Coal mine impact ground pressure prevention structure and method

A technology for rock burst and coal mines, which is applied in the field of coal mine rock burst prevention and control structures, can solve problems such as uncertain effects, incomplete clarity of rock burst, and failure to fully consider the influence of remote force sources, so as to achieve prevention and control of rock burst, The effect of preventing rock burst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

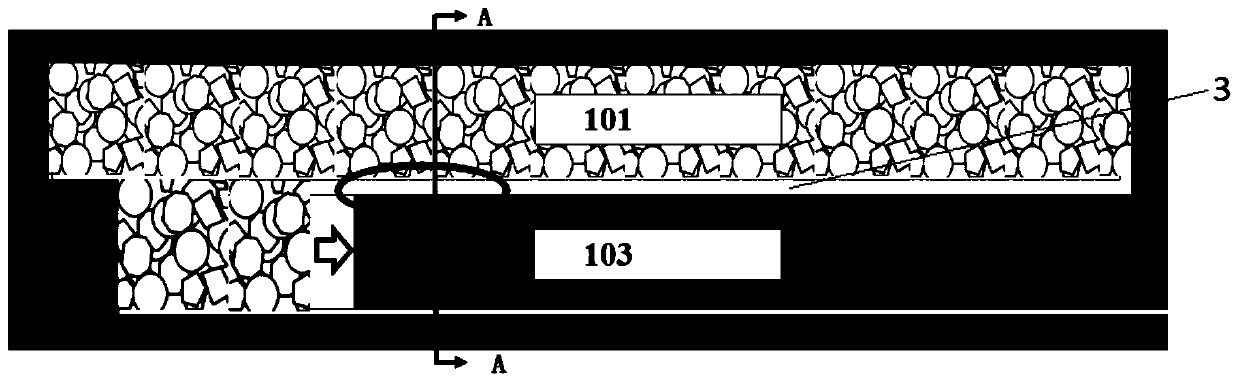

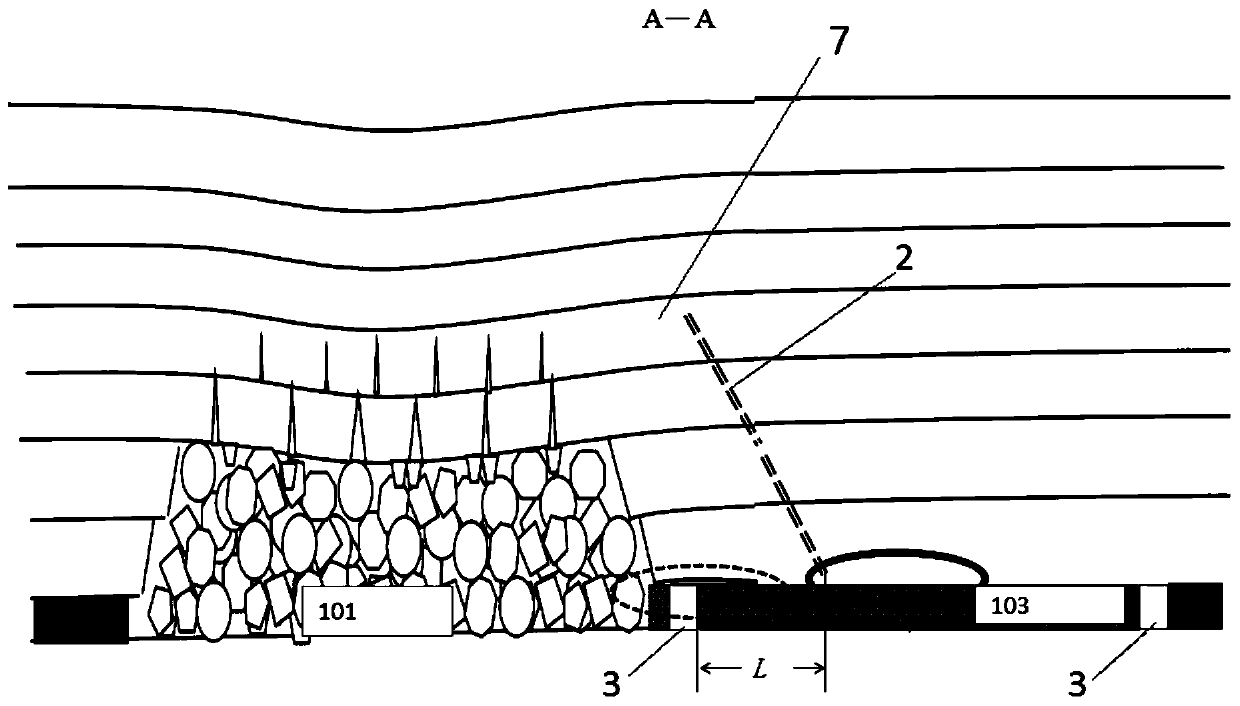

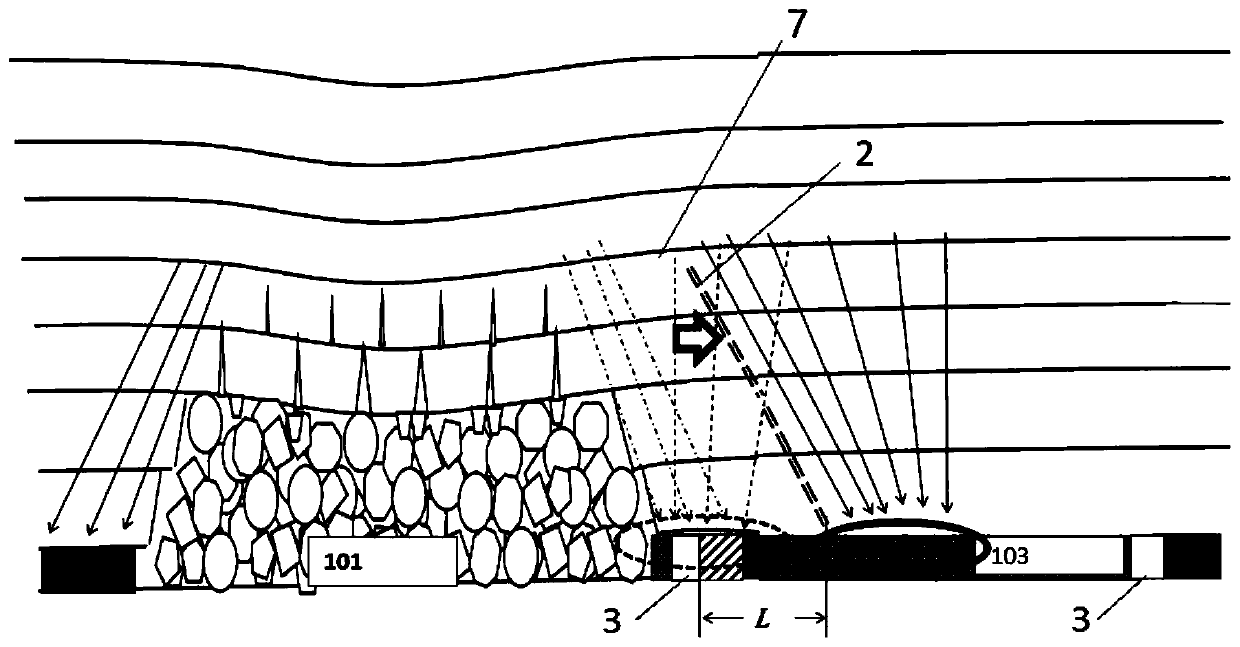

[0042] Such as Figure 1-7As shown, a coal mine rock burst prevention and control structure includes a first coal seam working face 101, a second coal seam working face 103 and a coal mining roadway 3, and the coal mining roadway 3 is located between the first coal seam working face 101 and the second coal seam working face 103 Among them, the coal seam of the first coal seam working face 101 has been fully mined, and the coal seam in the second coal seam working face 103 is being recovered, and it is characterized in that it also includes a fracture gap zone 2, and the fracture gap zone 2 is located in the second coal seam working surface. In the rock formation 7 above the face 103 , the fracture void zone 2 is parallel to the extension direction of the coal mining roadway 3 and inclined toward the first coal seam working face 101 .

[0043] The beneficial effect of this embodiment is: the stratum above the first coal seam working face that has been mined will collapse, formi...

Embodiment 2

[0045] Such as Figure 1-7 As shown, a coal mine rock burst prevention and control structure includes a first coal seam working face 101, a second coal seam working face 103 and a coal mining roadway 3, and the coal mining roadway 3 is located between the first coal seam working face 101 and the second coal seam working face 103 Among them, the coal seam of the first coal seam working face 101 has been fully mined, and the coal seam in the second coal seam working face 103 is being recovered, and it is characterized in that it also includes a fracture gap zone 2, and the fracture gap zone 2 is located in the second coal seam working surface. In the rock formation above the face 103 , the fracture void zone 2 is parallel to the extension direction of the coal mining roadway 3 and inclined toward the first coal seam working face 101 .

[0046] The stratum above the first coal seam working face 101 that has been mined will collapse, forming collapse zones, fissure zones and bendi...

Embodiment 3

[0062] Such as Figure 1-7 As shown, a method for preventing and controlling rock burst in coal mines, forming the above-mentioned structure for preventing and controlling rock burst in coal mines, and a method for forming a fracture gap zone include steps:

[0063] S11: Excavate a rock formation auxiliary roadway 4 parallel to the coal mining roadway 3 in the upper rock formation 7 of the second coal seam working face 103;

[0064] S12: In the auxiliary rock formation 4 formed in S11, drill holes obliquely upward to form the first fracture hole and / or drill obliquely downward to form the second fracture hole, the first fracture hole and the second fracture hole are set correspondingly, and the second fracture hole The length directions of the first fracture hole and the second fracture hole are both inclined towards the first coal seam working face 101;

[0065] S13: Form a fracture void zone 2 in the first fracture hole and / or the second fracture hole in a fracturing manner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com