Method for manufacturing and representing magnesium oxychloride cement (MOC) foam concrete air pore structure model based on magnesium phosphate cement

A technology of magnesium oxychloride cement and foam concrete, which is applied in the direction of manufacturing tools, ceramic products, ceramic molding machines, etc., can solve the problems that the depth of the pore structure is not accurately displayed, and the real situation of the internal pores of the foam concrete cannot be directly reflected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

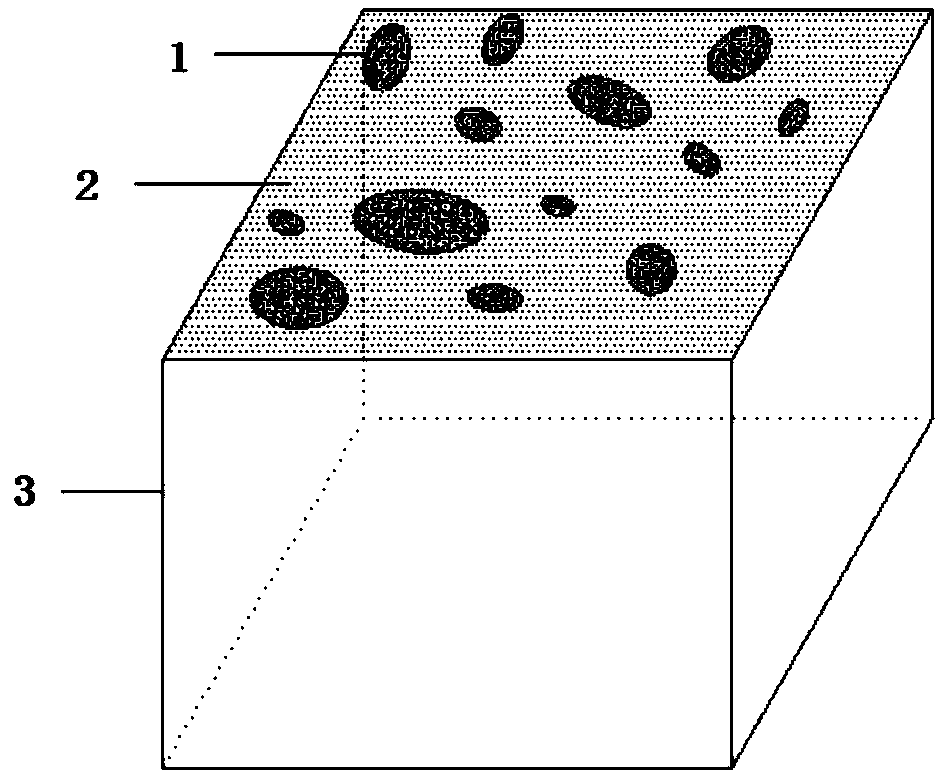

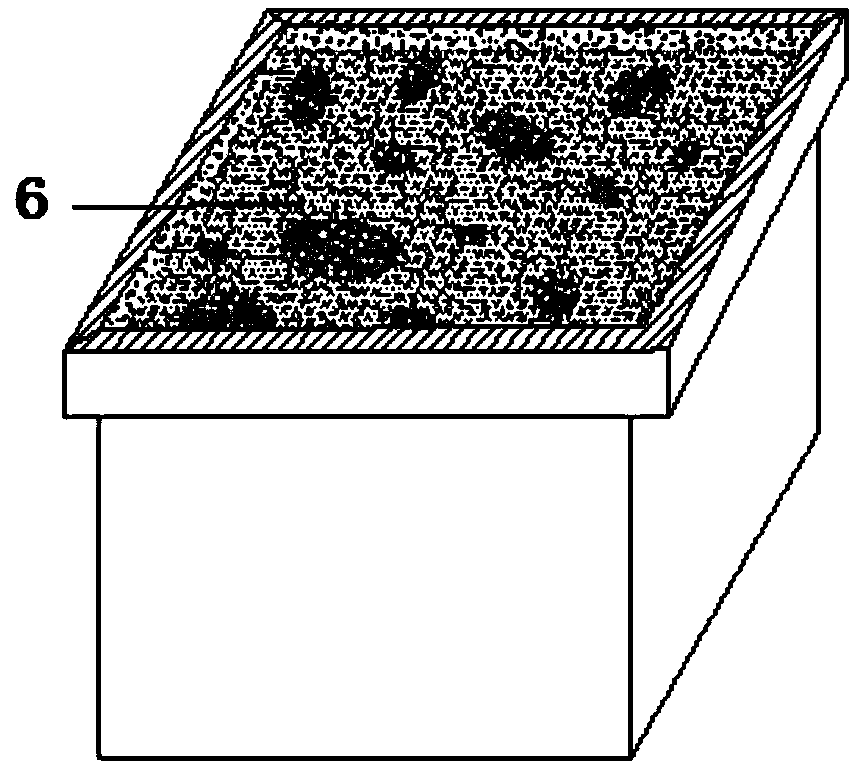

[0041] A method for making a pore structure model of magnesium oxychloride cement foam concrete based on magnesium phosphate cement, comprising the following steps:

[0042] Select a representative magnesium oxychloride cement foam concrete, and cut out the cross-section. The cross-section is kept clean and tidy, and the cut-off sample size is 100mm×100mm×100mm;

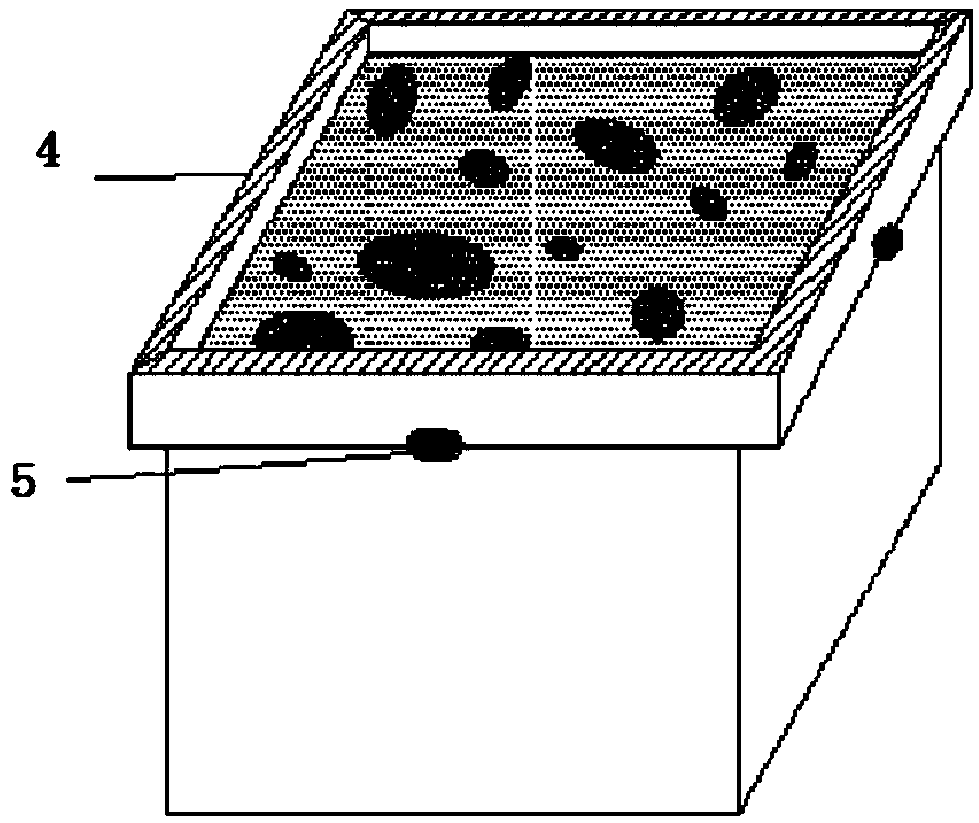

[0043] Magnesium phosphate cement is prepared by putting magnesium oxide, phosphate and modifier into a ball mill for pulverization and mixing to obtain MPC dry powder. , magnesite or dolomite ore calcined inactive magnesium oxide powder, the phosphate is ammonium dihydrogen phosphate, the modifier is borax, magnesium oxide, phosphate and modified The particle size of agent is all less than 75 μ m, and the mass ratio of described magnesia, described phosphate, described modifying agent is 1.5:1:0.1; Add distilled water in described MPC dry powder and mix into magnesium phosphate cement slurry, described MPC The mass...

Embodiment 2

[0058] A method for making a pore structure model of magnesium oxychloride cement foam concrete based on magnesium phosphate cement, comprising the following steps:

[0059] Select a representative magnesium oxychloride cement foam concrete, and cut out the cross-section. The cross-section is kept clean and tidy, and the cut-off sample size is 100mm×100mm×100mm;

[0060] Magnesium phosphate cement is prepared by putting magnesium oxide, phosphate and modifier into a ball mill for pulverization and mixing to obtain MPC dry powder. , magnesite or dolomite ore calcined inactive magnesium oxide powder, the phosphate is ammonium dihydrogen phosphate, the modifier is borax, magnesium oxide, phosphate and modified The particle size of agent is all less than 75 μ m, and the mass ratio of described magnesia, described phosphate, described modifying agent is 2:1:0.08; Add distilled water in described MPC dry powder and mix into magnesium phosphate cement slurry, described MPC The mass ...

Embodiment 3

[0068] A method for making a pore structure model of magnesium oxychloride cement foam concrete based on magnesium phosphate cement, comprising the following steps:

[0069] Select a representative magnesium oxychloride cement foam concrete, and cut out the cross-section. The cross-section is kept clean and tidy, and the cut-off sample size is 100mm×100mm×100mm;

[0070] Magnesium phosphate cement is prepared by putting magnesium oxide, phosphate and modifier into a ball mill for pulverization and mixing to obtain MPC dry powder. , magnesite or dolomite ore calcined inactive magnesium oxide powder, the phosphate is potassium dihydrogen phosphate, the modifier is citric acid, magnesium oxide, phosphate and modifier in the MPC dry powder The particle size of the modifier is all less than 75 μm, and the mass ratio of the magnesium oxide, the phosphate, and the modifying agent is 1.5:1:0.1; adding distilled water to the MPC dry powder is mixed into a magnesium phosphate cement slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com