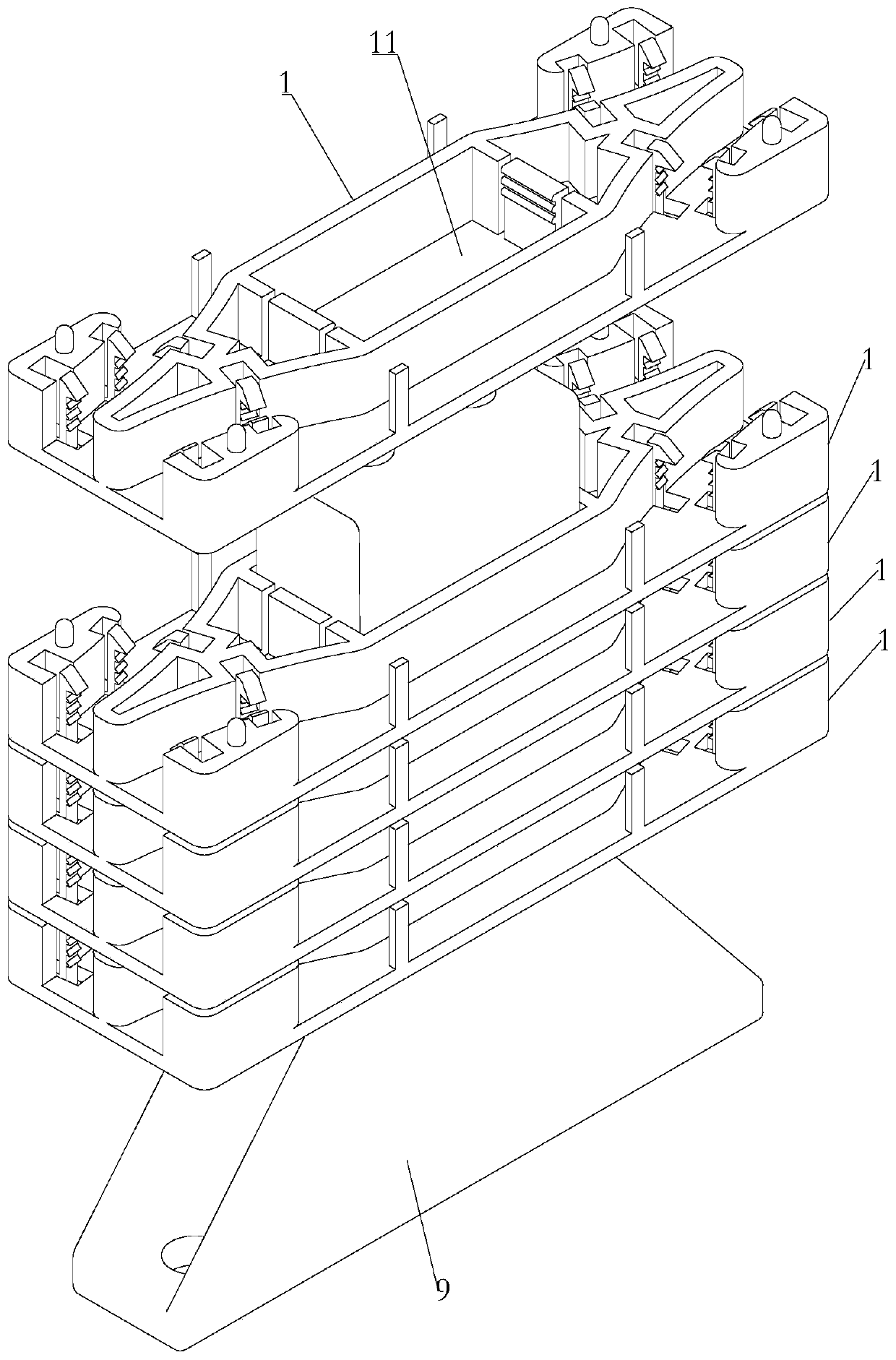

[0048] A battery pack in this embodiment includes a battery pack body, a structural member 9 and several wire harness spacers, the structural member 9 is installed in the battery pack body, and several spacer bodies 1 pass through the middle The through holes 11 are sleeved on the structural member 9 and arranged superimposedly.

[0049] Wherein, a preferred solution of this embodiment is that a two-layer module tray is arranged inside the battery pack body, the bottom of the structural member 9 is fixedly connected to the inner side of the battery pack body, and the top is fixedly connected to the two-layer module tray. The two sides of the structural member 9 are respectively provided with battery modules, and the spacer body 1 can be sleeved on the structural member 9, and the wiring harness channel on the spacer body 1 is used to isolate and clamp the wiring harness of each battery module and limit etc.

[0050] In the battery pack of this embodiment, the wiring harness i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com