Rapidly-vulcanized ethylene-propylene-diene monomer and preparation method thereof

A technology for vulcanizing ternary and ethylene-propylene rubber, applied in the rubber field, can solve the problems of poor fluidity, insufficient scorch safety, slow vulcanization speed, etc., and achieve the effect of reducing vulcanization time, excellent performance such as shock resistance, and improving vulcanization speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

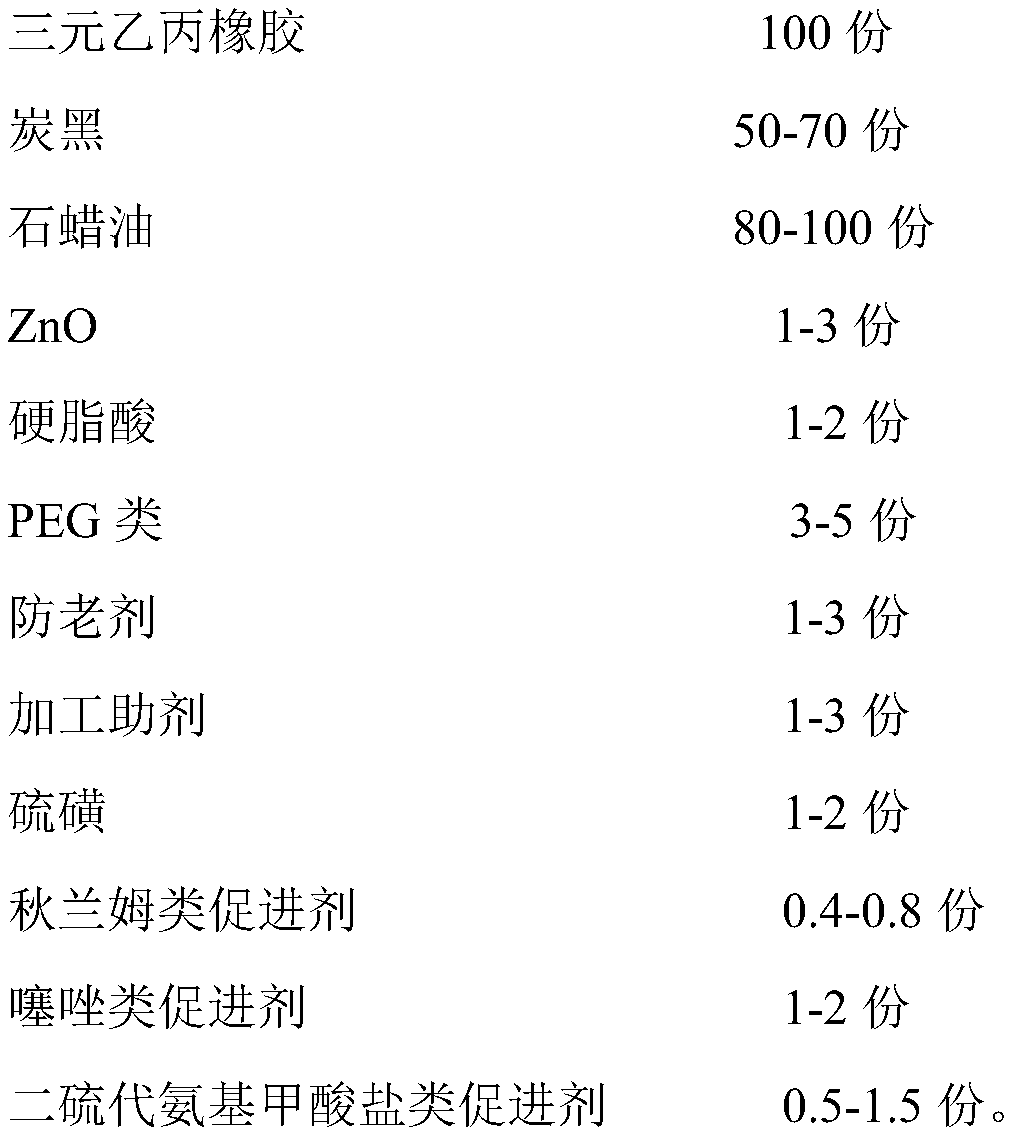

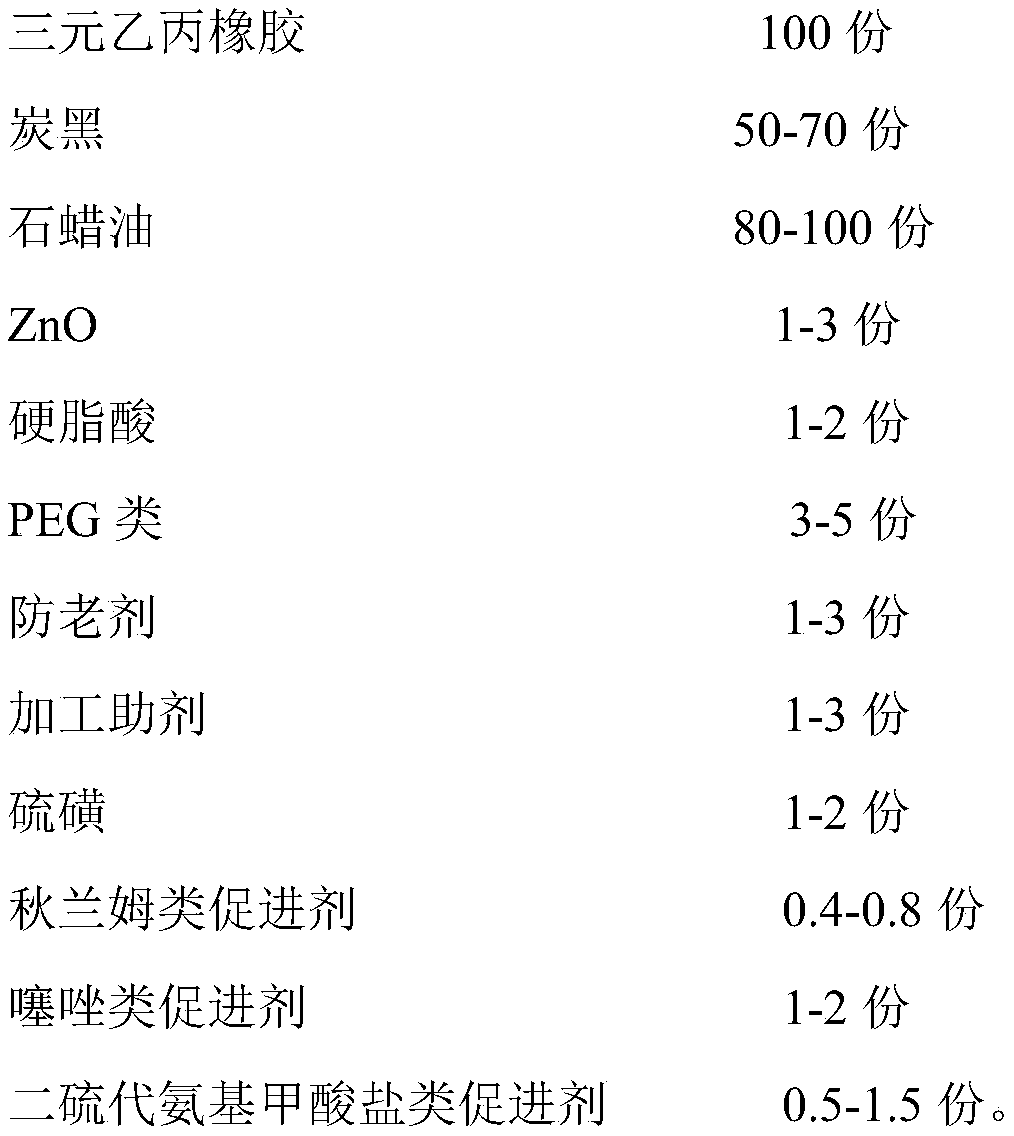

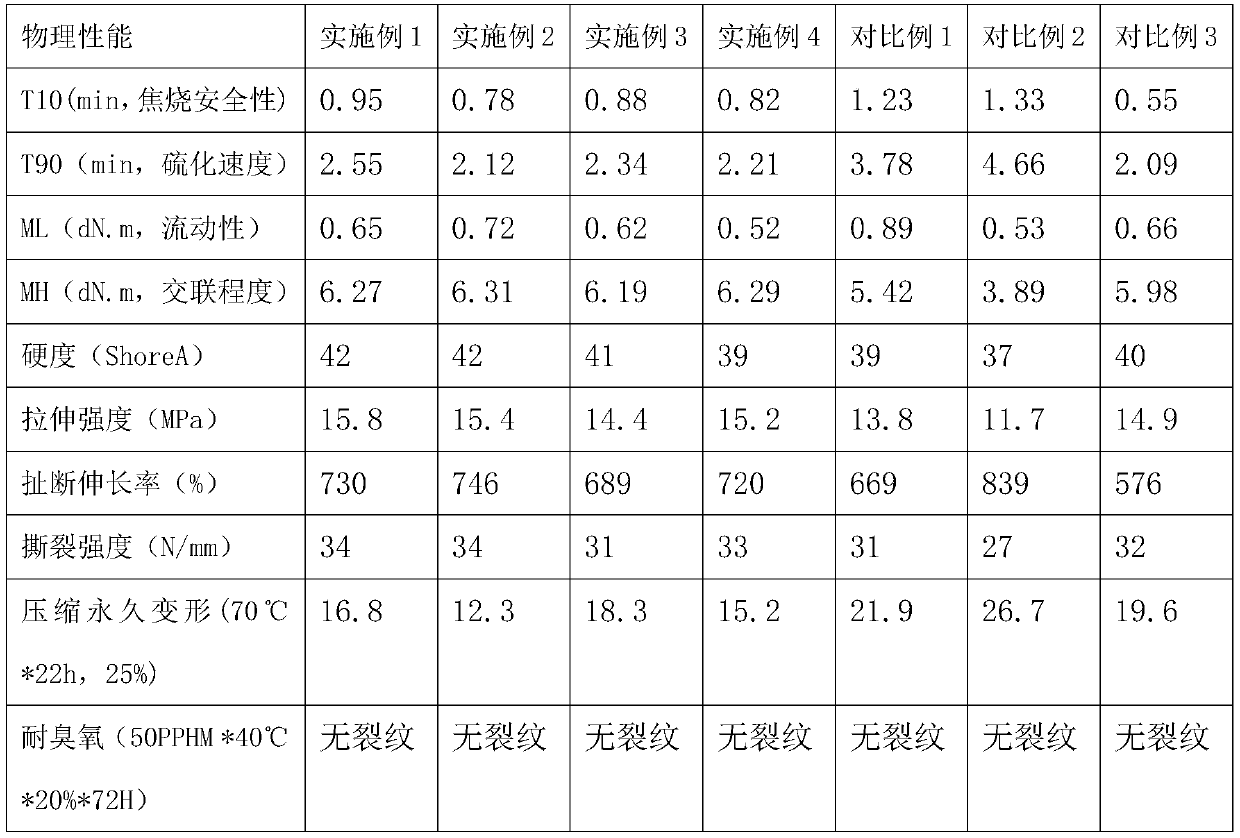

[0023] A rapid vulcanization EPDM rubber, comprising the following raw materials in parts by weight: 100 parts of EPDM rubber, 50 parts of carbon black, 95 parts of paraffin oil, 2 parts of ZnO, 2 parts of stearic acid, PEG 3.5 parts, 2 parts of anti-aging agent, 1.5 parts of flow aid, 2 parts of sulfur, 0.4 parts of thiuram accelerator TMTD, 1.5 parts of thiazole accelerator DM, 0.5 part of dithiocarbamate accelerator TDEC.

[0024] Adopt above-mentioned raw material to prepare the preparation method of rapid vulcanization EPDM rubber, comprise the steps:

[0025] (1) Internal mixing: first put in EPDM rubber, ZnO, PEG, anti-aging agent, processing aid, stearic acid, then put in carbon black and paraffin oil after 1-2 minutes, and mix until 130-140°C Glue; The rubber is left to stand for 24 hours, then the rubber is put into the internal mixer and added sulfur, thiuram accelerator TMTD, thiazole accelerator DM, dithiocarbamate accelerator TDEC, mixing 2- Deglue after 3 minut...

Embodiment 2

[0030] A rapid vulcanization EPDM rubber, comprising the following raw materials in parts by weight: 100 parts of EPDM rubber, 70 parts of carbon black, 100 parts of paraffin oil, 1 part of ZnO, 1 part of stearic acid, PEG 4 parts, 3 parts of anti-aging agent, 1 part of flow aid, 1 part of sulfur, 0.6 parts of thiuram accelerator TMTD, 2 parts of thiazole accelerator DM, 1.5 parts of dithiocarbamate accelerator TDEC.

[0031] Adopt above-mentioned raw material to prepare the preparation method of rapid vulcanization EPDM rubber, comprise the steps:

[0032] (1) Internal mixing: first put in EPDM rubber, ZnO, PEG, anti-aging agent, processing aid, stearic acid, then put in carbon black and paraffin oil after 1-2 minutes, and mix until 130-140°C Glue; The rubber is left to stand for 24 hours, then the rubber is put into the internal mixer and added sulfur, thiuram accelerator TMTD, thiazole accelerator DM, dithiocarbamate accelerator TDEC, mixing 2- Deglue after 3 minutes;

[...

Embodiment 3

[0037] A rapid vulcanization EPDM rubber, comprising the following raw materials in parts by weight: 100 parts of EPDM rubber, 60 parts of carbon black, 90 parts of paraffin oil, 3 parts of ZnO, 1.5 parts of stearic acid, PEG 3 parts, 1 part of anti-aging agent, 2 parts of flow aid, 1.5 parts of sulfur, 0.8 parts of thiuram accelerator TMTD, 1.5 parts of thiazole accelerator DM, 1 part of dithiocarbamate accelerator TDEC.

[0038] Adopt above-mentioned raw material to prepare the preparation method of rapid vulcanization EPDM rubber, comprise the steps:

[0039] (1) Internal mixing: first put in EPDM rubber, ZnO, PEG, anti-aging agent, processing aid, stearic acid, then put in carbon black and paraffin oil after 1-2 minutes, and mix until 130-140°C Glue; The rubber is left to stand for 24 hours, then the rubber is put into the internal mixer and added sulfur, thiuram accelerator TMTD, thiazole accelerator DM, dithiocarbamate accelerator TDEC, mixing 2- Deglue after 3 minutes;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com